The best OLED TVs for all budgets, as reviewed by our experts

OLED tech means these elite TVs offer incredible contrast and no light bleed. Here are our top picks

The best OLED TVs on the market today deliver beautiful image quality thanks to the self-lighting pixels that define this technology. What these pixels deliver are stunningly deep black tones and incredibly precise contrast between light and dark areas, in a way that LED or mini-LED TVs simply cannot match. Read our 'What is OLED?' guide for more on why this tech is such a big upgrade, and so sought-after.

The best OLED TVs include a lot of models that rank among the best TVs overall, and come from the biggest TV brands, such as LG and Sony. Even Samsung – a TV company that had rejected OLED for years, has not only joined the party, but has topped our rankings here at times.

Our picks of the best OLED TVs here aren't just ranked from the best-looking to the weakest, because that would put all the most expensive ones at the top. We've tried to be more discerning and helpful, choosing the best options for different price brackets and particular needs, hopefully making it easier to find the one that fits your need best.

⭣ Read more

Why you can trust TechRadar's choices

We've tested all the TVs here ourselves, and our TV review team is led by Al Griffin, an ISF-trained video calibrator with nearly three decades of AV journalism experience. He's trained our staff writers to balance objective testing of brightness and color accuracy (measured using high-end industry-standard equipment) with the more subjective elements of picture and sound quality – because you can't judge how an image looks to the eye based on scientific measurements alone.

We're judging these TVs based not just on picture quality, but also the features they offer, and how that balances with the price. We provide ratings for each TV in the different sections we judge, as well as providing our measurements, so you can follow our decision making, and decide if your own priorities are slightly different.

Each TV is vouched for by a member of the team, who's written up why they recommended it, as well as going in-depth on what we thought based on our review.

Quick list

The best OLED TV for most people

This feature-packed OLED TV delivers stunning picture quality, excellent performance and a brightness boost over the C4, all at a competitive price. It’s an excellent value all-rounder, available in a wide range of sizes too.

The best budget OLED

If you want a more affordable OLED, but one with 120Hz and VRR for next-gen gaming, plus beautiful contrast and cinematic dark tones, this is for you. Great features, just not as bright as other options.

The best premium OLED

If you want an OLED TV that delivers breath-taking picture quality, brightness that matches mini-LED TVs, and every feature you could need, the LG G5 should be your top choice.

The best OLED TV for sound

With a powerful built-in 5.1.2 Dolby Atmos speaker system, no OLED TV beats it for audio. You don’t even need a soundbar. Picture quality is also stunning, prioritizing detail and accuracy.

The best OLED for bright rooms

The Samsung S95F's combination of high brightness levels and a new, enhanced Glare Free screen makes it the best OLED TV for bright room viewing.

October 24, 2025

Replaced the LG C4 with the newer LG C5 as our 'best for most people' pick, based on our recent testing.

Today's best OLED TVs, as chosen by our reviewers

Why you can trust TechRadar

The best OLED TV for most people

Specifications

Reasons to buy

Reasons to avoid

1-minute summary: The LG C5 OLED TV continues the tradition of affordable, mid-range greatness exemplified by its C4 predecessor, now taking its place as our best OLED TV for most people. While picture quality between the two is largely similar, a new Alpha 9 Gen 8 AI Processor here delivers a modest brightness boost, along with AI-driven picture and sound enhancements. Available in a wide range of sizes from 42 to 83 inches, the C5 suits everything from desktop gaming to your home theater. It’s a fantastic choice for gamers with a full suite of essential features, including 4K 144Hz, VRR, FreeSync Premium and Nvidia G-Sync, ALLM and Dolby Vision gaming, all across four HDMI ports. The updated webOS smart TV platform uses AI to enhance search and both picture and sound customization, and it can be personalized for multiple users in the same household, using voice recognition to switch between them. Whether it’s for gaming, movies, or everyday viewing, the LG C5 is a superb all-purpose TV that offers excellent performance and value.

Read our full LG C5 review

Reasons to buy

✅ You value versatility in an OLED TV: With picture quality that looks more premium than its price, excellent gaming features and a wide range of sizes, the C5 ticks all the boxes.

✅ You want an intuitive smart TV platform: webOS 25 is clean, responsive and easy to navigate with new AI tools that make setup, search and customization smarter than ever.

✅ You want a great gaming TV: With a full suite of gaming features, impressive performance and stunning visuals, the C5 is a perfect TV for gaming.

Reasons to avoid

❌ You already own the LG C4: The LG C5 is excellent, but its upgrades are modest. Or at least not enough to justify replacing last year’s model if that’s what you have.

❌ You want the best built-in sound: Audio performance is decent, but it doesn’t match the C5’s stellar picture quality, and some rivals do sound better straight out of the box.

❌ You need HDR10+ support: The C5 supports Dolby Vision but skips HDR10+, which is becoming a more widely used HDR format on major streaming platforms.

In-depth analysis

We measured the LG C5’s peak HDR brightness at 1,180 nits in Filmmaker Mode, which is a solid step up from the C4’s 1,065 nits. That extra brightness brings more punch to HDR highlights and adds realism to colors, which look rich and dynamic across Dolby Vision content. Shadow detail and contrast remain superb, with deep blacks and refined mid-tones in darker scenes. Upscaling is also impressive, giving HD and even standard definition sources a sharper, cleaner look. The only thing the C5 struggled a little with was screen reflections, especially when you’re watching in brighter rooms.

The LG C5 uses a 2.2-channel, 40W Dolby Atmos speaker system with no DTS support. Its updated AI Sound Pro mode can upmix audio to a virtual 11.1.2 setup, creating a wider and more immersive soundstage than the C4. During testing, we particularly enjoyed using the TV’s AI Sound Pro mode, which enhanced every aspect of the audio, producing a brighter overall sound that may not suit everyone but we found it more engaging and immersive. The new AI Sound Wizard allows for personalized audio profiles, offering welcome customization even if some of the profiles didn’t quite hit the mark. Overall, sound quality is good, but pairing the C5 with one of the best Dolby Atmos soundbars is the ideal way to match its excellent picture performance.

The LG C5 runs on webOS 25, which builds on its predecessor with a host of new AI tools, including AI Search, AI Concierge and AI Art. The upgraded Chatbot can now offer quick advice on picture or sound settings, though it struggles with more complex questions. Voice ID is a standout new addition, automatically recognizing who’s speaking and then switching to their personalized profile and recommendations. Quick Cards remain a handy way to organize apps by category, while the layout of webOS 25 is clean and easy to navigate. The Quick Menu is still a strong feature, letting you tweak settings on the fly without interrupting what you’re watching.

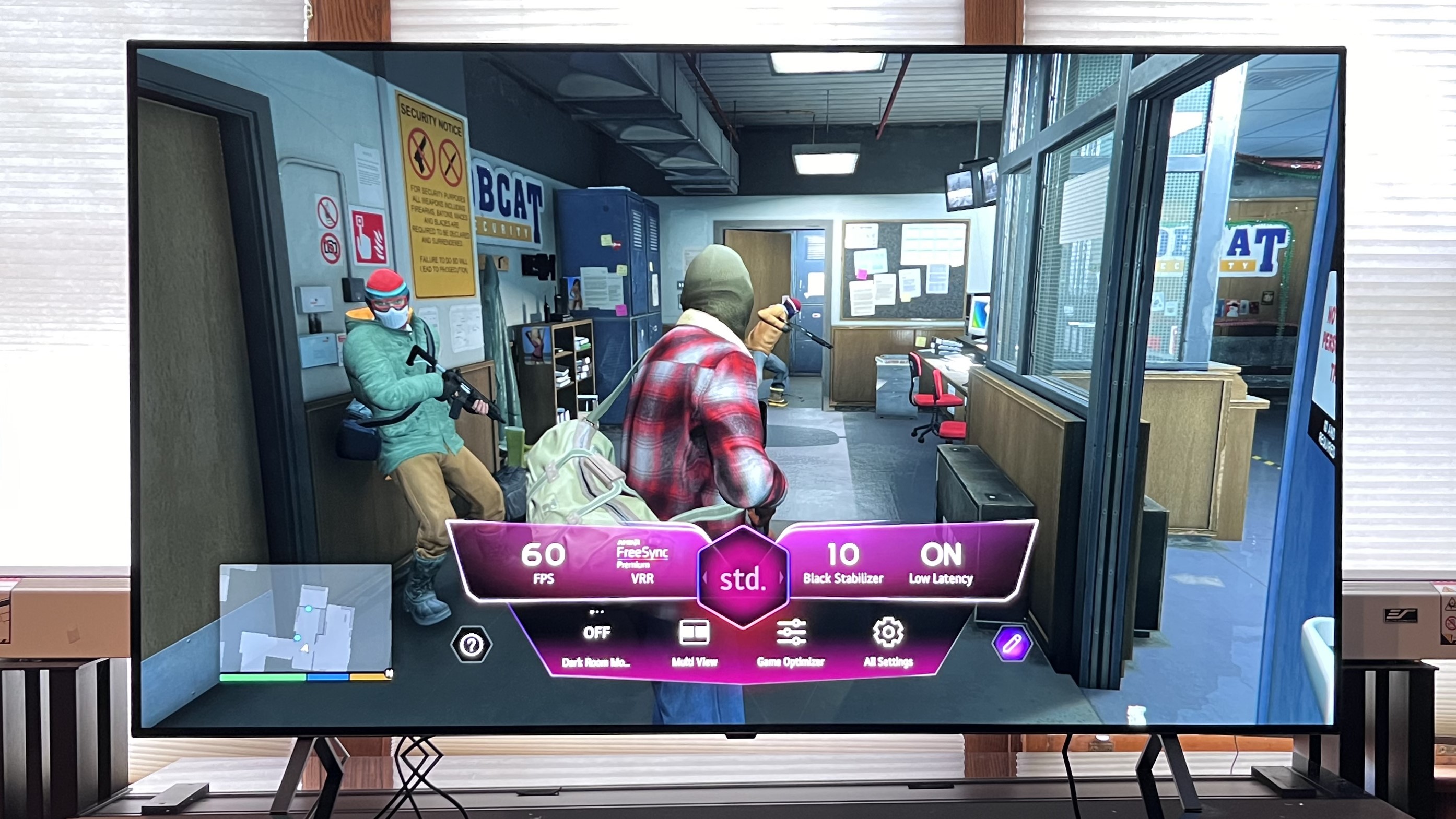

The LG C5 is a great choice if you want a gaming TV with full support for 4K 144Hz, VRR (AMD FreeSync Premium and Nvidia G-Sync), HGiG, Dolby Vision gaming and ALLM across its four HDMI 2.1 ports. Its Game Optimizer mode lets you fine-tune settings, while the Game Quick Card provides access to cloud gaming services, like Amazon Luna and Nvidia GeForce Now. Input lag measures an impressively low 9.2ms, and gameplay feels smooth and responsive with no tearing and blurring. Combined with the C5’s vibrant picture quality and deep contrast, it’s one of the best OLED TVs you can buy for gaming.

The LG C5 is a feature-packed OLED TV that offers premium performance at a mid-range price, making it one of the best all-round options for most people for movies and gaming. However, at launch, the 65-inch model costs $2,699.99 / £2,699.99. While the C4, which is still available, can now be found for $1,499.99 / £1,499.99, which is a big difference given how similar the two sets are. Yes, the C5 adds the brightness boost and new AI features, but it isn’t a major leap forward. Having said that, prices are likely to fall, and once the C4 disappears, the C5 will become even more of a clear go-to OLED.

The best budget OLED TV

Specifications

Reasons to buy

Reasons to avoid

1 minute summary: If you're looking for a cheaper way to get a 2024 OLED TV, then the LG B4 is for you. Although it's price isn't much less than the step-up LG C4, it's still cheaper, with further discounts likely to come. The B4 may be the entry-level OLED in LG's 2024 lineup, but I feel it outperforms its price, delivering a rich, colorful, accurate picture with plenty of detail. When I tested the B4, it proved to be a fantastic performer for movies, but also an accomplished gaming TV, with its four HDMI 2.1 ports supporting many features found in the best gaming TVs such as 4K, 144Hz, Dolby Vision gaming, VRR and more. I found its during testing that its sound isn't the strongest, with limited bass and average virtual surround reproduction, and its picture brightness pales compared to more premium OLED TVs, but the B4 is still an excellent entry-level set.

Reasons to buy

✅ You want an OLED on a budget: The B4 is cheaper than any other 2024 OLED TV on the market and mostly covers all the bases.

✅ You want a cheaper OLED for gaming: The B4 is an excellent gaming TV, with four HMDI 2.1 ports supporting 4K, 144Hz, VRR and more.

✅ You want a detailed picture: The LG B4's crisp detail, rich contrast and bold colors suggest a more premium OLED.

Reasons to avoid

❌ You want great sound: The B4's built-in sound doesn't match the quality of its picture, with limited bass and Dolby Atmos effects.

❌ You want the brightest OLED: Compared with step-up OLED models, the B4's brightness is average, peaking at 656 nits.

❌ You need full HDR support: The B4 supports Dolby Vision HDR, but not HDR10+.

In-depth analysis

The B4's picture impressed during our testing, with its deep black levels, strong contrast and vibrant colors in particular standing out. In our review, we praised the B4's "exceptional shadow detail" and its Dolby Vision Filmmaker Mode, which provided an accurate picture with ease. We did find that its lower brightness made its picture less dynamic than what you'll find in step-up OLEDs such as the LG C4, but the B4's picture is still very good, especially for an OLED at this price.

The B4's sound is average and while it does the job, it won't beat TVs like the Sony Bravia 8 anytime soon. While it delivers clear dialogue and has a good balance, its bass is limited and virtual surround sound effects lack impact. At higher volumes, it can even sound "thin and edgy" as we said in our review. For casual viewing, the B4's sound will most likely be fine, but if you're looking for a more cinematic experience, you'll want to add a soundbar.

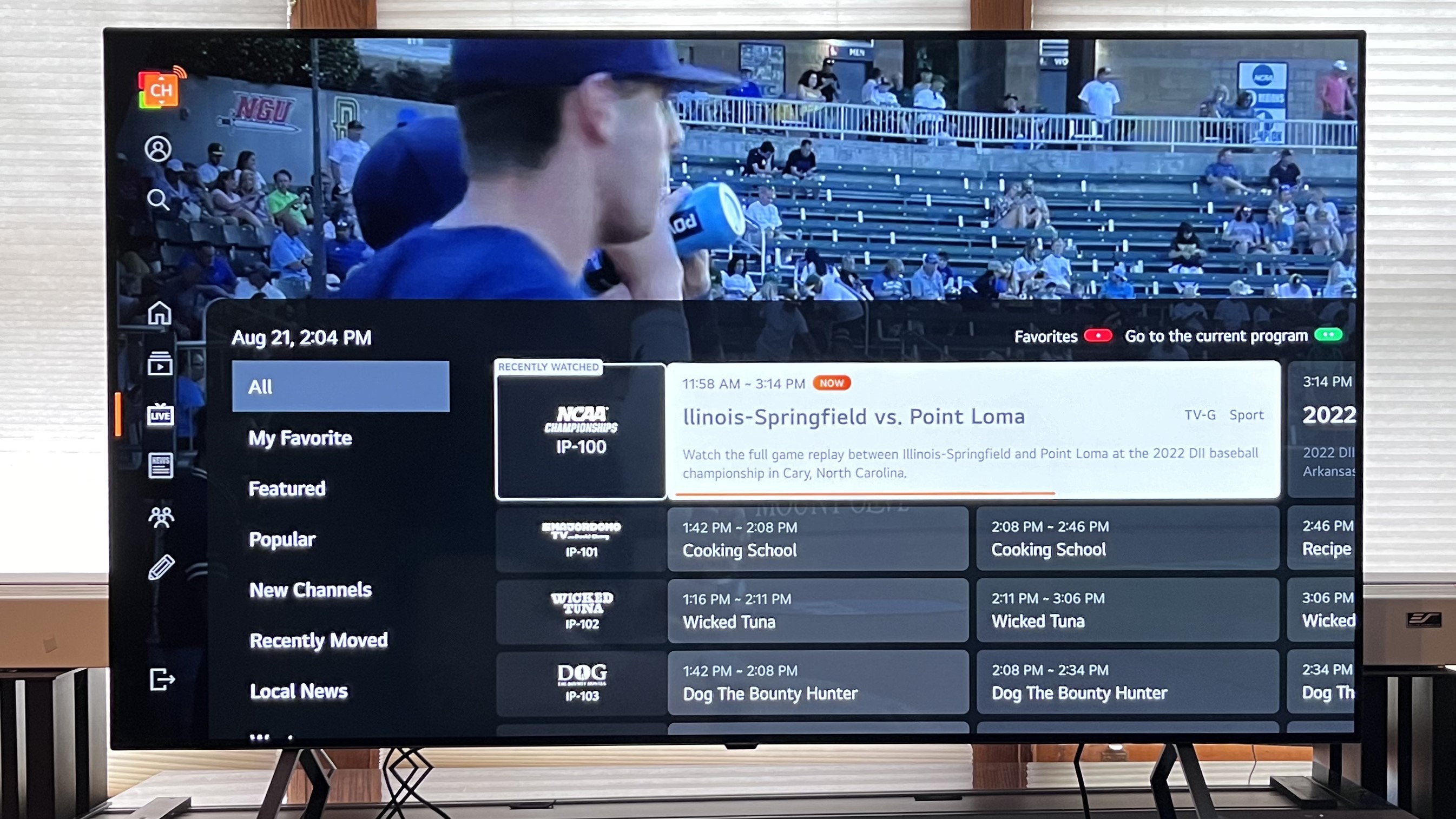

The B4 uses LG's own smart TV platform, webOS, and it's easily one of the best smart interfaces on the market. Quick Cards organize apps into easy to navigate categories and a Quick Menu, which we praised in our review, means useful settings can be adjusted easily without moving away from what's on screen. There is a large banner ad at the top of the home page, but this is becoming commonplace on smart TV platforms and is really the only criticism we have of the user-friendly webOS.

With four HDMI 2.1 ports supporting 4K 144Hz, Dolby Vision gaming, VRR (including AMD FreeSync Premium and Nvidia GSync), HGiG, ALLM and Dolby Vision gaming, the B4 has things more than covered when it comes to gaming. Its Game Optimizer is a useful feature that allows for easy adjustments to gaming settings and there's also cloud gaming app support. A 9.1ms input lag time (with Boost Mode activated) means the B4 delivers exceptional gaming performance and combined with the features listed above, the B4 comes out as a superb gaming OLED with a cheaper price tag.

The 65-inch B4 costs roughly $1,499 / £1,699 / AU$2,795. When compared to the $1,599/ £1,899 / AU$3,495 you'll pay for the LG C4, which provides higher brightness and a performance boost thanks to a faster processor, the B4 doesn't offer the greatest value overall. Still, it is a well-featured and high quality OLED TV that more than justifies its price.

LG B4 test results

The best premium OLED TV

Specifications

Reasons to buy

Reasons to avoid

1-minute summary: The LG G5 is the company's flagship OLED for 2025, and when I tested it, with its next-gen OLED panel, I could barely have been more impressed. Not only does this new panel bring spectacular color and contrast, but high brightness levels I didn't though would be possible on OLED a few years ago. Not only does it bring incredible picture quality, but it also comes loaded with the full suite of features I've come to expect from LG's OLEDs in both gaming and smart-based applications. I also found that the new AI-based tools in LG's latest smart TV platform, webOS 25, should give some users real help when navigating their new OLED TV. While it may be a pricier option than its step-down counterpart, the LG C5, I said in my review it still serves as "a best-in-class OLED TV option for 2025". It's easily the premium OLED to beat this year.

Read our full LG G5 review

Reasons to buy

✅ You want an OLED fit for all rooms: With higher fullscreen brightness levels and a new Filmmaker Ambient Light Mode, the G5 is ideal for all viewing situations.

✅ You want a TV for wall-mounting: With a slim-fit, wall-hugging design, the G5 will look perfect on your wall.

✅ You want a premium OLED for gaming: 4K, 165Hz, AMD FreeSync Premium and Nvidia G-Sync and a low 9.1ms input lag make the G5 one of the best gaming TVs around.

Reasons to avoid

❌ You want HDR10+ support: While it supports Dolby Vision, the G5 does not support HDR10+, which is used on some 4K Blu-rays and streaming services.

❌ You don't want to use a soundbar: The G5's built-in speakers are more than adequate, but don't match the level of its picture quality. It deserves a soundbar or speaker system.

❌ You want to save money: The step-down LG C5 doesn't deliver the same brightness or color depth, but it's significantly cheaper while delivering basically the same features.

In-depth analysis

The LG G5 introduces a new OLED panel called Primary Tandem RGB or 'four-stack', that delivers incredible brightness and amazing color and contrast. Now holding the distinction of the brightest OLED we've tested so far (it hit 2,268 nits in Filmmaker Mode), the G5 is superb in all viewing conditions with no need to adjust lighting. As we pointed out in our review "contrast, color saturation, and shadow detail all held up nicely even with my room’s overhead lighting on". A new Filmmaker Ambient Light Mode also effectively adjust gamma to suit your room's lighting conditions, meaning you never need to alter your settings. It also delivers fantastic motion for both sports and movies.

The G5's built-in 4.2 channel speaker system delivers clear speech and effective positioning of spatial sound effects, especially when using the AI Sound Pro mode. A new Sound wizard also allows you to create your own sound profile (in a similar vein to the TV's picture Wizard) which could be useful for some users. While the G5's sound is perfectly good, it deserves a robust Dolby Atmos soundbar to match its picture prowess.

Already one of the best smart TV platforms on offer, webOS 25 introduces new AI-based tools such as AI Search and AI Concierge that make browsing for and finding recommended movies and TV shows a breeze. Its Quick Card and Quick Menu remain useful staples of the webOS interface that make navigation user-friendly and easy. Plus, it runs smoothly with fast, lag-free performance.

As we said in our review "LG TVs have fantastic gaming credentials" and the G5 is no different. Four HDMI 2.1 ports all support 4K, 165Hz, VRR (AMD FreeSync Premium and Nvidia G-Sync), HGiG and Dolby Vision gaming, plus it boasts an ultra-low 9.1 ms input lag time when Boost mode in the Game Optimizer menu is activated. Its Game Quick Card also has access to a wealth of cloud based gaming portals such as Luna and Nvidia GeForce Now. When it comes to gaming TVs, it doesn't get better than the G5.

The G5 is a premium priced TV, but it delivers premium features and performance. That being said, the step-down LG C5 delivers a lot similar features and excellent performance for a lower cost and the G5 is priced higher than some of its rivals, including the Samsung S95F at launch. Still, given what the G5 does deliver, its pricing isn't surprising or unfair.

LG G5 test results

The best OLED TV for sound

Specifications

Reasons to buy

Reasons to avoid

1-minute summary: Panasonic’s new flagship OLED, the Z95B, is a worthy successor to last year’s Z95A. It introduces a new Primary RGB Tandem panel that pushes brightness while delivering richer, more natural color detail. In our testing, it hit an impressive 2,107 nits. But Panasonic has made a commitment to accuracy over brightness. The result is that movies look refined, subtle and true-to-life, rather than simply boosted. But the real story here is sound. The Z95B takes a big step forward with audio. Its 360 Soundscape Pro system, tuned by Technics, has been upgraded with new drivers and a refined speaker layout. The result is one of the best built-in sound systems you’ll find on any TV. It’s powerful, immersive and clear enough that you can even comfortably skip buying a soundbar. That alone gives the Z95B excellent value compared to its OLED rivals.

Read our full Panasonic Z95B review

Reasons to buy

✅ You want the ultimate movie night TV: The Z95B’s sharp, colorful and accurate picture makes Blu-rays and streaming films look incredible.

✅ You don’t want to clutter your living room with a soundbar: Its built-in 5.1.2-channel speaker system delivers big, immersive sound that’s good enough to stand on its own.

Reasons to avoid

❌ You prefer watching with the lights on: The picture is good in all scenarios, but it's at its best in dim rooms, and the anti-glare screen isn’t the strongest for bright, sunlit spaces.

❌ You dislike fiddling with settings: This TV has a long list of advanced picture and sound options, and while you can ignore them, some fine-tuning helps unlock its best performance.

In-depth analysis

Panasonic has introduced a new 'four-stack' OLED panel design in the Z95B, with separate red and green layers sandwiched between dual blue layers. This allows for a much brighter image than past models while keeping color richness intact. Our tests measured peak HDR brightness at 2,107 nits – impressive by OLED standards. But unlike rivals chasing sheer brightness, Panasonic’s focus here is accuracy. The Z95B delivers a natural, finely balanced image with subtle gradations and detail. Skin tones and textures look especially lifelike. There’s also an advanced cooling system to help the panel maintain peak brightness during demanding HDR scenes. In its most accurate presets (Filmmaker Mode, True Cinema, Cinema), it doesn’t reach the same dazzling brightness as some competitors. But what you gain is a consistent, refined picture.

The Z95B retains the 5.1.2-channel 360 Soundscape Pro speaker system from the Z95A, but Panasonic has improved the driver quality and tweaked the layout too. The result is even better, spacious, powerful and immersive sound. In fact, we’d call this one of the best built-in TV sound systems available today. Dialogue is clear, effects have impact and there’s enough scale to rival mid-range soundbars. A handy “Sound Focus” feature ensures dialogue stays sharp even when you’re sitting off to the side. We rarely say this, but the Z95B is strong enough sonically that you could skip an external soundbar and still feel very satisfied. That makes it exceptional value in the premium TV market.

The Z95B runs Amazon’s Fire TV platform. While it isn’t the slickest or most elegant interface in our opinion, it’s reliable, offers a wide spread of apps and integrates well with Alexa and Prime Video. Navigation is quick, and performance felt solid across apps and menus. It’s not our favorite smart platform compared to LG’s webOS or Samsung’s Tizen, but it covers the essentials well and many will appreciate its familiarity. Gamers also benefit from Fire TV’s support for cloud gaming apps.

The Z95B is well-equipped for gaming. There’s support for 4K at 144Hz, Dolby Vision gaming, and VRR, including AMD FreeSync Premium and Nvidia G-Sync. Input lag is low, and the picture retains the same accuracy advantages seen in movies. The main limitation is connectivity. With only two HDMI 2.1 ports, rather than the four found on some competitors, you’ll need to prioritize which devices get full-featured connections. But the Z95B’s strong built-in sound system reduces the need for a soundbar, making this compromise less restrictive than usual.

Panasonic OLED TVs are usually priced higher than the competition, but the Z95B launched at the same level as key rivals. Add in the fact that discounts are already appearing and this flagship is looking like excellent value. Factor in the built-in 5.1.2-channel audio, which genuinely removes the need for a separate soundbar, and the Z95B stands out as one of the smartest buys in the premium OLED space right now.

Panasonic Z95B test results

The best OLED TV for bright rooms

Specifications

Reasons to buy

Reasons to avoid

1-minute summary: The Samsung S95F has the reflection-beating matte screen of its predecessor, the S95D, but improves on it by maintaining more accurate black levels even in bright conditions. It also delivers spectacular colors and realistic textures. The S95F is a gamer's dream, with 4K 165Hz, VRR (AMD FreeSync Premium and Nvidia G-Sync), ALLM and HDR10+ gaming support across four HDMI 2.1 ports and is a good-looking TV, with a razor-thin profile. While its sound could be better and there is still some black crush in darker scenes, the S95F is still undeniably one of 2025's best TVs.

Read our full Samsung S95F review

Reasons to buy

✅ You want an OLED fit for all rooms: With OLED Glare Free anti-reflection tech, the S95F's impeccable picture can be viewed in the brightest of rooms.

✅ You want the QD-OLED experience: Contrast, brightness and color are all fantastic on the S95F, proving the advantages of its QD-OLED display panel.

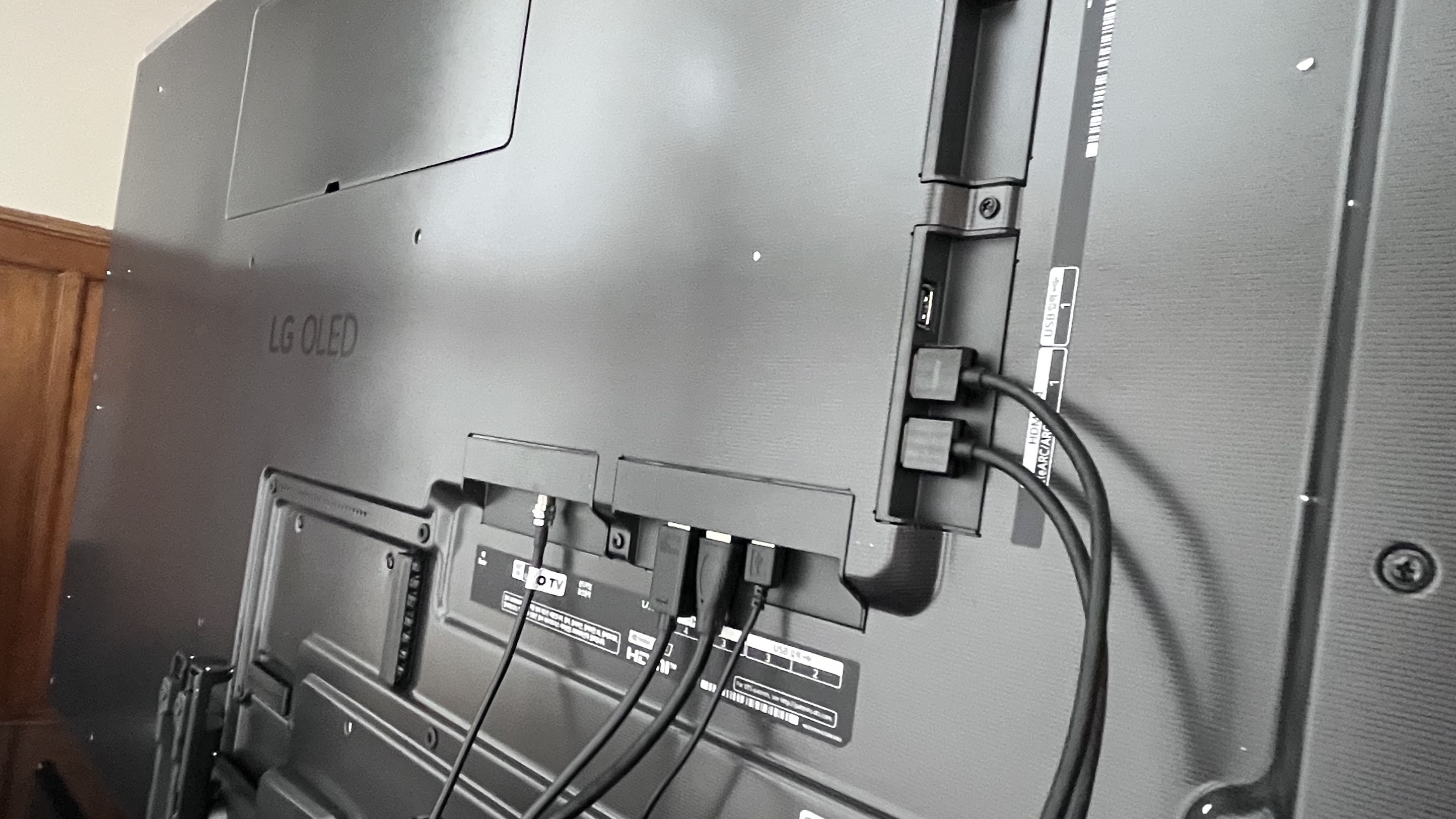

✅ You want an OLED that looks premium: A trim profile, razor-thin depth, and an external connections box to keep things neat make the S95F one of the best-looking TVs around.

Reasons to avoid

❌ You want full HDR support: Despite covering nearly all the bases, the S95D does not support Dolby Vision HDR.

❌ You want the absolute best black levels: The S95F's anti-reflection screen is useful, but it does compromise on black levels, which look raised compared to the competition.

❌ You're on a budget: Elite performance does come with an elite price tag, and the S95F sits near the top end of the OLED market.

In-depth analysis

I described the S95F as " a sight to behold even compared to the best OLED TVS" in my review, thanks to its stunning brightness levels, gorgeous, vibrant colors and solid contrast. The real star of the show is its OLED Glare Free 2.0 screen, which eliminates pesky mirror-like reflections even in the brightest of rooms. Its motion handling is also responsive with a bit of tweaking, making it great for viewing sports. While there are instances of black crush, the S95F's picture is staggeringly good and it's easily one of the best I've seen in 2025.

Tizen has never been the best smart TV platform, but Tizen 9.0, the 2025 version, is the best one yet. With a useful quick menu, access to every major app and hubs for app organisation – Game, Home, Daily+ and Ambient – Tizen is now in a better place. Yes, some settings are still buried in deep menus and are a pain to access, but that is my only real gripe with this now-great smart TV system.

The S95F's built-in sound delivers punchy bass, effective placement and tracking of sound thanks to Samsung's Object Tracking Sound+ feature, and speech is clear throughout. Where the S95F comes up short is in its narrow-feeling soundstage, which isn't as immersive as the sound on TVs from the likes of Sony and Panasonic. Some people will be pleased with the S95F's sound, but others may want a soundbar for a more cinematic experience.

Gaming is another area where the S95F shines. It's packed with gaming features, including 4K 165Hz, VRR with AMD FreeSync and Nvidia G-Sync, ALLM and HDR10+ gaming, along with four HDMI 2.1 ports. It also delivers an ultra-low 9.5ms input lag time as well as Samsung's Gaming Hub with cloud gaming options for those without a console. Picture-wise, the S95F benefits any game played on it. The S95F is a phenomenal gaming TV that gamers will love.

As always, judging a flagship OLED's value is tough. While the S95F more than delivers for the money with its features, picture quality and premium design, its price tag ($2,499 / £2,499 for the 55-inch model I tested) will outstretch most budgets. The S95F is an elite TV after all, so its hefty price tag is to be expected.

Samsung S95F test results

How to choose an OLED TV

How to choose the best OLED TV for you

• Most OLED TVs are premium: 4K, 120Hz, with four HDMI ports

• Brightness varies greatly and some have more HDMI 2.1 ports for gaming

• Samsung OLED TVs use HDR10+, most other OLED TVs have Dolby Vision

OLED TVs tend to be premium TVs, which means you're getting a certain level of features in almost all of them – they're all 4K, they're mostly 120Hz for gaming, for example, and they tend to all have four HDMI ports, and premium smart TV software.

But they're absolutely not all the same. Some are much brighter than others (around twice as bright, in some cases), some have more HDMI 2.1 ports for next-gen gaming, some have better sound systems, and they don't all come in the same size options.

It's important to consider what size TV is best for you, and to do that you'll literally need to measure the space you have to work with. Remember a TV that fills every available scrap of space in your living room might sound like a great idea, but you'll need to consider viewing angles, screen brightness and whether you'll be able to sit a decent distance from the TV to fully appreciate it. The LG C4 has the widest range of sizes of any TV we feature, so if you need something smaller, that's a great place to start.

When it comes to HDR support, we recommend mostly that people choose TVs with Dolby Vision, because it's the most commonly used advanced HDR format on the best streaming services. Samsung TVs only use HDR10+, which is similar technology, but not as well supported. It's not a dealbreaker that Samsung's TVs don't support Dolby Vision, but as you'll see in our list, we prefer sets that include it.

What new OLED TVs are coming soon?

At the start of the year, at the big CES 2025 technology show, we got our first look at the new OLED TVs coming during 2025.

LG has released the LG G5, which has taken a top-level spot on this list as our choice for 'Best premium OLED.' We've also reviewed the mid-range LG C5 OLED, though the LG C4 remains our pick as the 'Best for most people' due to its ongoing availability and excellent value. The LG B5 budget TV should comes a little later, though this year the B5 is only coming in two sizes, sadly.

The Samsung S95F and has since been added to this list as the best OLED for bright rooms . This TV also comes in an 83-inch model for the first time – though that size will use a new-gen W-OLED panel (the same as the LG G5) instead of the QD-OLED panel used for the 55-inch, 65-inch and 75-inch sizes. Samsung also announced the S90F mid-range OLED TV, in sizes from 42 inches to 83 inches. Finally Samsung will have a cheaper S85F OLED TV option, which is expected to be less bright.

Sansui has announced that it will have a budget range of OLED TVs from 55 to 77 inches in the US, which we expect will start from about $800 based on last year's models – that's massively cheaper than the equivalent from LG.

Panasonic announced that it will launch a new range of OLEDs, led by the flagship Panasonic Z95B, a model that has since been added to this list as the best for sound option

Hisense will have some OLED TV options in some countries, but we're waiting on confirmation of what those TVs will be in terms of size and specs.

Sony released the new Sony Bravia 8 II OLED, and Philips will likely announce new OLED TVs for the UK and Europe, also closer to spring.

How much do OLED TVs cost?

• Entry-level OLED TVs tend to cost from $1,000 / £900 / AU$1,500

• You'll pay twice as much for mid-tier OLED TVs and triple for high-end sets

• Sales events like Black Friday and Prime Day are a great time to buy an OLED TV

The cost of OLED TVs varies hugely depending on what technologies are thrown in with an OLED panel, such as the resolution, processor, build quality, built-in speakers, and more. But suffice to say that entry-level models sit around (or, more recently, just under) the $1,000 / £900 / AU$1,500 mark.

More mid-tier OLEDs at larger sizes (65 inches and above) can double that figure, or triple it when you're looking at the cutting-edge high-end panels. You might also notice that you don't get that much of a lower price with the smaller 42-inch sizes of OLED TV – that's because making them so small relies on relatively new tech, so they're not quite such good value per inch.

Sales periods such as Prime Day or Black Friday tend to include lots of discounts on OLED TV models, though – especially from LG and Samsung.

Should I buy OLED or QLED?

• Samsung TVs often use its competing QLED tech rather than OLED

• QLED generally has better brightness than OLED

• Mini LED TVs have OLED-rivalling or beating contrast

OLED isn't the only option for savvy TV buyers. Samsung's competing QLED televisions outperform for brightness, while the introduction of Mini LED backlights has only improved peak light output and overall contrast – the areas that OLED generally has the upper hand with, thanks to its per-pixel brightness control.

It's a tighter race than ever, then, though it's worth assessing secondary characteristics for OLED and QLED screens. An OLED with a cheap processor may cause more artefacts and video noise, while a QLED with edge-lighting won't get the true benefit of its enhanced color and contrast. Format or feature support can be crucial if you're hooking up your TV to a PC, a games console, or a 4K Blu-ray player too.

What is the lifespan of an OLED TV?

According to LG Display, the makers of the OLED panels that go into every OLED TV on the list - around 100,000 hours. For most folks that's about 10 years of TV watching and far exceeds the 40,000 to 60,000-hour lifespans of most LED-LCD TVs. That said, OLED TVs can experience something called burn-in when a static image is left on the screen for prolonged periods of time - so be sure to change the channel every few days.

Best OLED TV competitors: what else is out there?

OLED is, for many, the premium TV tech of the moment. Though once weighed down by inaccessible price points, a flurry of cheaper mid-range OLEDs and smaller panel sizes has helped bring OLED closer to the mass market.

Samsung and Sony's current TV lineups include QD-OLED hybrids (they combine OLED panels with quantum dot tech, utilising the self-emissive properties of the former and color enhancements of the latter) – we have a separate guide to whether you should buy a Samsung OLED TV, if you want to read more about them.

For those with cash to splash, you'll be choosing between a high-end OLED TV and Micro LED – a self-emissive panel technology that Samsung has leant into in recent times, but which has proved difficult to offer either affordably or at mainstream sizing (88-inch is the smallest we've heard about so far, as of 2024).

It's a more complicated picture than simply OLED, then, though for deep blacks and true-to-life color – at a size you can actually get into the average living room – OLED may still be the best choice.

Is burn-in a problem in OLED TVs?

• Burn-in has traditionally been a problem on OLED TVs

• Most OLED TVs now have ways to prevent burn-in, including Auto Brightness Limiting (ABL)

• These days, burn-in is not a big problem or something to worry about

Burn-in, also known as screen burn or permanent image retention, is a visual artefact that sometimes appears when a TV has shown the same thing in the same place for a long time. It definitely happens on some OLED TVs, but manufacturers have come up with lots of ways to minimise the likelihood of it happening to yours.

There are three main ways in which OLED TVs can minimise the likelihood of burn-in. They can use image analysis to identify static images – TV channel logos, for example – and subtly dim them. They can gently shift the image around by a few pixels, something that your OLED probably does already without you noticing it.

And there's a more brute-force approach, where the TV automatically dulls the brightness of the whole display when it detects a bright and potentially burn-in item. That latter one is the least popular because if it isn't implemented well it can be quite dramatic and quite annoying. More modern TVs with this tech, known as ABL (Auto Brightness Limiting) are much more subtle about it than older ones.

Last but not least, you can take the DIY route. The default modes such as Vivid Mode on some TVs can be ridiculously bright, so changing them or using less blazing settings will make your eyes happy and reduce the risk of burn-in even further.

Ultimately burn-in is all about heat, hence the name. And the best way to reduce the risk of it and perhaps eliminate it altogether is to manage heat better in OLED TVs. And manufactures are doing just that. You'll find clever heatsink technology and heat dissipation design in OLEDs from Panasonic, LG, Sony and more.

We're not saying burn-in doesn't exist. It does. But the advances in OLED TV tech in recent years means it's much less of an issue than it was in early OLEDs, and for most of us it's something we don't really need to worry about too much.

Which OLED TVs are best for gaming?

• OLED TVs usually have a fast 120Hz or 144Hz refresh rate, which is great for gaming

• The Xbox Series X's Dolby Vision format won't work with Samsung TVs

• Look for HDMI 2.1 ports – ideally four – for ultimate gaming performance

Arguably, all OLED TVs are ideal for gaming as they typically have a fast, 120Hz or higher refresh rate and pixel-level brightness control that helps fast-motion images look solid. Even so, there are differences between the various OLED TVs in this guide that can make them better suited for different gaming scenarios.

High dynamic range support varies among the different TV brands, and that can have an impact on gaming. Samsung TVs, for instance, support the HDR10+ format, but not Dolby Vision. So, if you’re using an Xbox Series X console, you won’t be able to take advantage of its Dolby Vision gaming capabilities when playing on a Samsung TV. LG TVs, in contrast, do have Dolby Vision HDR support, but not the competing HDR10+ format. That’s not as much as an issue for gaming, however, as the availability of games with HDR10+ is very limited compared to Dolby Vision. Panasonic TVs support both the Dolby Vision and HDR10+ formats.

If you’re looking for a maximum 4K 144Hz refresh rate for PC gaming, you’ll find broad support for that feature among the TVs in this guide. In fact, the only TV that doesn’t offer 4K 144Hz support is the LG B4, which maxes out at 4K 120Hz.

The Samsung and LG TVs in this guide each provide four HDMI 2.1 ports with 4K 120Hz pass-through. Having four HDMI ports on a TV used for gaming is important because it allows you to connect both PS5 and Xbox One X gaming consoles and take advantage of their high refresh rate capability while also connecting a soundbar to the TV. Like many other TVs, the Panasonic TV in our guide maxes out at two HDMI 2.1 ports. That’s not so much of an issue in this case, however, since the Panasonic’s excellent built-in speaker system is powerful enough that you don’t necessarily need a soundbar.

How bright are OLED TVs compared to other TVs?

• Brightness used to be a problem for OLED TVs

• New tech such as QD-OLED and Micro Lens Array has vastly improved brightness

• Some of the latest sets also have anti-glare screen coatings

OLED TVs in the past lagged behind QLED TVs with regular LED and mini-LED backlights when it came to brightness. The most recent crop of high-end OLED TVs has changed the game, however, by using new technologies such as QD-OLED (a Samsung-developed tech that combines an OLED display panel with quantum dots which is used in specific Samsung and Sony OLED TVs) and Micro Lens Array (an LG-developed tech combining a layer of microscopic lens elements with an OLED panel that’s used on specific OLED TVs from LG and other brands, including Panasonic). LG has also introduced the Primary Tandem RGB (four-stack) panel to the mix, adding even more brightness and more accurate black levels and color to deliver brightness like we've never seen in an OLED before.

These new technologies have now made OLED competitive on the brightness front, with new models such as the Samsung S95D, LG G5 and even the LG G4 delivering peak brightness levels that even exceed some mini-LED TVs, which are typically the brightness champs. The LG G5 and G4 and especially the Samsung S95D also use anti-glare screen coatings, which, combined with the TV’s high brightness levels, make them a reasonable option for viewing in well-lit living rooms.

How we test the best OLED TVs

• We run a suite of subjective and objective tests when reviewing TVs

• We use specialized equipment such as colorimeters and test pattern generators

• We test gaming features, upscaling, viewing angles and use different AV sources

When testing the best OLED TVs, we use the same criteria that we consider in all of our TV reviews, which focuses on picture quality, audio quality, smart TV platform, design, gaming features and value for money. Our testing is not only made up of subjective opinions about each of criteria, but also on objective measurements taken using specialized equipment – you can read our full guide to how we test TVs at TechRadar, or read on for a summary.

Using different AV sources, including broadcast, streaming and Blu-ray, we’ll run in every TV whilst cycling through its picture preset modes, such as Sport, Movie and Standard, to determine which settings are the most accurate for different types of media. We do this to determine what the best settings are for watching movies and TV shows or a sports match for example. Once we have established which picture modes are best suited for different types of content, we then analyze aspects of the display such as its colors, contrast, black levels and more using reference scenes we have specifically chosen to best evaluate these.

When testing an OLED’s picture quality, we’re looking for deep black levels and contrast, which should be better than many other TVs on the market thanks to the screen’s ability to dim individual pixels over local dimming found in LCD TVs – often this is determined by zones and the backlight’s ability. We’ll also look at the color’s vibrancy and punchiness compared to textures and details, particularly sharpness and true-to-life accuracy.

Using lower-resolution sources such as broadcast and DVD, we’ll also test a TV’s upscaling, looking to see how effectively that TV’s processing can enhance lower-res images to be displayed on a larger, 4K screen. During these tests, we also consider the viewing angle from off-center seats, which – again with the OLED panel’s ability to self-dim – should maintain strong contrast levels and picture quality even from the most awkward of viewing positions.

After these subjective tests, we then take specialized equipment — a colorimeter, test pattern generator and Portrait Displays’ Calman calibration software – to perform objective tests and record the results, taking measurements of brightness, color and grayscale accuracy, gamut and more.

The first test we usually do is of the TV’s brightness. Using different sized white window patterns, we measure the the TV’s peak brightness on windows including 10%, which will show the maximum brightness we can expect from the TV itself, and 100% to test full screen brightness, which will demonstrate how the TV can handle consistent levels of brightness across the whole screen (this is key when viewing sports). Full screen brightness also gives an idea of how well a TV will manage reflections.

OLED TVs have often been known to offer lower levels of brightness when compared to QLED and mini-LED. But in recent years, the introduction of OLED EX panels and micro-lens-array (MLA) tech means we expect higher peak brightness levels, but still lower full screen brightness when compared to other LCD panels. We use light controlled environments when testing brightness to make sure any other light sources, environmental or otherwise, does not affect results.

We also test color color reproduction in both SDR and HDR to compare its accuracy when displaying different source materials and the maximum color gamut it can show on screen. We do the same for grayscale as well, testing just how accurately a TV displays gray tones from black to white. With OLED TVs, we expect color accuracy to be among the best in the TV market, along with grayscale.

Gaming is another important aspect of TVs nowadays, so we make sure to test a TV’s gaming performance by analyzing response time, graphics and latency — all of which are areas OLED TVs often excel at. We also look out for features such as a Game Mode (for adjusting a TV’s settings to the most optimum for gaming), 4K 120Hz, VRR and more. We measure response time by using a Leo Bodnar 4K HDMI input lag tester to see what latency is added by a TV’s processing.

We always aim to keep our testing as consistent as possible, but it’s important to note that some of our writers’ setups and testing environments do vary. We do, however, make sure that all tests conducted use the same criteria between all of our writers, also making sure that the equipment is similar enough to achieve the same level of accuracy.

More OLED TVs we've tested

Why is the Samsung S90F series not in this guide?

The Samsung S90F series OLED TV received a five-star rating in our Samsung S90F review, but isn’t included in this guide. The main reason for this is that the 65-inch model Samsung sent us for review features a QD-OLED display panel, while other screen sizes in the S90F series are subject to a ‘panel lottery’ where either a QD-OLED or a regular W-OLED display panel may be used in the TV.

This means that our Samsung S90F ratings apply to the 65-inch model and don’t necessarily extend to other screen sizes in the S90F series. Our review praised the S90F for its impressive brightness, richer color than its Samsung S90D predecessor, and its crisp 4K upscaling of HD sources. The only areas where we found its picture lacking were a tendency to crush shadow detail in some presets, and a slight gray cast to blacks when watched in rooms with bright ambient lighting – a limitation you won’t find on OLED TVs with higher peak light output, such as the LG G5 (included in this guide as 'The best premium OLED.'

Otherwise, S90F series TVs are an excellent option for gaming, with 4K 144Hz support across all four HDMI 2.1 ports, AMD Freesync Premium Pro format and Nvidia G-Sync, Samsung’s Gaming Hub for cloud-based gaming, and an ultra-low 9.2ms measured input lag. The 65S90F model we tested is also a great value for a QD-OLED TV, coming in around £700 / $800 cheaper than the 65-inch version of Samsung’s S95F flagship OLED for 2025.

Other OLED TVs that we've tested

LG G4: One of LG's flagship OLEDs for 2024, the LG G4 delivers superb picture quality and comes with all the features you'd need; both gaming and smart. It earned five out of five stars in our LG G4 review as it really is the complete package. It's not on our list as it's been replaced by its successor, the LG G5, which delivers everything the G4 does but with added brightness and even better picture quality. Don't get us wrong; the G4 is still a fantastic TV and if you can get a good deal on it, it's absolutely worth the investment!

LG C5: The successor to the #1 TV in this guide, the LG C4, the LG C5 continues the LG C-series legacy of delivering arguably the best picture, features and performance for its competitive price in the mid-range OLED market. Earning five out of five stars in our LG C5 review, the only reason it's not on this list is because the C4 is still available for far lower prices. The C5 isn't enough of an upgrade to warrant knocking off the C4 yet, but once the C4 is no longer available, the C5 is likely to take its place.

Sony Bravia 8: Sony's only 2024 OLED TV, the Bravia 8 impressed us during testing with its lifelike details and vivid colors, thanks to a brightness boost over its predecessor, the Sony A80L, that make HDR images pop. It's also a solid gaming TV with 'perfect for PS5' features and it has brilliant built-in sound. While it's a great TV, it doesn't hit the right price point like the LG C4, but if you want a more mid-range option with sound good enough to not need a soundbar, it's a very strong option, as our full Sony Bravia 8 review really digs into.

Panasonic Z85A: A mid-range OLED TV, the Panasonic Z85A still showcases the superb picture quality we've come to know from Panasonic's OLEDs. Plus, it delivers a good array of gaming features and solid built-in sound. Unfortunately, it has to contend with a crowded mid-range OLED TV market that's dominated by the LG C4, which offers a lot of the same plus points of the Z85A at a much cheaper price, though otherwise our Panasonic Z85A review is pretty glowing.

Philips OLED809: It's no secret that we here at TechRadar adore Philips' OLED TVs, mostly for their unique Ambilight feature; a series of lights around the frame of the TV that project bold colors around and onto the wall behind. The OLED809 delivers excellent picture quality for a mid-range OLED, but is slightly beaten on overall value by the LG C4 – it's also only available to our UK and European readers. Read our Philips OLED809 review if you like the idea of a TV that feels much bigger than it is, though.

Philips OLED909: This is a high-end TV, using the same elite panel as the LG G4, delivering stunningly bright and HDR-rich picture, aided by the Ambilight feature. The built-in Bowers & Wilkins sound system is also a nice addition, adding real meat compared to other built-in TV speakers, and replacing the need for a smaller soundbar. We think the Samsung S95D is a little more versatile and better value for most people, but it's an excellent TV, no question, as our full Philips OLED909 review digs into.

Philips OLED959: This is a truly elite TV, but puts itself in quite a niche bracket by coming in very specific sizing, and with a giant metal stand as part of the package. It's also pricier than the competition – and its 'upgraded' version of Philips' Ambilight tech was too busy for us, and doesn't actually feel like a higher-end version. Still, you get amazing image quality and top-tier built-in sound, so if you like the idea of a freestanding TV with awesome AV skills, it's well worth reading our Philips OLED959 review.

The latest updates to this best OLED TVs guide

October 24, 2025

Replaced the LG C4 with the newer LG C5 as our 'best for most people' pick, based on our recent testing.

August 27, 2025

Replaced the Panasonic Z95A with the brand's latest flagship OLED TV, the Panasonic Z95B, as our 'Best for sound' pick.

July 1, 2025

Replaced the Samsung S95D with the Samsung S95F due to the latter's higher brightness and improved black levels.

Read more updates…

June 3, 2025

Added 'Why is the Samsung S90F series not in this guide?' entry to 'More we've tested' section.

April 17, 2025

Added in Quick List with summary for each entry on this list. LG G5 replaced Samsung S95D as 'best premium OLED'. Samsung S95D became 'best OLED for bright rooms'. Removed LG G4 and 'best for wall-mounting' category, since the G5 covers that. Added more models to 'More OLEDs we've tested' section.

March 17, 2025

Added more information about our team in the introduction. Checked all products against our latest reviews, added more information to our list of other OLED TVs we've tested.

February 14, 2025

Added 'Which OLED TVs are best for gaming?' and 'How bright are OLED TVs compared to other TVs?' sections to FAQ.

January 15, 2025

Added information in the FAQs about the new OLED TVs arriving in 2025.

December 23, 2024

Removed the Samsung S90C due to stock levels. LG C4 became 'best OLED TV overall'. Updated Also Consider list with more OLED TVs we've tested that didn't quite make the list.

November 18, 2024

Replaced the Sony A80L with the Panasonic Z95A as 'best for sound.'

October 24, 2024

Replaced the LG G3 with the LG G4 as 'best for wall mounting'.

September 27, 2024

Replaced the LG B3 with the LG B4 as 'best budget OLED'.

August 2, 2024

Updated the format of this guide to offer more information about the merits of each TV's different strengths and weaknesses, with personal insight from our reviewers.

July 4 2024

Added 'Also consider' section with details on forthcoming new OLED TVs and carryover models in 2024.

June 7 2024

Swapped the LG C3 for the LG C4 as the #best for sizes'. The LG C3 is cheaper than the C4 after discounts, but the C4 has had several brightness and processing improvements that make it worth its price.

May 10 2024

Swapped Samsung S95C for Samsung S95D as the 'Best premium OLED', based on our review. The S95C is cheaper than the new model after price drops, but because it's still high-priced, and the S95D has the new anti-glare screen, we think the model is worth paying up for.

April 11 2024

Rewrote introduction and updated information throughout to ensure all advice is up-to-date.

March 14 2024

Added graphs with data from our testing to each TV's write-up, to make it easy to read and compare that information.

March 6 2024

Expanded the How We Test section with more in-depth information on how testing procedure works and what tests are carried out.

February 5 2024

Replaced the LG A2 with the LG B3 as 'best budget OLED TV.'

January 5 2023

Added the LG G3 as the 'best OLED TV for wall mounting' due to its high review score and special wall-mount bracket.

December 21 2023

Removed the Sony A95K and 'best for picture quality' category. Changed Samsung S95C from 'Brightest OLED' to 'Best premium OLED'.

November 21 2023

Checked all products against our latest reviews to ensure we're happy with the list (we are). Added a link to our Black Friday OLED TV guide.

October 19 2023

Updated the product lists to make the Samsung S90C our number one pick, reflecting our reviews. Added the LG B3 as the best cheaper gaming OLED.

September 21 2023

Added more buying advice for each model.

August 18 2023

Confirmed all links to ensure availability of models in list.

June 26 2023

Added this 'latest updates' section, to help readers see what recent changes have been made. Checked the products in the list against our latest reviews.

Sign up for breaking news, reviews, opinion, top tech deals, and more.

Matt is TechRadar's Managing Editor for Entertainment, meaning he's in charge of persuading our team of writers and reviewers to watch the latest TV shows and movies on gorgeous TVs and listen to fantastic speakers and headphones. It's a tough task, as you can imagine. Matt has over a decade of experience in tech publishing, and previously ran the TV & audio coverage for our colleagues at T3.com, and before that he edited T3 magazine. During his career, he's also contributed to places as varied as Creative Bloq, PC Gamer, PetsRadar, MacLife, and Edge. TV and movie nerdism is his speciality, and he goes to the cinema three times a week. He's always happy to explain the virtues of Dolby Vision over a drink, but he might need to use props, like he's explaining the offside rule.

- Al GriffinSenior Editor Home Entertainment, US

- James DavidsonTV Hardware Staff Writer, Home Entertainment