Get daily insight, inspiration and deals in your inbox

Get the hottest deals available in your inbox plus news, reviews, opinion, analysis and more from the TechRadar team.

Explore TechRadar

Reviews

All reviews-

The Hisense U9N 4K TV is mini-LED taken to the max, with powerful built-in Dolby Atmos sound too – Samsung should be worried

Our hands-on test of the new Hisense U9N reveals a mini-LED TV primed to do battle with premium brands, but at a much lower cost.

-

-

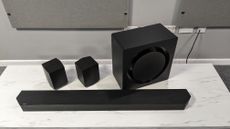

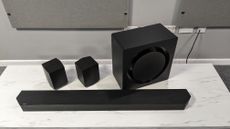

Samsung Q990D review: the best Dolby Atmos soundbar, and now perfect for PS5 and Xbox Series X, too

The Samsung HW-Q990D offers the best Dolby Atmos experience you can get from a soundbar - and it's also ideal for gamers.

-

BenQ X300G review: a budget 4K projector for gaming and movies

The BenQ X300G is a capable projector with the visual quality it needs for the home theater and the speed it needs for gaming. It offers a lot at a compelling price.

-

Samsung Galaxy Tab S9 FE Plus review: this anti-iPad Air is super-slick

The Galaxy Tab S9 FE Plus isn’t a bargain tablet, instead it’s feature-packed and ready to take on the iPad Air in almost every way.

-

Review

ReviewSony FE 16-25mm F2.8 G review: small and mighty?

The Sony FE 16-25mm F2.8 G has a super-short zoom range, but is it worth it for its small size and constant f/2.8 aperture?

-

MSI Titan 18 HX review

The MSI Titan 18 HX is possibly the most powerful gaming laptop on the planet, but its price tag puts it into a class of its own.

-

Opal Tadpole webcam: A gorgeous design with a Sony mirrorless camera

A 1080p webcam with good video quality and a directional microphone - super-portable for those on the go.

-

How TechRadar tests

Product testing for the real world

You need to know that the device or service you’re about to spend money on works as advertised - and that it works in the real world.

- We test properly: objective and subjective testing

- We use experienced experts for our reviews

- We always offer 100 per cent unbiased, independent opinions

reviews

hours' testing

buying guides

Phones

All Phones-

Huge Google Pixel 8a leak includes all the predicted specs – and a price

We're getting closer to the Pixel 8a reveal, and a newly leaked specs list covers all the details.

-

-

Updated

UpdatediPhone 16 Pro: latest news, rumors and everything we know so far

Here's everything we've heard so far about Apple's rumored iPhone 16 Pro device, from its release date to its features.

-

Sony Xperia 1 VI leak reveals new camera app and more features borrowed from Alpha cameras

New information claims the Xperia camera app is changing and its main lens will have a new image sensor.

-

Samsung Galaxy AI compatibility explained: which phones are getting which features?

We round up the Samsung Galaxy devices which are (or soon will be) compatible with Galaxy AI.

-

The Samsung Galaxy S22, Z Flip 4, and many other phones now have Galaxy AI

One UI 6.1 is rolling out to numerous Samsung phones, complete with a suite of Galaxy AI features.

-

Updated

UpdatedBest Honor phones 2024: the top Honor handsets you should consider

If you're looking for a new smartphone, one of the best Honor phones may be a good fit for you.

-

The best Samsung Galaxy S23 deals for May 2024: free devices, cheap plans

You'll find all of this week's best Samsung Galaxy S23 deals right here - perfect if you're looking to upgrade to this fantastic Android flagship.

-

Laptops & Computing

All Laptops & Computing-

NYT Wordle today — answer and hints for game #1051, Sunday, May 5

Looking for Wordle hints? We can help. Plus get the answers to Wordle today and yesterday.

-

-

NYT Strands today — hints, answers and spangram for Sunday, May 5 (game #63)

Looking for NYT Strands answers and hints? Here's all you need to know to solve today's game, including the Spangram.

-

Quordle today – hints and answers for Sunday, May 5 (game #832)

Looking for Quordle clues? We can help. Plus get the answers to Quordle today and past solutions.

-

I was fed up with creative blocks, and I found the perfect app to help me do something about it

Messier is a free and easy-to-use app that provides an abundance of creative lessons.

-

Microsoft improves File Explorer in Windows 11 testing, but appears to have second thoughts about some Copilot ideas

There are some important changes for Windows 11’s interface here – and some backtracking on Copilot.

-

There's only one good way to celebrate Star Wars day, and that's with these Meta Quest 3 games and apps

Want to enjoy Star Wars day the right way? Check out these VR games and apps that'll immerse you in a Galaxy far far away.

-

Data breaches

Data breachesHow does a data breach affect you and why should you care?

Hackers are hungry for your data, but does it really matter if they get their hands on it via a breach? Spoiler: yes.

-

Apple

All Apple-

Updated

UpdatediPhone 16 Pro: latest news, rumors and everything we know so far

Here's everything we've heard so far about Apple's rumored iPhone 16 Pro device, from its release date to its features.

-

-

New report hints at the new iPads set to be unveiled by Apple on May 7

Bloomberg's Mark Gurman gives us a full rundown of the hardware that's being unveiled on Tuesday.

-

Siri forgot how to tell the time on the HomePod – and that shows how much it needs an AI upgrade

Siri’s HomePod-based time-telling woes are a clear sign it needs an AI upgrade.

-

Tim Cook explains why Apple’s generative AI could be the best on smartphones – and he might have a point

Tim Cook believes Apple’s upcoming artificial intelligence has an ‘advantage’ that its AI rivals can’t match.

-

A key Apple Watch health feature just got a landmark stamp of approval

Regulators in the US say the atrial fibrillation history feature can be used to assess other devices.

-

Streaming

All Streaming-

The Boys season 4 trailer reveals ties to Gen V, Supe-d up farm animals, and a battle for America's soul

The popular Prime Video series received a new trailer ahead of season 4's arrival in June – and it looks as diabolically gory as ever.

-

-

Everything leaving Netflix in May 2024

In addition to bringing fresh titles to the platform, Netflix is also getting ready to remove more movies and shows. Here's a full list of everything leaving Netflix in May 2024.

-

Everything leaving Hulu in May 2024

A new month means that another shedload of entertainment is leaving Hulu. Here’s your full list of titles being removed in May 2024.

-

Everything new on Prime Video in May 2024

Prime Video's May schedule packs over 100 movies and shows instantly to keep you entertained. Here's the full list of everything coming to Prime Video this month.

-

Updated

UpdatedThe Bear season 3: everything we know about the hit Hulu show's return

Here's everything you need to know about The Bear season 3, the multi-award-winning Hulu show's confirmed next entry.

-

TVs

All TVs-

-

The Hisense U9N 4K TV is mini-LED taken to the max, with powerful built-in Dolby Atmos sound too – Samsung should be worried

Our hands-on test of the new Hisense U9N reveals a mini-LED TV primed to do battle with premium brands, but at a much lower cost.

-

Samsung Q990D review: the best Dolby Atmos soundbar, and now perfect for PS5 and Xbox Series X, too

The Samsung HW-Q990D offers the best Dolby Atmos experience you can get from a soundbar - and it's also ideal for gamers.

-

BenQ X300G review: a budget 4K projector for gaming and movies

The BenQ X300G is a capable projector with the visual quality it needs for the home theater and the speed it needs for gaming. It offers a lot at a compelling price.

-

The LG C4 OLED has just been released and it's already discounted at Amazon

Even we're surprised - the latest LG C4 OLED has just been released but there are already great deals available.

-

Updated

UpdatedThe best gaming TV for 2024

Our guide to finding the best gaming TV for your PS5, Xbox Series X, PC or even last-gen console that will suit all budgets.

-

Updated

UpdatedThe best 55-inch 4K TVs 2024

Don't settle for less than the best 55-inch 4K TVs, with great pictures, upscaling, interfaces, and audio all in one brilliant package.

-

Walmart's leaked 4K streaming box could be a serious Chromecast rival

An unboxing of an as-yet-unannounced Google TV streaming device has appeared on YouTube.

-

Audio

All Audio-

-

I heard Magico’s big new M7 speakers and now I cannot save $560k quick enough

Magico has taken most of its incredible M9 and finessed it to form the slightly smaller 'baby reference' M7 – and I need them.

-

Best Apple Memorial Day sales 2024: date and best early deals

Your guide to this year's Memorial Day Apple sales event, with key information such as the date and deals to expect.

-

Spotify is moving lyrics behind a paywall in a likely bid to lure subscribers to its rumored Hi-Fi tier

Spotify's free tier appears to be losing a key feature as the streamer gears up for the launch of a more expensive subscription.

-

Spotify Supremium leak reveals what the new tier and some features may look like at launch

Images show Spotify Supremium could have a compatibility checker to see if your phone can run hi-res audio and the tier might get a new name.

-

Bose launches its biggest Bluetooth speaker yet for beefy barbecue tunes

Bose has launched its biggest Bluetooth speaker so far, the SoundLink Max, and it could be a new premium contender.

-

The best noise cancelling headphones 2024

We've rounded up the best noise cancelling headphones that will keep the world out and your music in.

-

Bose's best headphones and earbuds tumble to record-low prices at Amazon

Amazon is running a massive Bose sale featuring the lowest prices we've ever seen for top-rated headphones and earbuds.

-

Health & Fitness

All Health & Fitness-

-

Save up to $60 on Theragun massage guns at Best Buy, and soothe post-workout aches for less

BestBuy is listing some unmissable deals on Therabody's massage gun range. Here are the ones we think you should go for.

-

A key Apple Watch health feature just got a landmark stamp of approval

Regulators in the US say the atrial fibrillation history feature can be used to assess other devices.

-

My Apple Watch's ear-splitting alarm went off in the gym – don't make the same mistake I did

I love using my Apple Watch in the gym, but it has one embarrassing problem

-

Cameras

All Cameras-

-

Huge Nikon camera sale drops Z8, Z5, Z7 II, and more to record-low prices

Adorama, B&H Photo, and the official Nikon store have just listed a huge range of discounts - including the lowest prices yet on some of the best Nikon cameras.

-

Review

ReviewSony FE 16-25mm F2.8 G review: small and mighty?

The Sony FE 16-25mm F2.8 G has a super-short zoom range, but is it worth it for its small size and constant f/2.8 aperture?

-

Canon cameras and lenses just got a lot cheaper thanks to these big cashback deals

There's up to $500 / £780 off Canon's range of mirrorless cameras and lenses in the US and UK with new cashback deals.

-

Nikon Z 28-400mm f/4-8 VR review: your one travel lens

Does Nikon’s compact all-purpose superzoom lens for its full-frame mirrorless Z-mount cameras possess the requisite X factor?

-

Home

All Home-

-

These air fryer Nutella toast pies are the ultimate comfort snack

Here's how to make Nutella toast pies that are the perfect snack, any time of day.

-

Siri forgot how to tell the time on the HomePod – and that shows how much it needs an AI upgrade

Siri’s HomePod-based time-telling woes are a clear sign it needs an AI upgrade.

-

Homey’s new smart light update is a game-changer for your mismatched smart home

The new Homey app update brings new synchronization tools to your home, letting you set Moods with different smart bulb brands.

-

Think your robot vacuum is impressive? This one can swim

The Beatbot AquaSense is a submarine robovac for your swimming pool.

-

Buying guides

All Buying Guides-

Updated

UpdatedThe best gaming TV for 2024

Our guide to finding the best gaming TV for your PS5, Xbox Series X, PC or even last-gen console that will suit all budgets.

-

-

Updated

UpdatedThe best 55-inch 4K TVs 2024

Don't settle for less than the best 55-inch 4K TVs, with great pictures, upscaling, interfaces, and audio all in one brilliant package.

-

Updated

UpdatedThe best antivirus software 2024

Whether you need protection for one device or comprehensive coverage for the whole household, I've compared the best antivirus options out there.

-

Updated

UpdatedThe best gaming laptops 2024

We've tested dozens of laptops for gaming, covering all shapes, sizes and prices, to put together our definitive list of the best gaming laptops you can buy today.

-

Updated

UpdatedBest Honor phones 2024: the top Honor handsets you should consider

If you're looking for a new smartphone, one of the best Honor phones may be a good fit for you.

-

Buying guide

Buying guideBest PS5 controllers in 2024

We're rounding up all the best PS5 controllers around from the official options to third-party powerhouses.

-

Buying Guide

Buying GuideBest PS4 games 2024 - the essentials on PlayStation 4 you shouldn't miss

The best PS4 games give you the best experience on the console and demonstrate why the console was a global multimillion-seller.

-

Why we're experts

We care passionately about tech

The TechRadar team has a life-long passion for the latest innovations – over 300 years of experience between us, in fact – and we’ve made it our mission to share that combined knowledge and expertise with you.

We’re here to provide an independent voice that cuts through all the noise to inspire, inform and entertain you; ensuring you get maximum enjoyment from your tech at all times. Technology is our passion, so let us be your expert guide.

years' experience

how-tos written

Apple events covered

Deals

All Deals-

-

Huge Nikon camera sale drops Z8, Z5, Z7 II, and more to record-low prices

Adorama, B&H Photo, and the official Nikon store have just listed a huge range of discounts - including the lowest prices yet on some of the best Nikon cameras.

-

Save up to $60 on Theragun massage guns at Best Buy, and soothe post-workout aches for less

BestBuy is listing some unmissable deals on Therabody's massage gun range. Here are the ones we think you should go for.

-

The LG C4 OLED has just been released and it's already discounted at Amazon

Even we're surprised - the latest LG C4 OLED has just been released but there are already great deals available.

-

Best Apple Memorial Day sales 2024: date and best early deals

Your guide to this year's Memorial Day Apple sales event, with key information such as the date and deals to expect.

-

Best Buy Memorial Day sale 2024: all the best early deals

Your guide to the Best Buy Memorial Day sale with all the latest news, early deals and our expert predictions for this year's event.

-

Star Wars Day 2024: The best Amazon Lego Star Wars deals for true Jedi Masters

Star Wars Day 2024 is set to be great for Star Wars and Lego fans alike. Check out these fantastic Lego Star Wars deals on Amazon

-

-

-

OnePlus Coupons for May 2024

Use these OnePlus coupons to get a better price on mobiles & accessories from the leading Android smartphone retailer.

-

Google Workspace Coupon Codes for May 2024

These Google Workspace coupon codes are here so you can make bigger savings on your plan.

-

Casper Coupons for May 2024

These Casper coupons can help you save big on your next bedding purchase from sheets, pillows, mattresses, and more.

-

Keeper Security Promo Codes for May 2024

Look through our Keeper Security promo codes to save on subscriptions to the online password manager and protect your details online for less.

-

TechRadar's story

Our mission is unchanged

TechRadar was launched in January 2008 with the goal of helping regular people navigate the world of technology. It quickly grew to become the UK's biggest consumer technology site.

Expansions into the US and Australia followed in 2012 and we are now one of the biggest tech sites in the world.

- We've been covering tech since 2008

- 17 international editions from Mexico to New Zealand

- We're a globally respected brand worldwide

Software

All Software-

-

Microsoft improves File Explorer in Windows 11 testing, but appears to have second thoughts about some Copilot ideas

There are some important changes for Windows 11’s interface here – and some backtracking on Copilot.

-

There's only one good way to celebrate Star Wars day, and that's with these Meta Quest 3 games and apps

Want to enjoy Star Wars day the right way? Check out these VR games and apps that'll immerse you in a Galaxy far far away.

-

Nearly half of all Steam users are using Windows 11 — but why?

Almost half of all Steam users have Windows 11 installed, but why do gamers love this OS so much?

-

OpenAI's Sora just made another brain-melting music video and we're starting to see a theme

OpenAI's text-to-video Sora tool has just been used in its first official music video, which hints at its strengths and weaknesses.

-

-

-

Review

ReviewGameSir Nova controller review: one step forward, one step back, but still a quality budget controller

The GameSir Nova boasts exceptional HD Rumble for Nintendo Switch, but build quality falls short of the Nova Lite.

-

This sinister Omen gaming PC build just might keep you up at night

A clever PC builder has forged a truly evil-looking gaming PC which wouldn't be out of place in an Evil Dead movie.

-

PlayStation Portal restock tracker - the latest tips on where to check for stock

We're still tracking the PlayStation Portal restock situation for you, trying to give you the best advice on where to buy the PlayStation Portal remote play device.

-

Buying Guide

Buying GuideThe best Nintendo Switch controllers in 2024

We've compiled all the best Nintendo Switch controllers to take your hybrid handheld gaming to the next level.

-

Meet Your Experts

Between them, the TechRadar team have 300 years' experience in tech journalism. Here's why you should trust them.

-

-

Acme Portable's Megapac L3 mobile powerstation comes with three 24-inch 4K screens, upgradable to six

Acme Portable's Megapac L3 mobile powerstation comes with three 24-inch 4K screens, upgradable to six.

-

University of Maine creates the world's largest 3D printer, the Factory of the Future 1.0

University of Maine has created the world's largest 3D printer called Factory of the Future 1.0.

-

Kingston Canvas React Plus V60 256GB SD Card review

The Kingston Canvas 256GB SD card offers high capacity, speed, and reliability, ideal for professional photographers and videographers.

-

SK Hynix has partnered with TSMC to produce next-gen HBM4 memory

South Korean memory giant SK Hynix has partnered with Taiwanese chip maker TSMC to produce next-gen HBM4 memory.

-