LG will test a next-gen OLED TV tech that's way more efficient – here's why it could be a big deal

This could be a giant eLEAP for TV tech

Sign up for breaking news, reviews, opinion, top tech deals, and more.

You are now subscribed

Your newsletter sign-up was successful

- LG will test a new OLED production method for its TV panels

- Potentially brighter, more efficient OLED TVs with less risk of burn-in

- Likely to appear in niche sectors such as in-car displays first

Some time ago we reported on a new kind of TV tech called eLEAP that could solve the long-running problems with the best OLED TVs – and three years since it was announced, it looks like LG could end up putting it into production.

It's known as eLEAP, and it's an alternative way of manufacturing OLED panels. When it was announced in 2022, its focus was on small phone screens. But LG Display is looking at the tech for significantly larger displays, and that means it could be – oh yes – one giant eLEAP for TV technology.

Why eLEAP could transform TVs

Conventional OLED panels are made with fine metal masks, which are thin metal plates with lots of tiny holes in them. Those masks ensure that organic material is deposited on the display substrate with pixel-perfect precision to ensure that each pixel lights up uniformly without overlapping or being poorly aligned.

eLEAP does things differently. Instead of fine metal masks it uses a lithography process to create the OLED pixels. And according to trade site The Elec, LG Display already has the appropriate equipment to trial eLEAP in its OLED facility in Paju, South Korea – and it's looking to test on TV-sized panels. Samsung Display is also reportedly testing the technology.

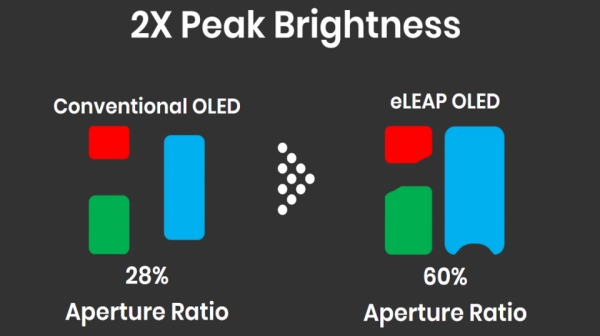

This is a trial, not the beginning of production: LG Display and Samsung Display may still decide not to go ahead with the tech. But it does have the potential to transform OLED manufacturing: the promise of eLEAP is that it'll offer far better efficiency for the OLED pixels, because the light-emitting area is more than doubled compared to a pixel of the same size made using the fine metal mask technique.

That means they're much more energy efficient, so you could have higher brightness without increasing power use – or use less power at the same brightness. That energy efficiency also means less heat generation – and heat is a key cause of OLED burn-in, so there'd be little danger of the higher brightness causing a burn-in problem.

There is also the potential for eLEAP to be more efficient to actually produce, which would mean cheaper OLED panels, which may mean cheaper TVs – or, at least, maybe mid-range OLEDs such as the LG C5 could finally get significantly brighter without becoming as expensive as the flagship LG G5.

Sign up for breaking news, reviews, opinion, top tech deals, and more.

However, even if the trials are successful it's likely to be some time before we'll see the tech in our TVs: according to The Elec the short-term use case is in "niche OLED panels, such as those 20-inch to 30-inch in size or those used in vehicles." However, the fact that LG is testing it in panels of TV size at all is great news for its potential use in the future for better home entertainment.

You might also like

Contributor

Writer, broadcaster, musician and kitchen gadget obsessive Carrie Marshall has been writing about tech since 1998, contributing sage advice and odd opinions to all kinds of magazines and websites as well as writing more than twenty books. Her latest, a love letter to music titled Small Town Joy, is on sale now. She is the singer in spectacularly obscure Glaswegian rock band Unquiet Mind.

You must confirm your public display name before commenting

Please logout and then login again, you will then be prompted to enter your display name.