‘The robot never gets tired’: Hyundai explains why its Boston Dynamics Atlas robot is ready to take over factories, but not your home

Mass production of the Atlas robot begins this year, world domination follows

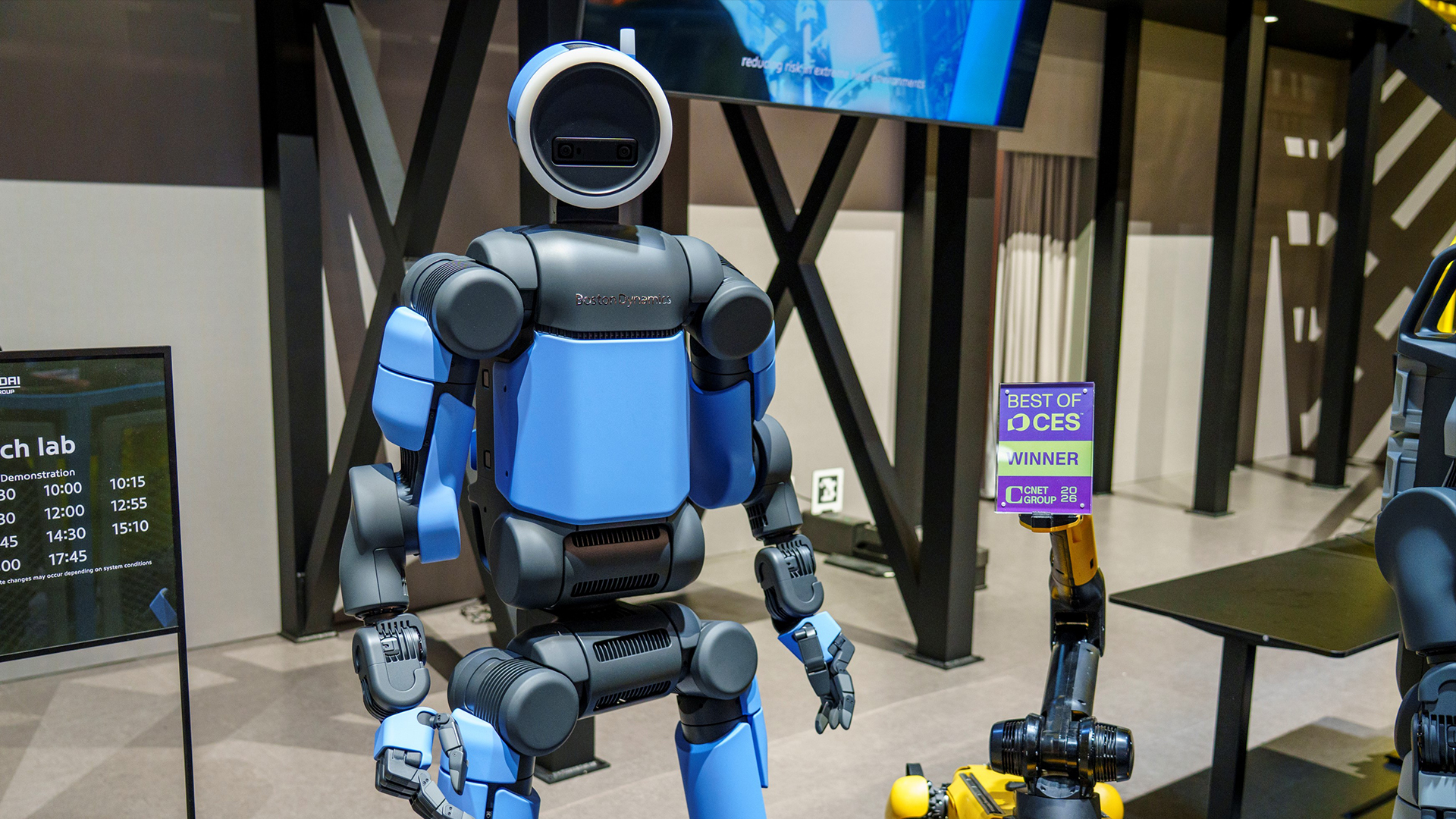

This year’s Consumer Electronics Show in Las Vegas was awash with humanoid robots. Brands used little dancing droids to attract crowds to stands, while amateur teams of engineers conducted impromptu robot-offs in the car park.

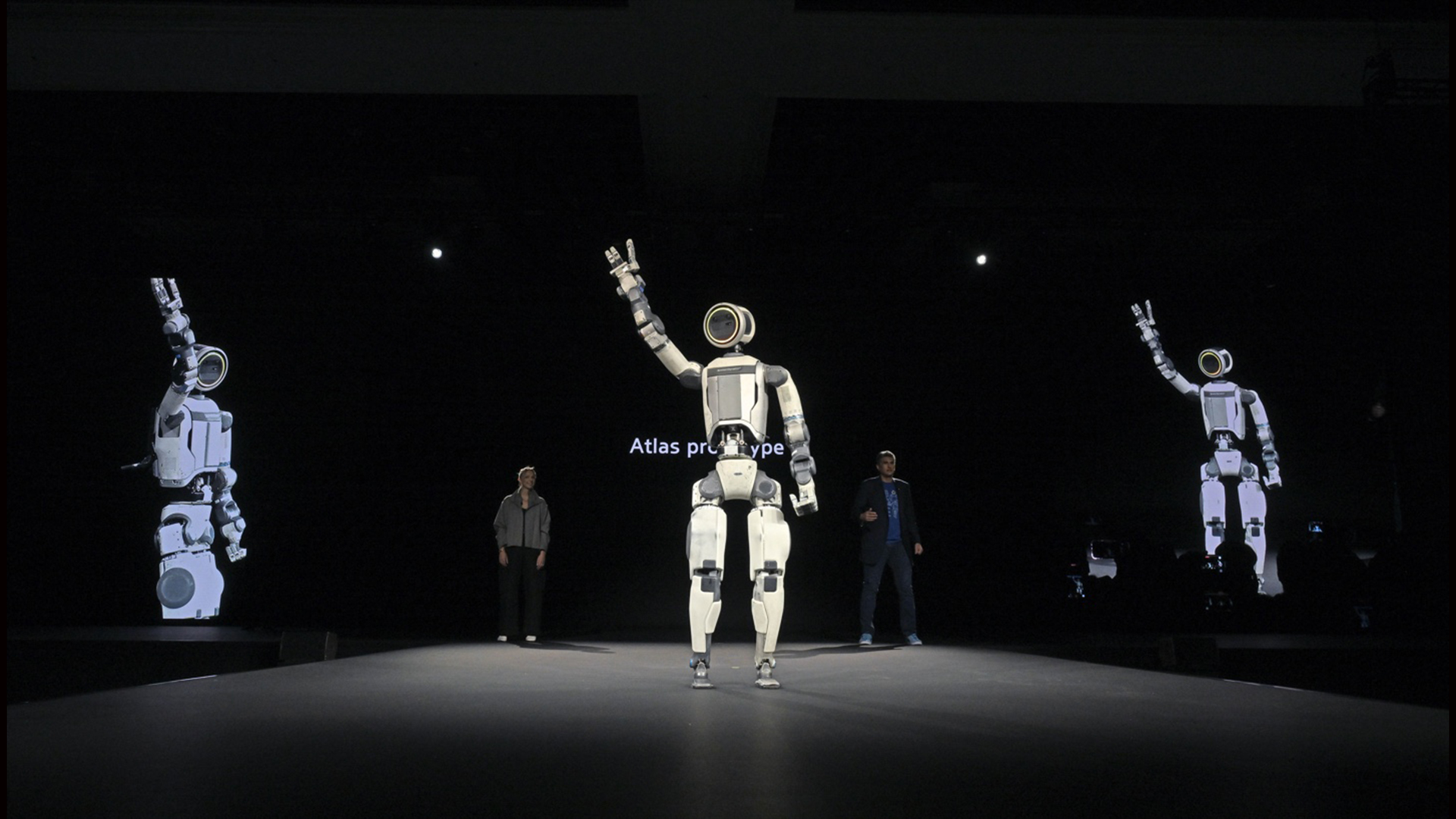

As a result, it was easy to view these often diminutive bits of technology as a novelty – until, that is, Hyundai’s 90kg Atlas humanoid robot stomped onto stage a day before the show floor opened to the public.

Measuring around 5ft tall, with the ability to reach up to heights of around 7.5ft when fully extended, Atlas is the brainchild of Boston Dynamics, the world-renowned robotics company that already has its Spot robotic dogs busy working on everything from security details to quality control shifts.

But Atlas, which is fully capable of walking (with some swagger), waving and performing the odd backflip, is an entirely different proposition and one that Hyundai Motor Group, the company that now owns an 80% stake in Boston Dynamics, hopes could prove a rich future revenue stream for the business.

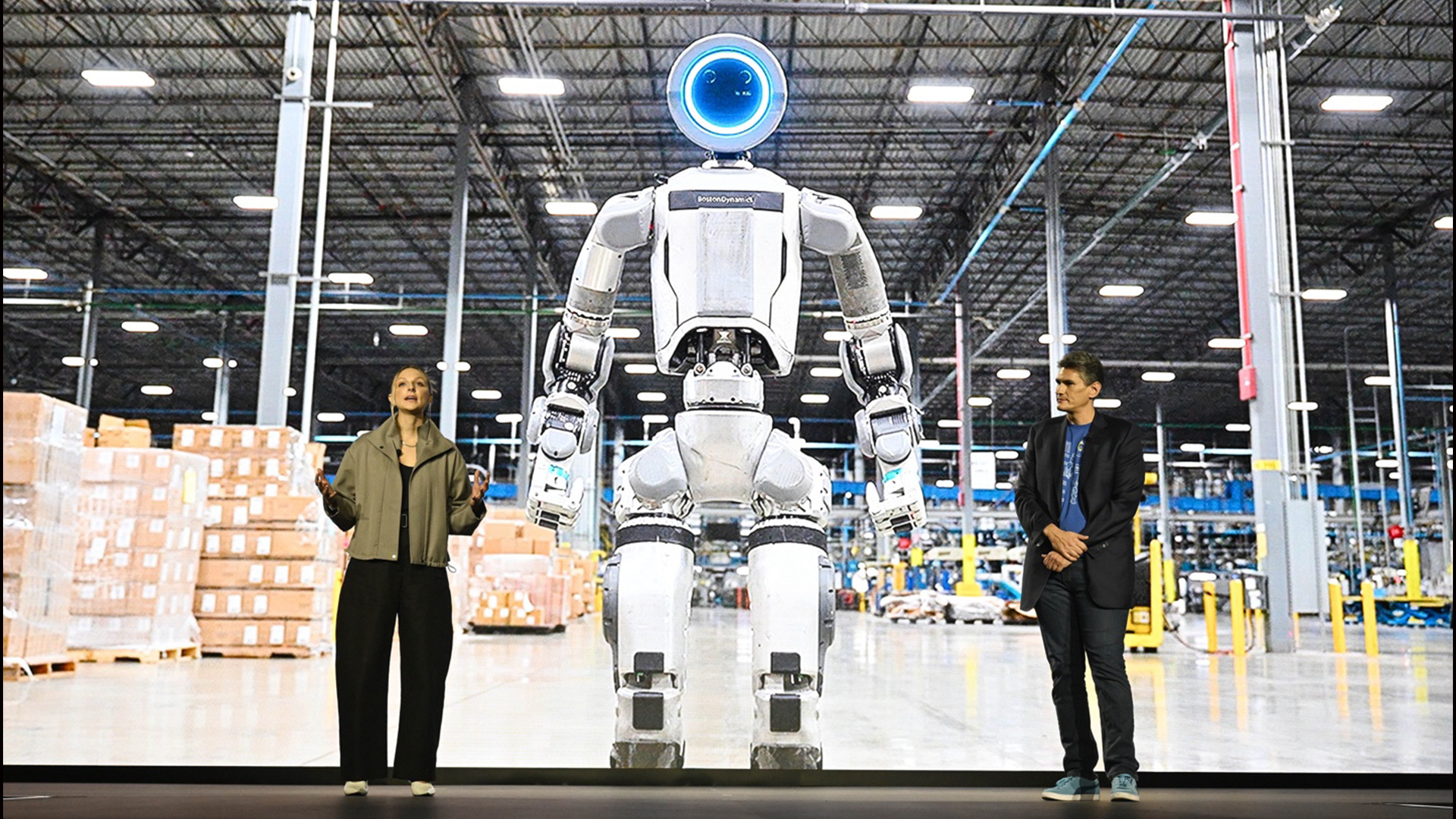

Due to begin mass production at the firm’s new Robot Metaplant Application Center (RMAC), Atlas will begin deployment across Hyundai’s various smart factories in 2028, with a view to manufacture some 30,000 units by the year 2030.

“Over the past several decades, most manufacturers have automated everything that they can automate,” explains Boston Dynamics CEO Robert Playter.

“The work that is left is difficult to automate in a cost-effective way. And that's because the tasks have huge variation. Whether it’s the parts varying from car-to-car or because the tasks involve assembly and close-knit tolerance and things that you can't do with the traditional robots,” he adds.

Sign up for breaking news, reviews, opinion, top tech deals, and more.

Consistency is key

During various demonstrations on the Hyundai booth at the Las Vegas Convention Center, which was easily one of the most popular this year, Atlas could be seen moving car parts from one storage area to another — its 56-degrees of movement allowing it swivel its entire body to move between storage bins, rather than having to walk.

Similarly, its dexterous fingers could grasp an array of objects, even down to the small and delicate stuff, and move it accurately. Weather-proofing ensures it can work outside and when its batteries run dry, it simply walks over to a charing dock and replaces them itself.

While the speed at which Atlas could perform these tasks wasn’t exactly mind-blowing, chief strategy officer at Boston Dynamics, Marc Theerman, explained to me that this wasn’t really the point.

“Humans might be super efficient at 9am in the morning, but our studies suggest that this efficiency drops off throughout the day. With this sort of automation, you need consistency, and the robot never gets tired, and the robot runs at a consistent speed with little interventions,” he explains.

In this respect, Atlas has been designed to be put to work on the sort of shifts and tasks that would have unions calling for strike action. Downtime? No way. The company ensured that most of Atlas’ parts are easily interchangeable if the worst happens.

“If an arm, a leg of even a hand is broken, these parts can be swapped by anyone with even the slightest bit of training in a matter of minutes,” Theerman says. “This was something we learnt from our Spot robot, our customers don’t want any downtime to fix robots,” he adds.

Believe the hype

While humanoid robots are currently at the very epicenter of the hype cycle, there is a valid reason for choosing this form. Theerman says that he predicts many Atlas units will be put to work in facilities that were never designed for robots in the first place.

“The average plant in Europe or the United States is probably 35 years old. And so if you want to automate a plant like that, without fixed automation, you need something that looks like a human, because that's what the plant was designed for,” he says.

A quick scan of the Boston Dynamics back catalogue reveals plenty of other robots, such as its Stretch logistics bot that is solely used for warehouse operations, that can be implemented for very specific tasks.

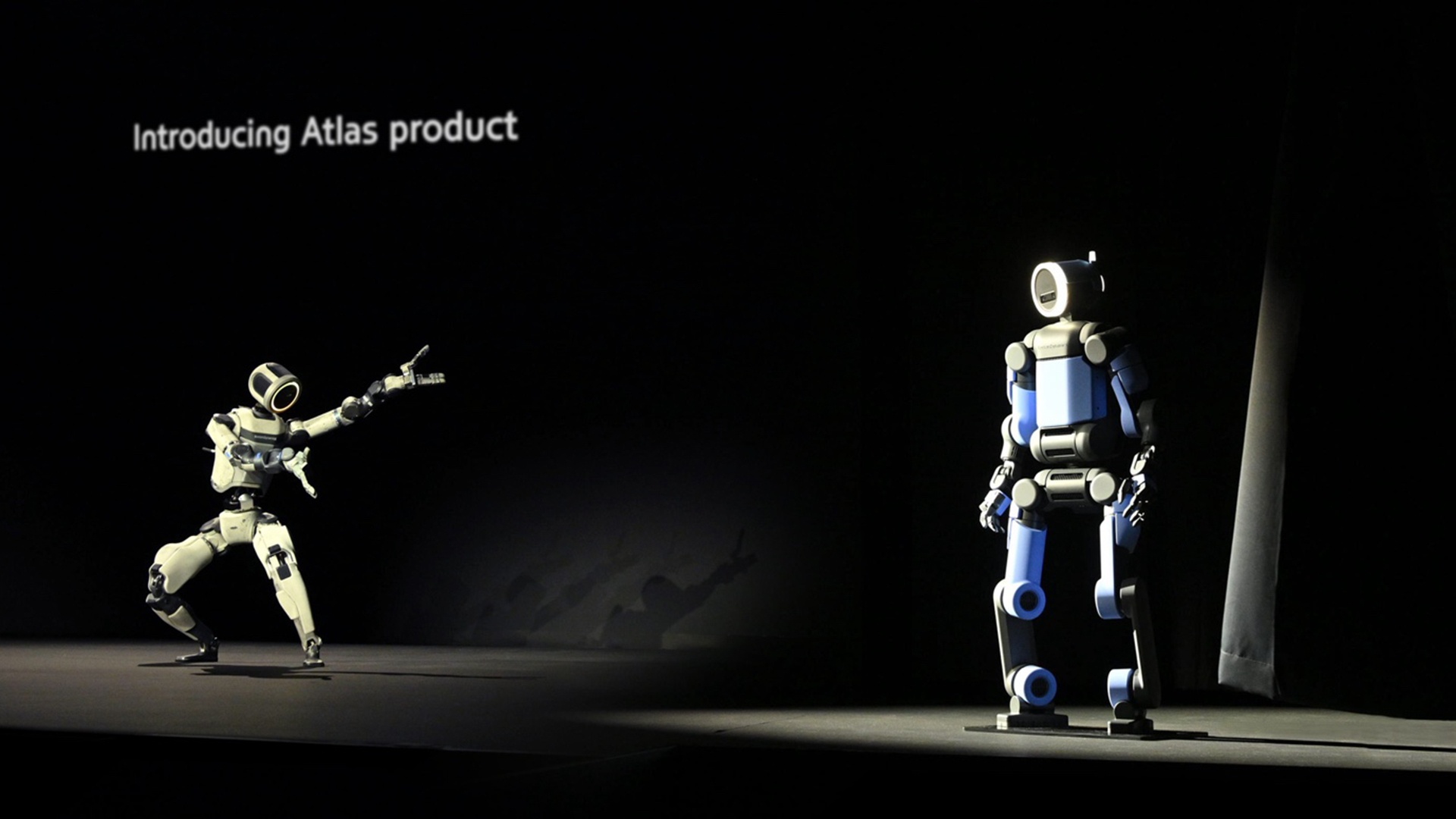

But what sets Atlas apart is the fact it can perform numerous jobs and, thanks to advances in AI and, in particular, Large Behavioral Models (something Google’s DeepMind is helping with), the humanoid will be able to be trained in a matter of days to perform complex actions.

“So far, we’ve focussed on the physical side of AI, so Atlas can dance, run and jump. But behavioral is the next frontier. We hope that in the future, customers will be able to swap the humanoid’s hands for specific tools, so it can be taught to weld, construct and much more,” Theerman adds.

At this point, it is worth noting that Hyundai’s humanoid endeavor isn’t the first of its kind, nor is it the only technology in existence. In fact, there’s a veritable arms race to launch useful robots.

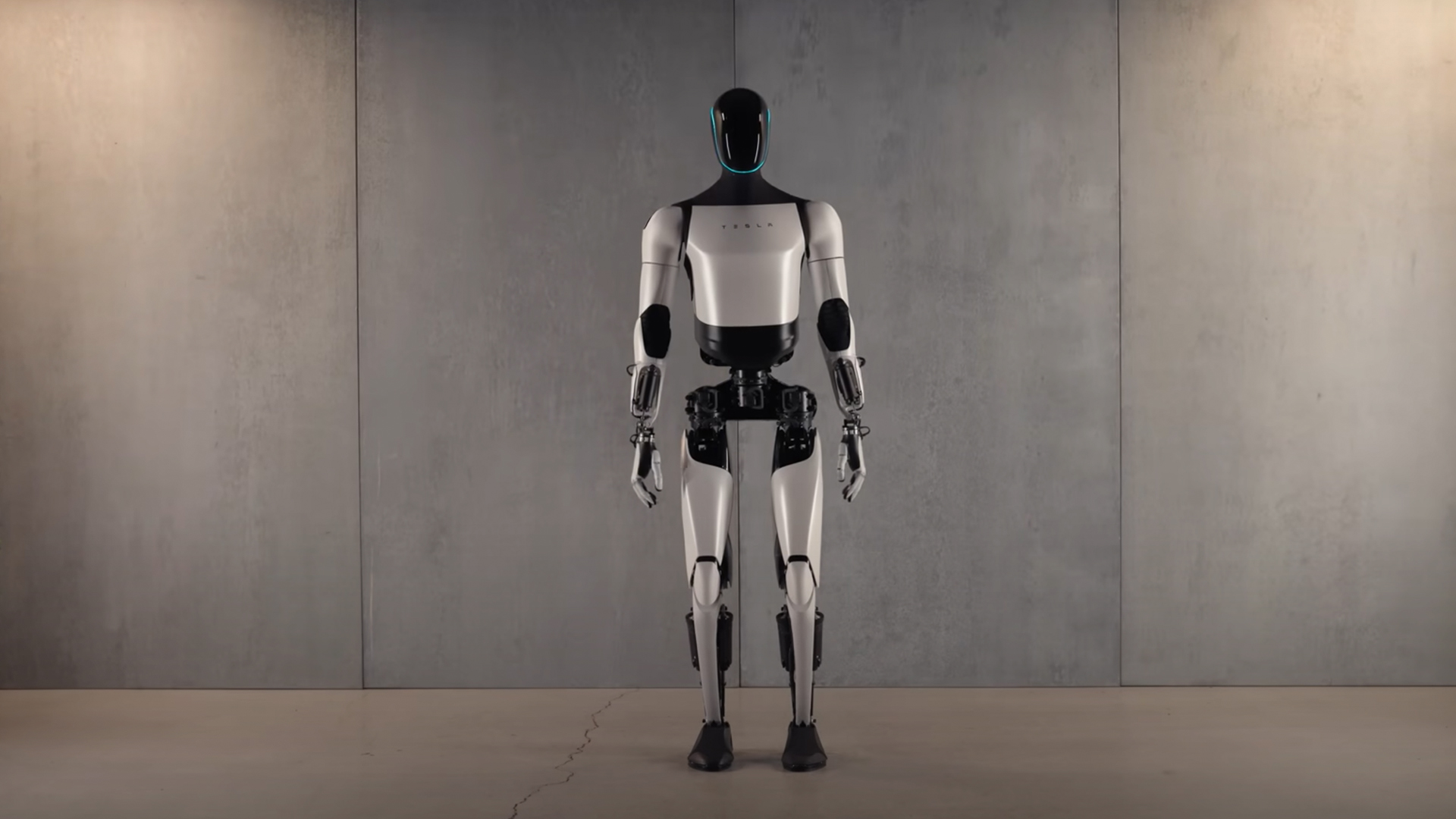

Tesla’s Optimus is designed for general purpose tasks, but early demonstrations have revealed that it still has some way to go before being genuinely useful. Similarly, companies such as Figure AI, Agility Robotics and Apptronik are all making waves in the emerging industry.

In fact, Chinese heavy equipment manufacturer Zoomlion already has a team of humanoid robots busy at work in its network of plants, churning out hundreds of products a day.

But Boston Dynamic’s CEO still thinks his company has the edge, not least because it has the financial and manufacturing backing of the Hyundai Motor Group.

“We've already got a pathway that we're cutting with our existing products to commercialize. We've built our organization around supporting products in the field, integration, service, repair, logistics, so all of the components around that. Something that thankfully nobody else is doing yet,” he says.

Oh, the humanity

The question of replacing humans is neatly brushed off by those in the business of robotics, seeing as the technology has the potential to replace vast swathes of manual labour. Thankfully, Atlas, much like its Spot counterpart, is expensive right now and many plants find it cheaper and more convenient to use a human workforce.

But Boston Dynamics’ chief strategy officer feels that, while it could be a potential issue, he has found companies with a higher robotic adoption are more productive, therefore are growing faster, are more profitable, and are hiring more employees.

“Yes, there’s going to be shift of workers, but we think that at the moment, these robots will always require human monitoring. So we call this job 'robot wrangler' or 'robot operator'. And that job is growing quite fast, and it's fascinating,” says Theerman.

And what about your robot butler? Well, the Boston Dynamics CEO thinks that is some way off. In fact, he feels robots in the home is the wrong strategy, citing the fact that the consumer market is very “cost sensitive”. He also admits that safety is paramount and that the home is a “complex environment”.

“We think it's going to be 2028 or 2030 when we have robots deployed in factories and probably five years after that before they’re really affordable in the home,” Playter states.

Mark your diaries. The year 2035 could be when we finally witness the rise of the robots, or find out if it’s just another hype cycle that will gradually fade into the CES archives.

Follow TechRadar on Google News and add us as a preferred source to get our expert news, reviews, and opinion in your feeds. Make sure to click the Follow button!

And of course, you can also follow TechRadar on YouTube and TikTok for news, reviews, unboxings in video form, and get regular updates from us on WhatsApp too.

Leon has been navigating a world where automotive and tech collide for almost 20 years, reporting on everything from in-car entertainment to robotised manufacturing plants. Currently, EVs are the focus of his attentions, but give it a few years and it will be electric vertical take-off and landing craft. Outside of work hours, he can be found tinkering with distinctly analogue motorcycles, because electric motors are no replacement for an old Honda inline four.

You must confirm your public display name before commenting

Please logout and then login again, you will then be prompted to enter your display name.