MacBook Air M3 teardown proves Apple’s laptop remains much the same inside – except for one important upgrade

Vital change to storage confirmed by teardown for both 13-inch and 15-inch laptops

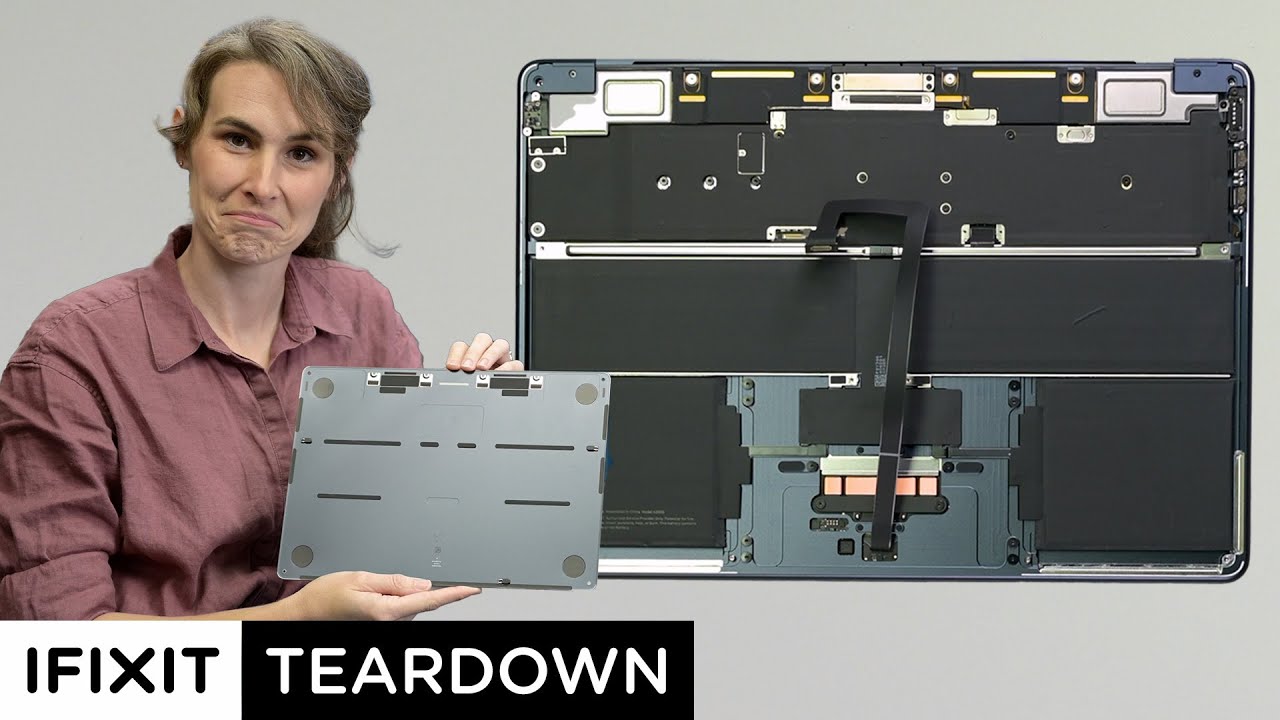

Apple’s MacBook Air M3 has just been released in 13-inch and 15-inch flavors, and that means the inevitable teardown has just arrived, with iFixit taking the laptop apart to confirm one major improvement over the M2 models.

Namely that Apple has indeed used two 128GB modules for the SSD, rather than a single 256GB chip, in the base MacBook Air 13-inch with M3 – plus iFixit confirmed the entry-level MacBook Air 15-inch also has this dual module configuration for its storage, as MacRumors reports.

Why is this so crucial? Using two modules allows for running tasks in parallel for considerable performance benefits, as underlined by Max Tech on YouTube (as we reported previously).

In fact, the MacBook Air M3 has up to 80% faster read speeds and up to 33% faster writes than the base model of the M2, so it’s quite the difference.

With iFixit’s teardown, it’s good to have it confirmed that the MacBook Air M3 uses this 2 x 128GB configuration for both the entry-level models of the 15-inch and 13-inch versions (incidentally, the latter now tops our ranking of the best laptops).

The major finding here is that SSD change, but otherwise, this new take on Apple’s svelte laptop carries pretty much the same design as the M2 version.

Analysis: Getting it right for repairs

The new M3 models using the same design as their predecessor is no bad thing in some ways, as the M2 variant witnessed some important improvements for the repairability of the MacBook Air. Most notably a change in terms of the battery being glued in.

Sign up for breaking news, reviews, opinion, top tech deals, and more.

Apple made a move with the M2 to use a stretch-release adhesive (that can be relatively easily extracted – at least when the laptop is new) for the battery, rather than slathering glue around. And that’s again the method used for the M3 notebooks, so it’s good to have that confirmed, as well – it means replacing a duff battery is a much easier task.

There’s still work to be done for Apple, though, as iFixit observes. Another obvious improvement that could be implemented is changing the pentalobe screws on the chassis, and making the case easier to open (it’s not just about those non-standard screws, but also some strong clips that make it difficult to pry open the case).

These are easy changes to facilitate in theory, and iFixit raises the hope that ‘right to repair’ legislation in the US might make Apple mend its ways in terms of these kind of measures.

Meanwhile, work has already begun on a MacBook with the M4 chip, or so we are told.

You might also like

Darren is a freelancer writing news and features for TechRadar (and occasionally T3) across a broad range of computing topics including CPUs, GPUs, various other hardware, VPNs, antivirus and more. He has written about tech for the best part of three decades, and writes books in his spare time (his debut novel - 'I Know What You Did Last Supper' - was published by Hachette UK in 2013).