Burning up - new materials could lead to safe hypersonic flight

Faster, faaaaaaster

While sending a message around the globe is getting easier and faster, transporting our actual human bodies still takes an intolerably long time. Part of the problem is that in order to move us from one part of the planet to another requires a mode of transport that unfortunately has to obey the laws of physics.

While Hyperloop seems to be making progress in the field of tunnel travel, we’re probably a long way away from seeing a tunnel that runs under the sea between countries. And teleportation sadly isn’t a thing on anything more than the quantum level. So our best hope is taking a mode of transport that already exists and making it better.

Thankfully, there has recently been a breakthrough that could mean we are one step closer to hypersonic flight, both for commercial flight, and space travel.

Hypersonic transport is the practice of moving at Mach five. That’s five times the speed of sound. Once you you start getting up to those sorts of speeds, the air around your vehicle heats up to between 2,000 and 3,000°C, and the hot air literally starts stripping away the surface of the vessel in a process known as ablation.

Sonic boom!!!

Just to put hypersonic flight into context, it would be over a thousand miles per hour faster than the Concorde. Flying at hypersonic speed means travelling at speeds close to 4,000 miles per hour. With takeoff and landing, that means a two hour flight from London to New York, with longer journeys like New York to Sydney possibly seeing even greater benefits.

The problem is, even in pre-existing modes of transport like the Concorde plane, the hull would heat up over the course of a flight, and the windows and walls would be too hot to touch by the time you land. And that’s not even hypersonic.

In order to counter the massive overheating associated with travelling at hypersonic speed (which we’re still not bored of saying), materials called ultra-high temperature ceramics (UHTCs) are needed to coat the surface of the vehicle. According to Phys.org, conventional UHTCs can’t currently satisfy ablation requirements.

Sign up for breaking news, reviews, opinion, top tech deals, and more.

Now, a team of researchers at The University of Manchester in collaboration with Central South University of China has designed and manufactured a new carbide coating that is much better at resisting the 3,000°C temperatures associated with hypersonic flight.

Apparently the new material is proving to be twelve times better than standard UHTCs, thanks to its structural make-up. It is made using a process called reactive melt infiltration, which as well as sounding like something straight out of Star Trek, also makes the material much stronger than usual UHTC’s, and much faster to produce too.

There is no news about how long it will be before we start seeing this new technology in actual planes but as always, as soon as we know, you’ll know.

- Want some more news about the future of travel? Check out: Hyperloop One plans to get you from London to Edinburgh in 50 minutes

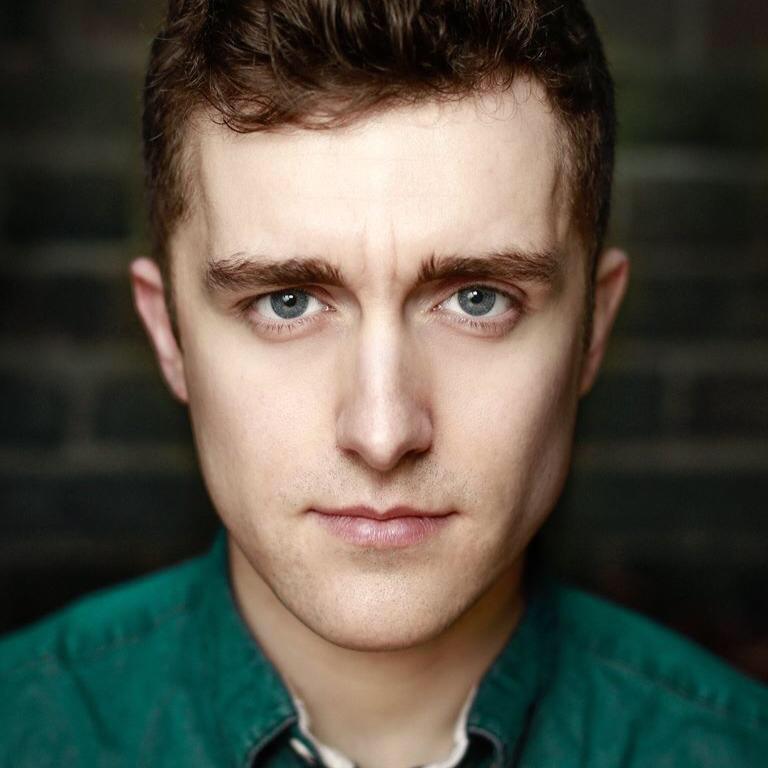

Andrew London is a writer at Velocity Partners. Prior to Velocity Partners, he was a staff writer at Future plc.