How to get started in 3D printing

What you need to know before buying a 3D printer

Maker culture, where a technology-based, DIY mantra empowers countless people every day to tinker with the world around them, has many components.

Whether it's electronics, robotics, metalworking, woodworking, food hacking, sewing, or any other number of activities, making is, at its heart, about creation. However, of all of those activities, 3D printing is arguably the maker movement's most novel development.

Led by an ever growing number of machines that allow anyone to print nearly any physical object they can imagine, it's no surprise that 3D printing is so rapidly gaining in popularity.

Unfortunately, as a technology that has had little more than a decade of mainstream accessibility, and far less than that of mainstream affordability, 3D printing still presents some challenges for the potential new owner. In this guide, we’ll attempt to demystify 3D printing, hopefully helping to turn potential new owners who might otherwise become frustrated and give up into ones who more easily transition to happy users.

What is 3D printing?

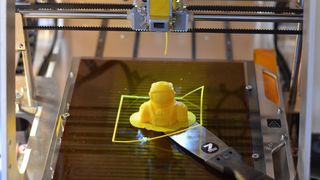

3D printing is what is known as an additive process, and is usually referred to as Fused Deposition Modeling (FDM), or sometimes Fused Filament Fabrication (FFF).

Simply put, this means that FDM printers extrude a small amount of heated material, which is typically a type of plastic, to build an object or objects layer-by-layer. While there are a small percentage of StereoLithography (SLA) printers that harden a pool of polymer liquid resin by exposing it to focused ultraviolet light, most 3D printers are of the FDM variety. Since FDM printers are the most common and the easiest to work with, they’re what we’ll focus on here.

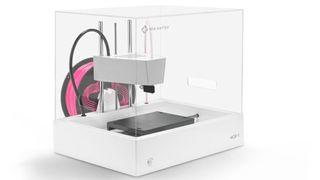

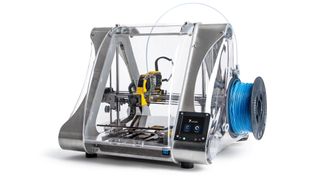

We'll be featuring two different FDM 3D printers we have on hand to illustrate many of our points, the New Matter MOD-t (currently $299, about £240, AU$405) and the ZMorph SX 2.0 (starting at $2,690, about £2,200, AU$3,500).

Get daily insight, inspiration and deals in your inbox

Get the hottest deals available in your inbox plus news, reviews, opinion, analysis and more from the TechRadar team.

The MOD-t is a consumer-friendly 3D printer with a proprietary design. The trade-off for the MOD-t's ease-of-use is limited versatility and a modest build area.

The ZMorph 2.0 SX, on the other hand, is a semi-pro 3D printer based on the open design RepRap project. It has exceptional versatility with a large build area, and is easily expandable with dual color, thick paste extruder, laser, and CNC toolheads to print, cut, engrave, and mill a wide variety of materials.

The tradeoff for this versatility is a higher cost, high learning curve, and more maintenance and troubleshooting demands.

Who is 3D printing for?

While certain media coverage may make you think otherwise, 3D printing is not just for those who call themselves a Maker. It's also for the hobbyist, crafter, tinkerer, technology enthusiast, and anyone else with a desire to create. And despite 3D printing's many practical applications, including solving some real challenges, many people purchase a 3D printer simply for the fun of it.

Whether it's cookie cutters or other household items, school projects, replacement knobs for appliances, storage solutions, hobby items, or holiday decorations, the possibilities are only limited by one's imagination.

Age isn’t a limiting factor, either. Kids in particular seem to love printing little figures of their favorite Pokémon, Steven Universe character, or any other hot pop item.

Usually there are good paid or free models available for most of this stuff, but the real fun and value comes when they design their own creations. In fact, as just one example, in the upcoming Windows 10 Creators Edition update and its Paint 3D app, thanks to 3D printing, kids (or anyone else) will be able to bring their Minecraft creations from the virtual world to the real world.

While some design software is difficult for all but the most dedicated to figure out, there are plenty of good free programs out there to help just about anyone get designing in only a few hours. The nice part about 3D printing is that you can put as little or as much effort as you want into the whole process and you'll still get something of value out of it.

3D printing isn't limited to creating solid objects either. Designs with moving parts like hinges and snaps can be created using even the most basic 3D printer.

Of course, 3D prints are also not necessarily limited by the size of a printer's build area. It's common to print complex or extra large objects in pieces, which can later be glued together. Other post processing, like sanding and painting, help further bring the print, and individual creativity, to life.

Types of 3D printers

There are as many 3D printer variations as there are price points. Whether it's a $200 (about £160, AU$260) built-it-yourself model or a $3,000 (about £2,400, AU$3,900) semi-pro model, or anything in-between, the variation in features can be overwhelming and confusing. Let's try to simplify some of this.

To start, there are two major types of FDM printer movement systems: cartesian and delta. Cartesian designs, like that found in the MOD-t and ZMorph, are the most common and use a three-axis motion system, with X for left and right, Y for front and back, and Z for up and down.

Most cartesian printers, like the ZMorph, have print beds that only move along the Y axis, while others, like the MOD-t, have print beds that move along both the X and Y axes. The latter type of design, where the actual print bed moves, is generally simpler and easier to work with, but results in slower print speeds and often has smaller print areas.

Delta printers, on the other hand, such as the Delta Go 3D Printer ($499, about £400, AU$650), use a similar three-axis motion system, but feature a stationary, circular build plate.

Instead, a delta printer's extruder is suspended by three arms and moves in all directions. The advantage to this design is increased speed and usually a greater build height (Z axis). The disadvantage to this tower-like design is typically reduced print quality and a smaller build area in the X and Y axes.

While there are some benefits to building a 3D printer from a kit, including a lower cost and the ability to become intimately familiar with the machine for when something inevitably needs troubleshooting, the reality is that's not a great option for most users, particularly beginners.

If you think a DIY option is for you, then you probably already understand and are ready to tackle the inevitable challenges such an undertaking represents. For everyone else, there are plenty of pre-built options in every price range.

Generally speaking, sub-$500 printers will be easier to use but have more limitations than printers that cost $500 or more. Some low cost printers, like the Da Vinci Mini Maker ($250, about £200, AU$325), feature an incredibly low price with great educational software, but require proprietary PLA printing filament. While the use of proprietary filament can result in more consistent output, the costs quickly add up over lower cost, generic PLA filament, negating any initial savings. A sub-$500 printer, like the MOD-t, although costing a bit more initially, has similar ease-of-use, but can utilize any PLA filament for greater long term savings.

For printers that cost more than $500, you can generally expect higher performance and more versatility. Many such printers feature interactive touchscreens and larger, heated print beds that allow for use of more types of printing materials.

Some printers even offer multiple functions beyond just 3D printing, including 3D scanning to help replicate existing objects, or, through interchangeable toolheads, features like laser cutting and engraving. The ZMorph 2.0 SX is one such printer that offers a touchscreen interface, heated print bed, and interchangeable toolheads for many different types of workflows beyond just 3D printing.

Other printer choice considerations include how you'll want to send print jobs to the printer and whether or not the print area is enclosed. In terms of printing, some machines connect over USB and need to be tethered to a computer, others can work with files saved to an SD card, while still others can work over wired LAN or Wi-Fi connections. As for our reference printers, the MOD-t supports USB and Wi-Fi, while the ZMorph supports USB, SD card, and wired LAN-based network connections.

Since 3D printing involves high temperatures, safety should be a consideration. Enclosed beds, like the one on the MOD-t, are generally quieter and better able to regulate their temperatures.

Printers like the ZMorph, which recommends removing its covers when printing PLA and putting the covers on when printing with other materials like ABS, offer greater flexibility and accessibility, but with more of its parts, including a heated print bed, exposed to curious hands.

Other printers forgo any type of cover option at all, including the aforementioned Delta Go, although its tower-like design and smaller footprint has greater placement flexibility versus more traditional designs.

Finally, in terms of print beds, or build plates, those can also vary greatly. A printer like the MOD-t uses a reusable print bed that lifts out and flexes to help with object removal. A printer like the ZMorph, on the other hand, uses a more traditional print bed that remains in place, so a metal spatula is needed to remove the object.

PLA vs ABS and other filament materials

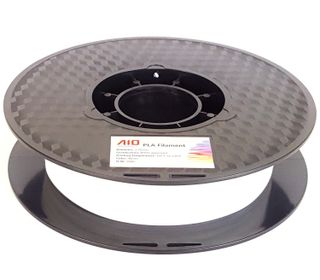

For an FDM printer, filament moves from a filament spool to an extruder, which grabs the filament and pushes it through a heating block, or hot end. The hot end extruder has a nozzle at the bottom for the molten filament to flow through onto the print bed, where the object is built up layer-by-layer.

Filament comes in one of two diameters, 2.85mm and 1.75mm, which are specific to the type of hot end extruder. The 1.75mm size is by far the most common and inexpensive, although there's no practical difference between the two diameters in actual usage.

The two major filament types are PLA (PoLyactic Acid) and ABS (Acrylonitrile Butadiene Styrene). PLA is the most common and works on every FDM printer because its build requirements are minimal. Since PLA is a plastic formulated from biodegradable sugars, it's non-toxic and low odor, with a slightly sweet aroma.

The downsides to PLA are its high surface hardness, which makes it more brittle than something like ABS. As such, PLA is best for printing objects that will not be placed under stress.

ABS requires higher extrusion temperatures and a heated print bed, and often demands additional experimentation to get consistent quality prints. It's also oil-based and smells strongly of hot plastic when extruded, so it requires a room with good ventilation. The benefits of ABS are higher durability, flexibility, and impact resistance, making it ideal for creating more demanding prints like tools and objects with moving parts.

Of course, there are many other types of filament, including Nylon (Polyamide) and composite blends to simulate wood or metal, conduct electricity, and more. Each of these other types has its own strengths, weaknesses, and printing requirements, and not everything will be compatible with your specific model or configuration of printer. In terms of our reference printers, since the MOD-t forgoes a heated print bed, it's limited to PLA and its variants. The ZMorph can accommodate nearly any material on the market.

Quality filament starts at about $10 (about £8, AU$14) for a 0.5kg spool, which is enough to print about 160 chess piece-sized objects. Prices go up dramatically from there depending upon brand, how exotic the material, and how large the spool, with 1kg spools being particularly common.

Most printers have a single extruder for printing from one filament color or type at a time. Some printers also support dual extruders for printing two different filaments of the same type (both PLA, or both ABS, for instance) at once; more than two extruders is also possible, but generally only available in oversized, higher-end printers. Many single extruder printers, like the MOD-t, can mimic some of the features of dual extruder printers by pausing prints and allowing you to swap in new filament, but it's obviously not as flexible as having immediate access to a second filament.