The muscles of our robot overlords will be made of nylon

Simple, inexpensive and effective

Artificial muscles are used in a bunch of industries - from robotics to aviation. But the exotic materials used in their construction are both expensive and difficult to source.

Now, engineers at MIT have come up with an alternative that's cheap, ubiquitous and effective - nylon fibre. And with it, they've designed one of the simplest and low-cost artificial muscle systems yet.

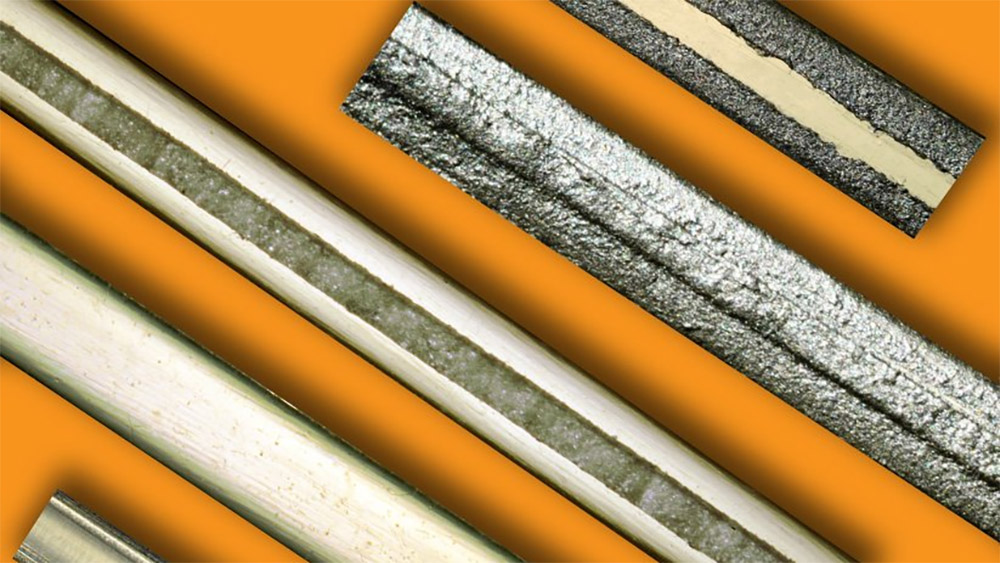

The work was underpinned by a peculiar property that nylon exhibits - that when the fibre is heated, it shrinks in length but expands in diameter. As a result, if you just heat one side then it'll bend. Using this knowledge, the team carefully compressed fibres so that their cross section was square rather than circular, to accentuate the bending effect.

They were then able to generate complex motions by changing the direction of the heating - getting the fibres to move in circles and figure-eight patterns. Much more complex movement patterns could also be generated, the team said.

Game-Changing

It lasts, too. Existing systems made of shape-memory alloys only manage about 1,000 cycles before losing their ability to contract, but a nylon system can maintain its performance up to at least 100,000 cycles. It can also bend and retract up to 17 times per second.

Beyond powering robot muscles, the system could be used to make clothes that adjust to your body, make self-lacing shoes, or biomedical devices. Down the line, it could even lead to vehicles that change shape to adjust to changes in wind speed or solar panels that automatically keep themselves aimed at the sun.

Andrew Taberner, a bioengineer at the University of Auckland who was not involved in the research, said that the findings were "exciting and game-changing". “One can imagine many applications for this type of actuator in the medical and instrumentation fields," he added. "I expect that this work will become highly cited."

Sign up for breaking news, reviews, opinion, top tech deals, and more.

The full details of the research were published in the journal Advanced Materials.