How computers have revolutionised our cars

Meet the computer models making cars more efficient and building factories

Computer modelling is becoming an increasingly important part of car design, chopping testing times down to a fraction of what they were and enabling engineers to innovate and tinker with greater ease.

In fact, Mercedes-Benz performed computer modelling to test solutions for better aerodynamics in its new CLA, Chrysler is using state-of-the-art models to design better factories and Ford is analysing the MPG of a C-MAX Energi.

It seems computer modelling is here to stay in car manufacturing. Let's see how this all works.

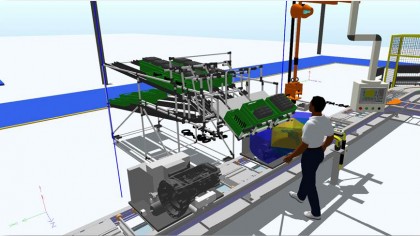

Chrysler builds a better powertrain factory

As we enter an age of connected devices and The Internet of Things, more and more data will be available to help automobile manufacturers build cars more efficiently. Computers already help track inventory, but Chrysler has developed new models that track where the specific parts are located in a factory, and even the motion a worker needs to perform to install the part.

Brian Harlow, the Chrysler vice president in charge of powertrain manufacturing, says the company now uses "world class manufacturing". 3D models simulate safety, installation and risk analysis for the powertrain and engine assembly. "We want to make sure employees are not using extra time placing a part where it needs to go," says Harlow.

One example is with a transmission sub-assembly. It might involve a cylinder that is 15 inches long and 8 inches in diameter. The company created computer models that show the exact placement in the factory and which motion will optimise the installation. Workers can see exactly how the part should be installed, where, and with which motion.

Harlow says this is just the beginning. In the future, Chrysler might create models that go much further, showing how the parts were obtained and delivered to the factory and even modelling what happens after the installation and how the part can be optimised for the longest life in the vehicle - including which materials to use for those components.

Sign up for breaking news, reviews, opinion, top tech deals, and more.

Interestingly, while this "world class manufacturing" is designed to model factory assembly, the goal is to optimise the installations for humans, not robots.

"There is an intellectual property you get with humans that you don't get with robots. Robots only do what you program them to do. A human worker can avoid damage to expensive parts and give feedback about the safety handling and ergonomics involved with the installation," says Harlow.

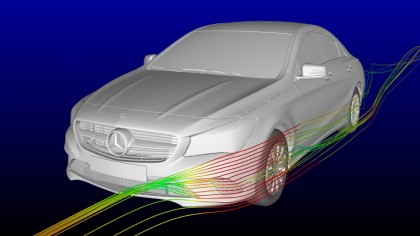

Mercedes-Benz tests aerodynamics of the CLA

This compact four-door car from Mercedes, new for 2014, was designed in a vacuum - well, in a way. Designers turned to virtual aerodynamic testing (essentially, a computerised wind tunnel) to make sure the vehicle would hit their targets for styling and energy efficiency.

"Using CFD data (computational fluid dynamics) we get a better understanding of the airflow around the vehicle and especially through the vehicle, like cooling airflow, airflow in wheel arch housing and underbody," says Patrick Höfer, who leads the Mercedes-Benz aerodynamics compact cars team that worked on the CLA.

Höfer says Mercedes generates what he calls "flow visualisation pictures", which reveal problems in the aerodynamics. The company can see every streamline on the car and the physical data it needs for efficiency, such as pressure distribution and wake structure.

One of the specific areas they analysed was the airflow around the front wheels. "The results are noticeable in the shape of the front wheel spoiler and in the serrated wheel arch liner," he says. "Due to the optimisation, the airflow goes under the whole front wheelhouse cavity, which helps to have a better working diffusor downstream. The front wheel spoiler works like a deflector of a sun roof, where the teeth create longitudinal vortices to help stabilise the shear flow [the force caused by a gradient] over and under the cavity."

John Brandon has covered gadgets and cars for the past 12 years having published over 12,000 articles and tested nearly 8,000 products. He's nothing if not prolific. Before starting his writing career, he led an Information Design practice at a large consumer electronics retailer in the US. His hobbies include deep sea exploration, complaining about the weather, and engineering a vast multiverse conspiracy.