What's unique about Microsoft's Surface tablet Touch Cover?

We look at the technology behind the Surface tablet

With eyebrows raised following the decision to launch its own hardware, what's inside Microsoft's Surface tablet that makes it worth considering?

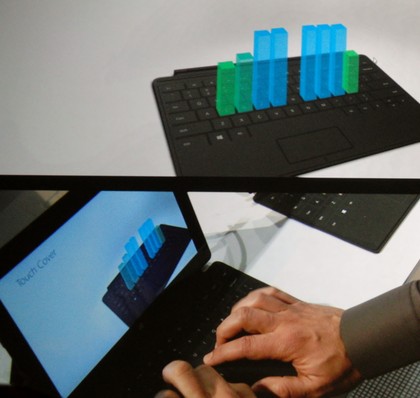

The technology inside the Touch Cover (one of the methods of adding keys to the standard tablet) first showed up in the multi-touch Sidewinder x4 gaming keyboard in 2010 – and that was based on a patent Microsoft has had since 2003, waiting for the right product to put it into.

- Hands on: Microsoft Surface tablet review

Stevie Bathiche manages the applied sciences group inside Microsoft hardware; he's worked on the table-sized Surface, the Kinect and prototype hardware for showing two people different images on the same screen.

He showed us the multi-touch sensors his team used to build the Sidewinder back at CES 2010 (at the time he hinted that the technology was "applicable to many different devices like mobile phones or anything that has buttons") and the same ultrathin, low-power super-fast film multi-touch digitiser is inside the Touch Cover and Type Cover keyboards for the new Surface tablet.

It's fast; the average keyboard matrix detects a keypress in 8 milliseconds; Microsoft says the Touch Cover is ten times faster at detection (which is better than the 2ms of the Sidewinder).

It's low power, because it doesn't start scanning the keys to see what you're pressing until you start hitting the keys hard enough to count as typing (and whenever the keyboard is folded away behind the screen it's off to save power).

It's also smart, in that it measures how hard you're typing ("it can detect grams of force," Bathiche notes) so if you just put your fingers on the 'home keys' (F and J, usually marked with bumps or ridges to help you get your fingers in the right place for touch typing), it doesn't treat that as typing.

Sign up for breaking news, reviews, opinion, top tech deals, and more.

And because these are multi-touch resistors, you can type as fast as you like and the keyboard won't get overloaded and block key presses the way mechanical buttons can.

That's more of a problem for gaming than typing email, but the Surface Pro's Core i5 will be fast enough for some reasonable gaming – although we're sure hardened gamers won't be using the Touch Cover as their main input method when getting their fix.

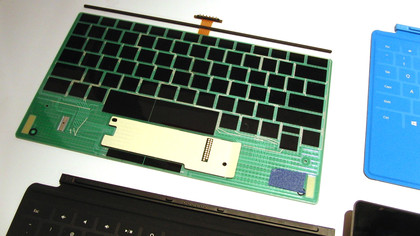

This multi-touch layer is how Microsoft can make the Touch Cover 3 millimetres thick; because the keys you're touching are resistors printed onto a film, there aren't any mechanical keys to take up space.

In the Sidewinder that plastic film is encased in a standard keyboard with backlights; inside the Touch Cover it's on a more traditional circuit board to give the cover enough rigidity for you to type on.

That also integrates the accelerometer that turns the Surface off when you close the cover and turns the keyboard off when you fold it back past 180 degrees.

The slightly thicker Type Cover keyboard does have physical keys that travel; they have the 1.5mm of movement that's common in laptops these days.

But they're not the usual mechanical keys; what they're hitting in the same touch resistor layout that's inside the Touch Cover, which is why even with mechanical keys, it's still pretty thin at just 6.8mm.

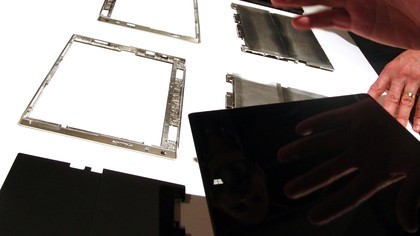

The Surface RT isn't much thicker than the Touch Cover, at just 9.3mm, but it's more rigid than many notebook screens that are thicker.

That's down the magnesium alloy which Microsoft moulds precisely; the thinnest parts of the Surface, like the hinge, are 0.77mm thick and Microsoft can mould the details of the magnesium parts down to 0.65mm.

The alloy frame around the screen and the back of the tablet are so thin and light you expect them to be flimsy, but they're rigid – we couldn't bend or twist them.

The different layers of the Surface are tightly packed, with far fewer layers in the touchscreen than usual; even on the Surface Pro which has a pen digitiser layer as well as touch.

The reason the digital ink looks so smooth is that the distance between the tip of the pen and the layer in the screen where you see the ink is only 0.7mm. "We've stacked up every part so tightly and cleanly in the product that if you stuck a piece of tape in the middle it would make a bulge," says Panos Panay, the general manager of Surface.

There are over 200 custom-made parts in Surface (including three that Microsoft designed for the hinge alone) and over 150 steps in the manufacturing process.

Microsoft is clearly viewing the Surface tablet as its chance to show its prowess as a manufacturer in another arena; as Bathiche puts it, "it's not just that it's a great idea; it's a great idea and we can build it."

Mary (Twitter, Google+, website) started her career at Future Publishing, saw the AOL meltdown first hand the first time around when she ran the AOL UK computing channel, and she's been a freelance tech writer for over a decade. She's used every version of Windows and Office released, and every smartphone too, but she's still looking for the perfect tablet. Yes, she really does have USB earrings.