3D printed organ tech just took a giant leap forward

Floating printed organs - really

A team of scientists based out of the University of Florida has created a way of printing 3D objects suspended in a near solid structure, opening the door to the printing of complex organic structures.

There are currently methods for printing organs, which is a pretty incredible sentence to type, but these are met by the hurdle that soft materials are difficult to print in a way that they maintain their structure during the printing process. This has meant that complex organs that require space in their construction (like the heart with its many chambers) are incredibly difficult to print.

In the paper published on Science Advances, the team led by Christopher S. O’Bryan has vaulted this hurdle by printing directly into soft solid structures made of micro-organogels that can hold soft structures in place during printing.

Vigorous fluid pumping

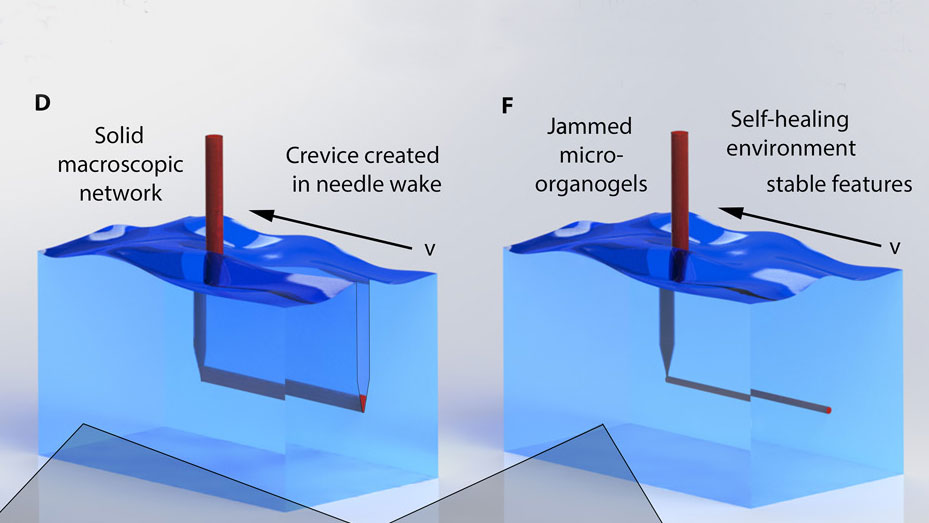

The specific viscosity of these gels are a vital part of the process, as if the printed material was suspended in a liquid, there would be no way of ensuring accurate placement as the printed matter would float away. If a solid was used, the placement would be accurate but the stabilizing structure would be damaged by the needle and it would be impossible to print above an area that had been printed into.

The microgel that is being used remains in a solid state until it comes into contact with an applied stress, in this case the needle being inserted. Once the printed material has been deposited by the needle, the microgel turns solid again meaning that the printed matter stays exactly where it was placed and the track of the needle 'heals' allowing for another layer of printing.

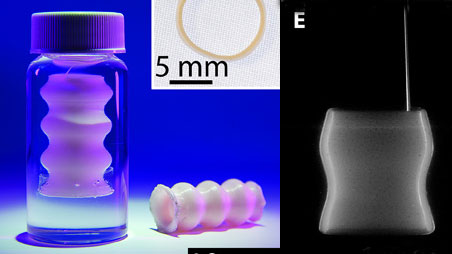

At the moment the team is only printing silicone structures using this method, so we’ll still have a while to wait to see if this method can be used to print organic matter in the same way, but medical implants are clearly an imperative; one of the trial objects was a human tracheal implant.

From the closing section of the report: “The micro-organogel system developed here allows for the fabrication of devices suitable for biomedical applications that are robust enough to be handled, tested with standard industrial mechanical methods, and used in vigorous fluid pumping applications”.

Sign up for breaking news, reviews, opinion, top tech deals, and more.

While vigorous fluid pumping actions may not sound particularly exciting, for the thousands of people a year that require organ transplants it could be genuinely life-saving.

Via Hackaday

All images courtesy of Science Advances

Andrew London is a writer at Velocity Partners. Prior to Velocity Partners, he was a staff writer at Future plc.