Meet the team who want every smartphone waterproofed in five years

P2i tells us about the future of nano-tech waterproofing

The first step in the process of making a smartphone waterproof (without changing its design) involves placing the device into a vacuum, which will suck all the air from inside and around the handset. Once finished, a special plasma process that is both difficult to explain, and highly secretive, is used to apply a proprietary coating to every part of the device.

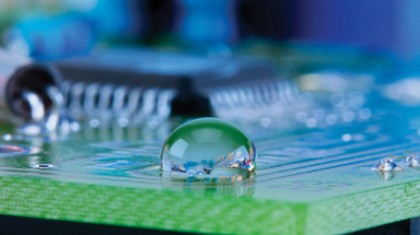

This coating is 1000 times thinner than a human hair, and works by lowering the surface energy of everything inside and outside the phone. So rather than the water sticking to the device, it forms a droplet and rolls off.

After being shown how the phones are waterproofed, P2i's engineers gave a number of demonstrations to prove just how effective the new Dunkable technology is. Thanks to the plasma process there is apparently no limit to the amount of times a smartphone can be submerged once the liquid-repellent nano-coating is applied.

The only problem is that it's unlikely current generation touchscreens will work underwater, though it's possible that developments in capacitive technology will make this a reality in the future.

P2i had lots of ways of proving the functionality of its technology, but none were simpler than showing how water interacts with a nano-coated paper tissue. Without the coating, the tissue is designed to be absorbent and will soak up water. Once treated, the tissue becomes water repellent or 'hydrophobic' and liquids will simply roll straight off.

This process is almost identical to that described by California-based HzO, but how the process is done without infringing on P2i's patents remains to be seen.

Coulson noted that P2i is "working with the top 10 manufacturers of mobile phones" to progress towards all phones having a waterproof coating as part of their specification within the next five years.

Sign up for breaking news, reviews, opinion, top tech deals, and more.

This may seem like a relatively long time in the continually progressive smartphone lifecycle, but fitting the necessary equipment into the huge production lines of global smartphone manufactures is far from an overnight process.

So far P2i has publicly shown processing chambers of up to 2000L, capable of coating 600 phones simultaneously. Though when you consider that Samsung ships approximately 75 million smartphones every quarter, you soon start to understand the necessary scale of operation required.

P2i has sold much larger machines to some of its customers, though it couldn't reveal exactly who. These larger machines are capable of processing up to 100,000 phones a day at a cost of less than £1 (around $1.50 ,$AU1.80) per unit.

At the moment, the scale of the technology used puts it outside the reach of home users or retail opportunities. However, within the next five years it's hoped that nano-coating machines will be small enough to be much more widely used.

P2i's CEO Carl D. Francis is more wary about allowing home users free-roam with this technology saying: "we could put retail kiosks in shopping centres, but we thought that it may cause problems with the manufacturers warranties.

"So we decided we didn't want to start there, and that starting with the manufacturers would mean we'd get an approval from them and we'd work with them to improve reliability."

More than waterproof

Francis doesn't see a place for water defences outside the invisible world of nano-coatings, saying "The trend is going towards thinner, lighter devices, meaning the ability to build in gaskets and membranes as some manufacturers have experimented with, is a far tougher proposition than to apply a coating at a nano level."

With earlier forms of P2i's technology having been around for a couple of years, you'd wonder why all manufacturers haven't already embraced the technology.