UP Mini 3D printer

Even a mini 3D printer is fun to have

Price: AUD $1,095 | From: 3D Printing Systems

From the outside, the UP Mini looks like an overgrown bread maker, but when you take a look at the box of extras, you realise this is a little more serious.

While putting it together (which was really easy), it was obvious it wasn't that different to an inkjet printer, except that it prints in three dimensions instead of two and with molten plastic, not ink.

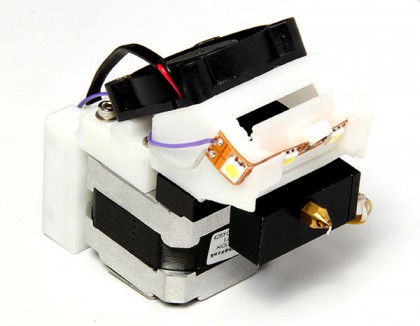

Instead of an ink cartridge, it has a reel of ABS plastic on of the unit — a single continuous filament of plastic tubing around 2mm thick that feeds into the print head, which itself is just a brilliant piece of engineering.

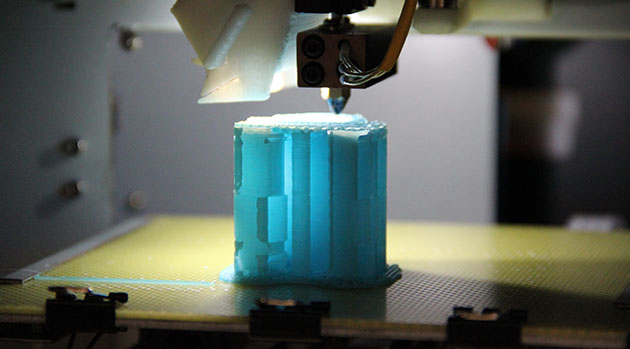

The print head not only heats the plastic up to a toasty 260°C, it contains the extruder, which squirts out a thin 0.2mm strand of molten plastic, forming the basis of your object.

But not only that, it also has a motorised feed system that continually pulls in fresh ABS plastic from the spool, which slowly spins around on the back like an old reel-to-reel tape recorder.

Let's start printing!

The temptation really is to rip through the setup as quickly as possible so you can start printing something, but time spent here is saved at the other end when you're holding your perfectly-shaped printed object in your hand.

Sign up for breaking news, reviews, opinion, top tech deals, and more.

The UP Mini can handle a maximum object size of 120mm high, wide and deep. That doesn't seem all that big, although the great thing about 3D printers is you can break down your designs into parts that you can put together later. So in a way, a 3D printer is really your own do-it-yourself LEGO machine.

You can design your own objects using 3D modelling software (we show you how this works in our May 2013 issue of TechLife Magazine from the App Store) or you can cheat and download models from Thingiverse.

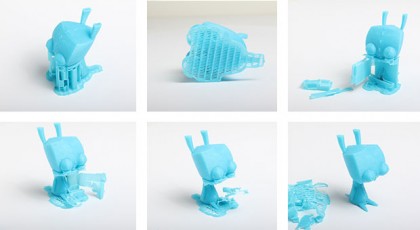

The UP Mini requires objects in the .STL file format, which is the standard modelling format, and Thingiverse has thousands of objects you can download for free and print. We downloaded a range of models from a Companion Cube and cute cartoon characters to a Raspberry Pi computer case.

Since objects are broken down into a series of horizontal layers, the printer has to be careful, particularly in designs where there are narrow sections followed by larger, wider parts; for example, a cartoon character's neck and head.

It's here where I thought this thing moved from clever to totally brilliant. Without information in the .STL file or me having to program it, the printer automatically knew where it needed to create its own support structures — like little plastic scaffolding — to support the object as it was being built and it automatically builds these structures as it goes. That is bloody clever stuff!

The results

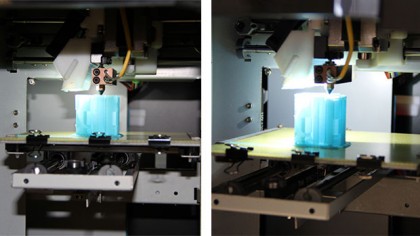

Our first print took around half an hour, with the entire editorial team wandering around like expectant aunts and uncles.

Finally, the UP Mini beeped its success and we pulled out our new baby octopus.

Getting it off the perfboard base took some careful work with the supplied spatula, but the amazing thing was that we could carefully pull off the scaffolding, trim each object with the supplied artwork knives and it was done.

The printer comes with protective glasses to protect your eyes from stray bits of flying plastic as you clip, cut and scrape away the scaffolding.

The build table has built-in heating and this keeps wider, flatter objects from curling, although it's best to preheat the table before printing.

Our arctic air-conditioned Labs were a bit too much for the preheating, but our editorial area provided the perfect location.

At $60 for a 700g roll of plastic, our Companion Cube and octopus cost around $1 each to make.

What we think

I'm rarely gobsmacked by new technology these days, but 3D printing has such a potential to change the way we live, it's hard to get your head around it.

If there's an industrial design student in Australia who isn't begging their school to get one of these, I'll eat my hat.

I can't think of a simpler, more practical way to get students thinking about real-world design than being able to design, make, break and make better their own 3D objects.

For the rest of us, there are so many applications, from home repairs to micro-manufacturing and kitchenware. The list is truly endless.

Find out more about 3D printing in our May 2013 issue of TechLife magazine from the App Store which includes a 3D Printer buyer's guide, a step-by-step guide on how to get started on 3D printing, and more.