These 3D-printed materials go from smooth to bumpy when you squeeze them

Exsqueeze me?

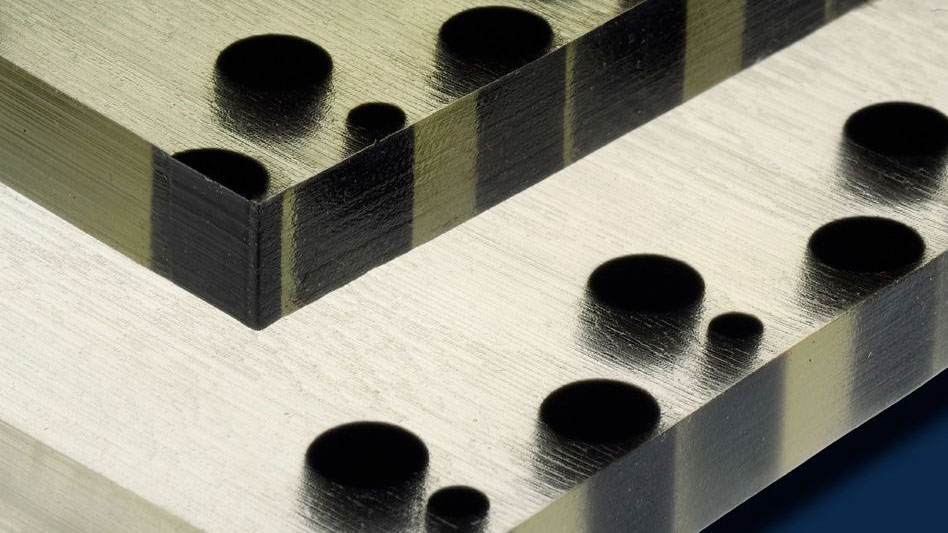

MIT's materials scientists have come up with a method for 3D-printing soft materials which go from smooth to bumpy when you squeeze them, forming ridges, bumps or even complex patterns that could guide fluids.

The material consists of two polymers that have differing stiffness levels. More rigid particles are buried below the surface of a softer material, and the spacing of the harder particles determines the patterns formed on the surface when squeezed.

"Depending on the arrangement of the particles, using the same amount of compression, you can get different surface topographies, including ridges and bumps, along the surface," said Mark Guttag, who's working on the research for his doctoral thesis. "There are no previous techniques that provide comparable flexibility for creating dynamically and locally tunable and reversible surface changes."

Bump 'n' Grind

This version of the materials uses squeezing to activate, but there's no reason why the same principles couldn't apply to other stimuli - electric charge, temperature or humidity. Elongated particles under the surface could even allow for asymmetrical surface textures - creating high friction in one direction but not in another.

The applications are widespread - surfaces like this could be useful in adaptive camouflage, limiting the buildup of organisms on the hulls of ships, or controlling motion and turbulence in pipelines. "It could be scaled to all different sizes, and the same principles should work," said Guttag.

Details of the discovery were published in the journal Advanced Functional Materials.

Sign up for breaking news, reviews, opinion, top tech deals, and more.