Samsung reveals how it learned from its past foldable phone mistakes to make the Galaxy Z Fold 3 and Z Flip 3

How to make durable foldables

Sign up for breaking news, reviews, opinion, top tech deals, and more.

You are now subscribed

Your newsletter sign-up was successful

Samsung's first-ever foldable phone was the original Galaxy Fold, launched to fever-pitch excitement in early 2019 - but just a few months later, when the device was nearing release, a sea change almost scuppered Samsung's fledgling entry into the foldable space.

When test units were sent out, journalists quickly found that the Galaxy Fold had durability issues, with the hinge and screen breaking after just a few days of use on many reviewers' test models. Confidence in the Fold was shaken, and although Samsung did postpone the phone's launch by a few months, and eventually managed to launch a phone that was impressive and futuristic, durability quickly became the most important factor for future foldable.

Years have passed, and folding phones are in a different place: lots of competitors have hit the market, with one-offs like Oppo's Find N, Xiaomi's Mi Mix Fold and Honor's Magic V joining the multitude of handsets that Huawei and Motorola have put out. And since 2019, perhaps because of or despite this competition, Samsung's newer devices, like the Galaxy Z Fold 3 and Z Flip 3 haven't seen the widespread durability concerns that plagued their ancestor.

That's not a coincidence though, and is due to a few key design features and tweaks made by Samsung to protect the phone. The newer handsets can be relied on to last without snapping, having their screens peel off or letting water into every nook and cranny.

To explore the key design elements of these newer foldable phones two engineers for the company, Jinhwan Jeong of the Advanced Lab and Minsu Jung of the Advanced Mechanical R&D Group, spoke to TechRadar about the devices.

Strong frameworks

A spokesperson for Samsung explained to us that when the company was designing the third-gen Fold, as well as its Flip sibling, durability was the focus: "we decided that we should focus on the frame, which is basically the fundamental skeleton of the device".

All smartphones have a frame - it's the strip of metal that sits between the handset's screen and its rear panel, and it keeps all the components protected and safe. But for a folding phone, it has an extra function: it makes sure the moving mechanisms are all pristine and unharmed if the device takes a bump. After all, one ill-fated drop could ruin the hinge and stop the phone folding and unfolding.

Sign up for breaking news, reviews, opinion, top tech deals, and more.

Samsung's solution to protect its phones is Armor Aluminum, introduced on the Galaxy Z handsets in 2021. This is an aluminum alloy that the company calls "the strongest material used in the mobile industry", and the company used it not just for the Flip and Fold frames, but for their hinge houses too.

Samsung explained that the benefits of its aluminum alloy over stainless steel, which some other phone brands use, is that it's "lighter and stronger" - and by using a strong material for its phone frames, Samsung could use less of the substance, thereby ensuring that the Z phones could be as thin and light as possible.

"This is the strongest material used in the mobile industry"

According to the company, the new Fold is 10% more durable than the Samsung Galaxy Z Fold 2, and TechRadar was shown some imagery of a bump test against the substance. Armor Aluminum had much less of a dent from an equal force than the certain other phone metals.

Aluminum may be strong and resistant to pressure, but Samsung's engineers found a catch: when adding additional elements to the alloy to make it stronger, it "undermined the quality of the exterior that we wanted to create" - the metaphor of cooking a soup was used to explain that, when you add extra ingredients and spaces, you stop the brew being clear. In short, the phone could be strong or good-looking, but not both.

So Samsung's teams had to work on the alloy further, and add even more components, to ensure that the phone could be both strong and attractive at the same time. That's why we get things like the Bespoke Edition phones, where you can choose from a range of colors for the devices.

The two types of drop

Engineers needed to make sure the Galaxy Z Fold 3 and Z Flip 3 weren't just safe from physical drops onto the floor or hard surfaces, but the other, more insiduous kind of drop: water droplets.

Anyone who's ever frantically searched for a bag of rice to cover a wet phone, or has found that just a light splash has taken their mobile out of action, knows the damage that moisture can do to a mobile. Samsung's experts, as you'd hope, know this too.

Keeping a smartphone waterproof sounds nightmarish as it is - you've got to make sure that drops can't get in from any of the ports, jacks, speaker grilles or gaps around the frame. But that's doubly the case when you've got a folding phone like the Flip 3 or Fold 3 - the nature of the flexing display means that, when it's folded, different parts of the device are exposed at different times.

As Jung says, "the major characteristic about both foldable devices is that it opens and closes from zero to 180 degrees. And to make the folding action possible, we need to create multiple parts, and there has to be a gap between those parts to make the action smooth.

"When we were first tasked with the challenge of making the device water-resistant, I could just see that it was almost an impossible task"

"If there's a small gap or hole, it's inevitable that water might go through it. So when we were first tasked with the challenge of making the device water-resistant, I could just see that it was almost an impossible task".

At first, the attitude that was taken seemed defeatist - we were told "no matter how small the hole on the device is, water is bound to get in." So the company had to focus on how to minimize the damage that this moisture could do.

Samsung's engineers pointed out three key aspects that needed to be protected from water as much as possible: the screen, the hinge, and the Flexible Printed Circuit Board (FPCB). The latter two components bridged the gap between the two halves of the foldable phones, making them critical for waterproofing.

To ensure the display components were waterproof, a form of waterproof tape was designed - this needed to be strong and sticky to increase water resistance, but not so rigid that it'd be frail in itself. So the company had to balance these two traits to create the perfect tape.

Next up was the hinge, and the issue here was that, as an important metal component, water could cause rusting which would lead to the device not opening and closing properly.

The solution? Samsung used the same lubricants that are used to keep the parts moving, to coat the hinge parts in. This wasn't as easy as splashing some liquid about: "the existing available lubricants were water-soluble - it couldn't play its function for a long time".

So Samsung created a new form of lubricant, which was more adhesive than previous ones, to protect the parts from corrosion.

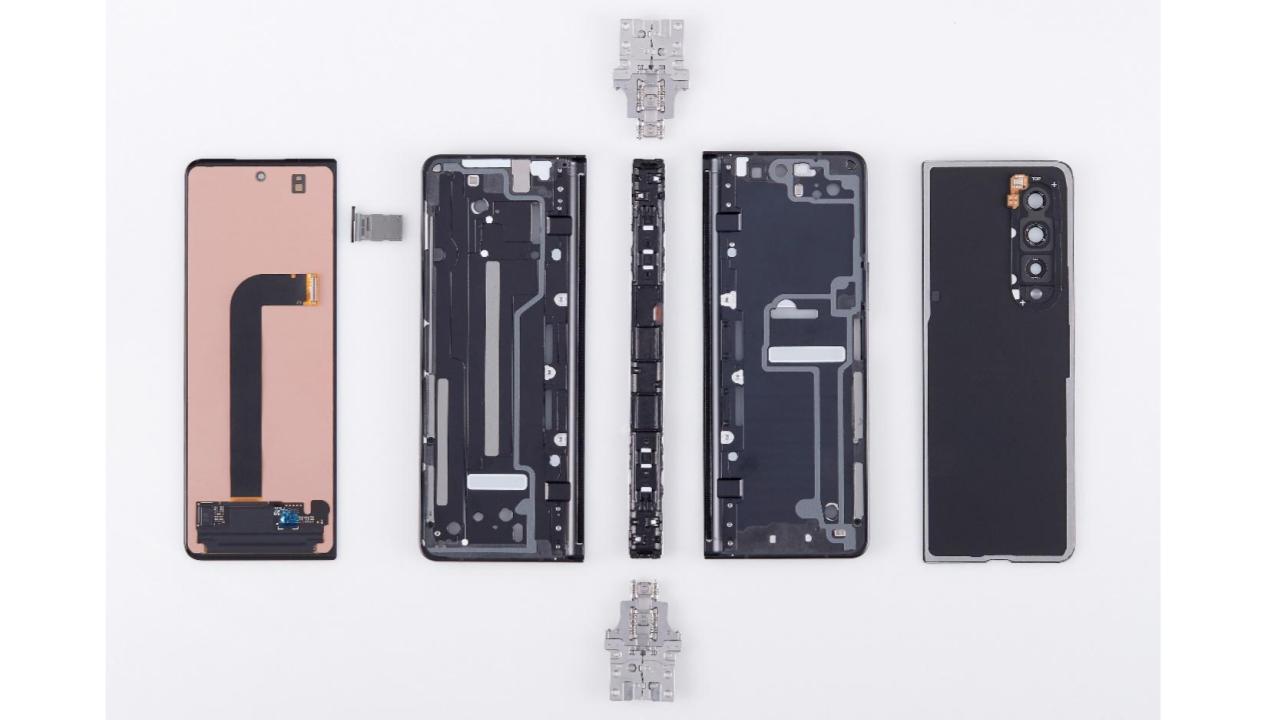

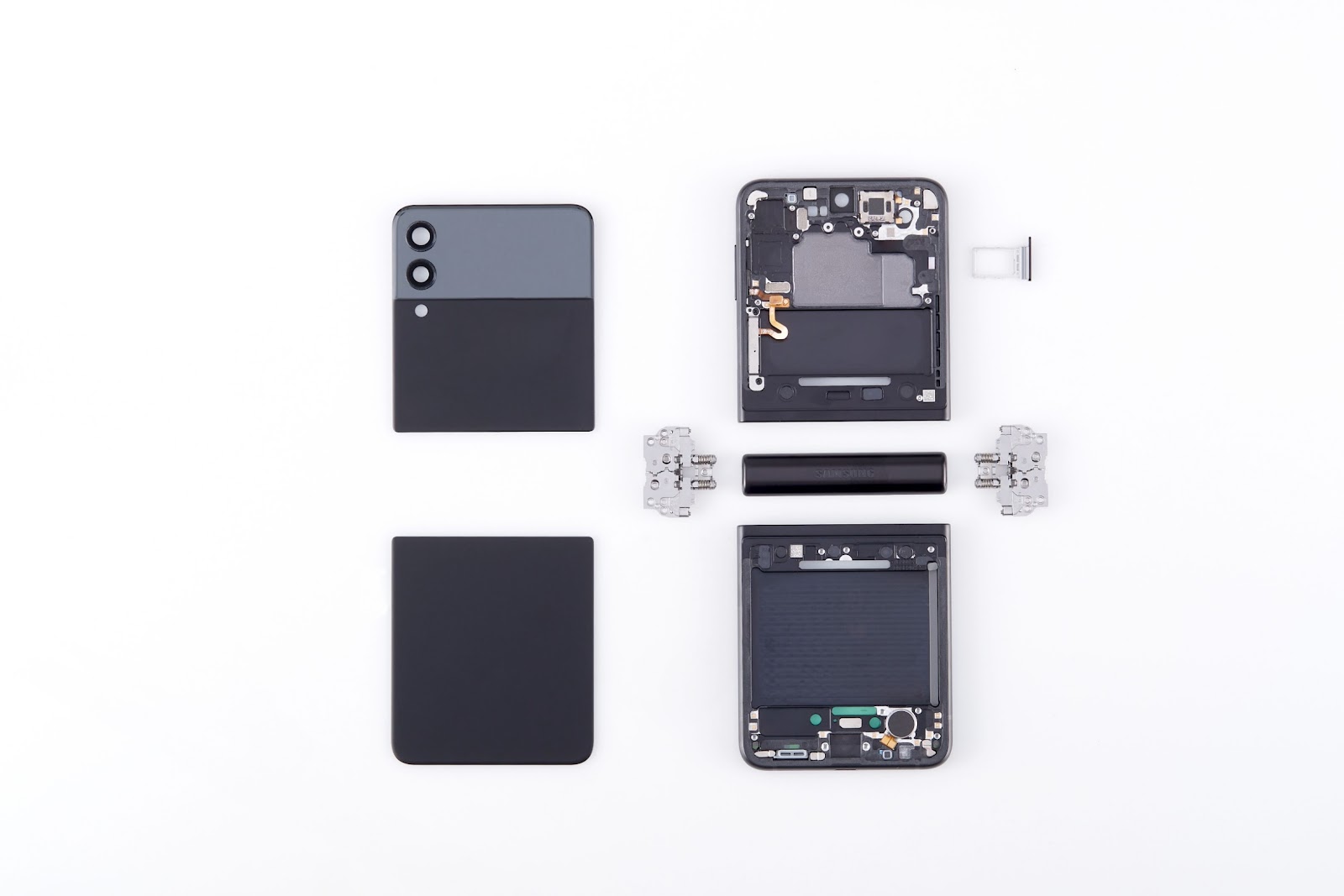

The problem with the FPCB was that it required a hole to bridge the sections - you can see this on the imagery below - which of course means any water in the body of the device could run rampant.

Samsung's engineers solved this by using a rubber bracket combined with parts called Cured In Place Gaskets (CIPG) - basically this acted like a plug to cover the gap and ensure water didn't spill through to the vunerable components.

A close brush with danger

There was one element of Samsung's durability briefing that we found particularly fascinating: just as how the company found some roundabout methods for ensuring water resistance, so too did it figure out an ingenious way of dustproofing both the Fold and Flip.

"As we said, with a foldable device, we are bound to have holes on the device that are prone to infiltration from foreign materials - dust. So the contradiction here is that if we make a gap smaller, it could inhibit the folding action of the device" Jeong told us.

So a solution was drawn up: "This is what we'd refer to as sweeper technology".

"We went through hundreds of tests just to find the right material"

A sweeper system is comparable to a cat flap on your door - lots of fibers line the edge of parts of the phone, which protrude and line gaps - but when parts move past them, these fibers can easily flex and fold to get out of the way.

Samsung's engineer described how multiple different materials were tested for these hinge bristles, including carbon fiber and Polyethylene terephthalate (PET), but nylon was the one that won out since it didn't wear out or rip as easily as the alternatives.

"We went through hundreds of tests just to find the right material," Jeong told us, "with the nylon fiber we could find the right level of resilience and rigidity, and that's what we used to perfect our sweeper technology."

Tiny brushes protecting your foldable phone's hinge - it seems like a curious image, but apparently that was the best way of protecting the phone from dust.

How long does it really last?

So, with all of those durability fixes in mind, how resilient really are the Samsung Galaxy Z Fold 3 and Z Flip 3?

Due to the fact that the phones aren't even a year old, it's hard to make any claims regarding their longevity, but the fact that the launch wasn't mired by complaints from buyers, suggests that these handsets are hardier than their ancestors.

In fact, Samsung told us that both the Fold and Flip have been designed to ensure that they reach at least 200,000 folds - for context, that's 100 folds per day for five and a half years. That's well over the life span of most phones, and 100 folds is likely more than most people make per day anyway (especially given the useful outer screen in the Fold's case).

Samsung's engineers also noted in our interview that the phones were tested both for folds done by right-handed people and left-handed ones too - your depending on your preferred side, it's possible to close folding devices in very different ways.

We don't know what Samsung worked on to make the Galaxy Z Fold 4 and Z Flip 4 even better - after all, if the company detailed its future plans, that'd likely undermine its claims of the strength of Aluminum Armor and the waterproofing and dust proofing efforts.

But when we tested the third-generation Z phones, we didn't worry about their durability or reliability, and after speaking with Samsung's engineers, we now know why we had that impression.

Tom Bedford is a freelance contributor covering tech, entertainment and gaming. Beyond TechRadar, he has bylines on sites including GamesRadar, Digital Trends, WhattoWatch and BGR. From 2019 to 2022 he was on the TechRadar team as the staff writer and then deputy editor for the mobile team.