That's the position the music industry found itself in, and therefore had to adapt and now we have Spotify. That seems to be the way things go: the established industries find that their market is being undermined by some new technology, so it tries to regulate.

TR: Talking of legislation, there were the guys that printed their own gun…

AB: There's a law that says you can't export designs for weapons in the United States and I suspect there is probably something similar in the UK too. I don't know. Distributing a file in that case becomes illegal.

The printed gun was frightfully, frightfully depressing from my point of view. Not because of the gun - the gun is useless and it represents no real danger. The thing that was terribly depressing was the horrible exposure it gave to the complete ignorance among journalists and politicians about how things are made.

If you want to make a proper gun - a real gun that works - get a lathe. People have owned lathes for 200 years, ever since the industrial revolution. You can go on Ebay and buy one for about the same cost as a 3D printer. My recommendation to anyone buying a 3D printer to make a gun is not to bother.

TR: Do you have any numbers on the uptake of 3D printers?

AB: We certainly don't know how many RepRaps are out there. Our company sells thousands per year, and we are just one of a score of such companies. We don't know what the ratio is between private builders and commercial companies selling kits. There must be tens of thousands out there, possibly even hundreds of thousands - we simply don't know.

Sign up for breaking news, reviews, opinion, top tech deals, and more.

There was an attempt a few years ago to do a statistical survey to estimate the population of RepRaps. Rather cleverly, using some of techniques that biologists use for assessing populations - such as evaluating how many foxes there are per square mile - you can carry out statistical estimates of numbers. You obviously can't go and count them all!

So three or four years ago, they came up with the answer of several thousand. The number has increased exponentially since then.

TR: They've been busy replicating themselves!

AB: Well, quite. An awful lot of people print machines for their friends. One of the things I can tell you is that the ratio of uptake between private individuals and commercial organisations is about 80:20. About 80% of machines go into private hands, while 20% go to schools, companies and the rest, which I find quite encouraging.

TR: We presume these are tech-savvy folk?

AB: Yes. Occasionally people get a little out of their depth when they're building a machine. But of course, because the instructions are online, people can read them all. Before even getting a machine, they've got a pretty clear idea of what's involved and can either be put off or can say, "Yeah - I can do that!"

TR: Where do you see 3D printers going?

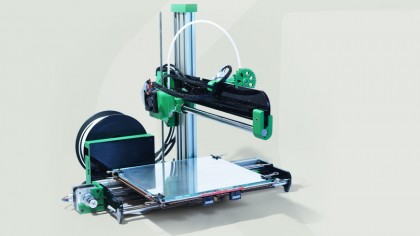

AB: They're becoming easier to use and put together. We've got a new RepRap coming out that's deliberately designed to be far easier to assemble. The previous machine would take about 20 hours, when being assembled by someone who knew what they were doing. In contrast, this one will take two hours and we want to progress in that direction.

If you've got a machine that is genuinely self-replicating, then any time required for human intervention is a significant impediment to its reproductive success in biological terms. If you can put one together in five minutes, then that's much better. So all RepRap companies are working towards improving the self-assembling machine.

There's another thing that you can do with the machines. We have a bendy plastic and a rigid plastic, and you can vary proportions so you have an object that's rigid at one end and bendy at the other.

There is virtually no other conventional technology that lets you do that as a single item. But it's a trick biology uses all the time - this bit's bendy [pushes nose] and this bit is rigid [points to arm].

TR: So do you see this opening up new manufacturing techniques?

AB: And new types of products that are simpler but with more complex functionality. If you can change the material properties of an object in a controlled way, then you can achieve an awful lot more.

Virtually everything that has been manufactured is made of different materials, but there is a sharp transition and they're made in different processes.

If you can make them all in one process and have graduation between them and mixtures between them, then you can do an awful lot more. It liberates you in terms of how you design things and how machines work.