The 3D 'microbatteries' that could power ultra-low energy wearables

Image a battery that can be charged in seconds

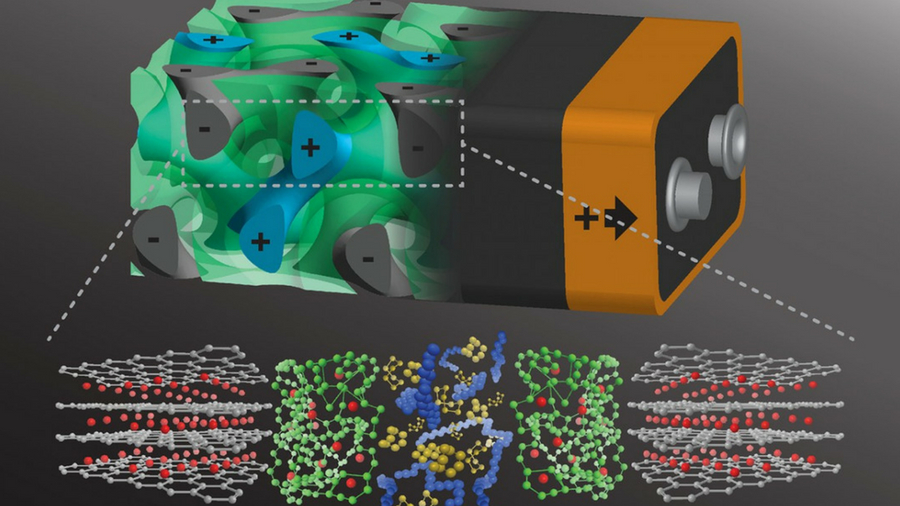

Main image: The future of wearables and IoT sensors depends on better batteries. Credit: CC0 Creative Commons

Fitness trackers, smartwatches, clever earpieces and other incredible wearables are the first wave in a new era in electronics. Most are hamstrung by limited battery power, so the next wave – an army of tiny sensors that autonomously transfer data to other devices, better known as the Internet of Things (IoT) – will rely on a revolution in battery technology. Cue 3D microbatteries.

How do batteries work?

Batteries have a negative (cathode), and a positive (anode) electrode made from metal, with a non-conducting electrolyte in between that supports electrically charged atoms, typically lithium ions, traveling between one and the other. When all those atoms are on the positive side, the battery needs recharging, after which the atoms (now with a supply of electrons) then travel the other way.

Given the size limitations of the standard lithium-ion batteries found in almost all portable electronics, from phones and cameras to Bluetooth earphones and wearables, scientists are constantly on the hunt for smaller and more efficient designs.

What is a 3D battery?

A 3D battery is a complete redesign of how existing batteries are constructed, in order to make them either more powerful, or smaller. Instead of a layer of anode, the electrolyte, then a layer of cathode, a 3D battery has 3D-shaped anode and cathode that are more like puzzle pieces. Such a design increases the surface area of the cathode and anode, and can either hold more lithium ions, and so offer more power, or be many times smaller than a traditional battery. Effectively, 3D designs increase the energy density of batteries.

What has UCLA done?

Researchers at the University of California, Los Angeles (UCLA) have created a powerful 3D lithium-ion battery no bigger than 100 grains of salt. In their paper High Areal Energy Density 3D Lithium-Ion Microbatteries published in Joule in May of this year, they outlined not only a 3D battery, but a new way of constructing it using the same techniques used to manufacture electronic circuits – that's key, because although better in theory, 3D batteries have so far proved difficult to construct.

Instead of layers, the UCLA team's ‘concentric-tube’ design uses 3D anode posts covered by a thin layer of a photo-patternable polymer electrolyte, with the region between the posts filled by the cathode material. The end result had an energy density of 5.2 milliwatt-hours per square centimeter, which is pretty good for a 3D battery. However, even more important for use in tiny devices was its small size: just 0.09 square centimeters. Wow.

Sign up for breaking news, reviews, opinion, top tech deals, and more.

How important is this?

More work is needed on components, assembly and packaging, but it could mean 3D microbatteries for IoT applications are easier to manufacture. "For small sensors, you need to re-design the battery to be like a skyscraper in New York instead of a ranch house in California," said Bruce Dunn, professor of materials science and engineering at UCLA and senior author of the report, about the team’s use of cathode posts.

"That's what a 3D battery does, and we can use semiconductor processing and a conformal electrolyte to make one that is compatible with the demands of small internet-connected devices."

The battery that recharges instantly

The amount of power a battery can store becomes less important if it can be recharged very quickly. Think about Apple AirPods and other 'true wireless' earphones; if they could be recharged in under a minute, would anyone care how long the battery actually lasted? And what if those batteries could be recharged in less than a second?

What has Cornell University done?

There are other ways of making 3D batteries that could mean wearables and IoT devices could be recharged almost instantly, as proven by a team at Cornell University, which sought to intertwine the components inside a battery. In place of the standard cathode-electrolyte-anode design, they designed a 3D gyroidal structure with thousands of nanoscale pores filled with all the battery's usual components.

"This is truly a revolutionary battery architecture,” said Ulrich Wiesner, professor of engineering in the Department of Materials Science and Engineering. “This three-dimensional architecture basically eliminates all losses from dead volume in your device.” He also pointed out that by shrinking everything to the nanoscale, you get orders of magnitude higher power density. "So you can access the energy in much shorter times than what’s usually done with conventional battery architectures."

So how fast will its 3D battery recharge? "By the time you put your cable into the socket, in seconds, perhaps even faster, the battery would be charged," said Wiesner. The team's paper Block Copolymer Derived 3-D Interpenetrating Multifunctional Gyroidal Nanohybrid for Electrical Energy Storage was published in Energy and Environmental Science in May 2018.

The flexible battery for wearables

Both of these 3D batteries are an attempt to breathe new life into the lithium-ion battery, but some think a whole new kind of battery is needed for flexible (and even stretchable) wearable devices – think smart clothes for fitness pursuits that constantly collect and send data on all kinds of body metrics.

Lithium–sulfur (Li–S) batteries are one option that's been explored by a team of researchers in Korea, in a paper published in the Journal of Materials Chemistry. The team demonstrated a new class of battery that uses an all-fibrous cathode–separator and carbon nanotubes to create a metallic foil form factor. As well as exceptional improvements in energy density, that mechanical deformability means the batteries can be crumpled without being affected.

With the IoT growing at an exponential rate, and with the wearable fitness tracker market alone reckoned to be worth $48.2 billion by 2023, there's going to be a massive and growing demand for tiny batteries that boast higher capacity, can be recharged quickly, and can even bend and flex – and more power to whoever can make them commercially viable first.

TechRadar's Next Up series is brought to you in association with Honor

Jamie is a freelance tech, travel and space journalist based in the UK. He’s been writing regularly for Techradar since it was launched in 2008 and also writes regularly for Forbes, The Telegraph, the South China Morning Post, Sky & Telescope and the Sky At Night magazine as well as other Future titles T3, Digital Camera World, All About Space and Space.com. He also edits two of his own websites, TravGear.com and WhenIsTheNextEclipse.com that reflect his obsession with travel gear and solar eclipse travel. He is the author of A Stargazing Program For Beginners (Springer, 2015),