That's why OLED displays appear so vibrant, with such deep blacks. Black OLED pixels are essentially pixels that haven't been turned on.

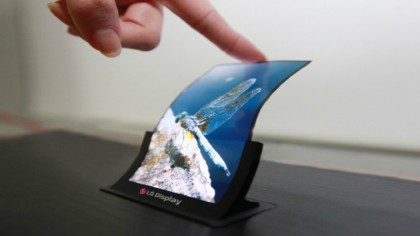

That lack of a backlight also relates to why OLED is so suited to being made flexible - and why LCD is not. OLED panels are far simpler, slimmer, and more self-contained than LCD solutions, and they can be laid on a plastic substrate rather than glass. In order words, they can stand up to being bent.

Of course, there are practical considerations when it comes to replicating this process on an industrial scale. Canatu Oy told us that "flexible backplane technology has been expensive and low yield" up to now.

We've actually had the screen technology to make flexible displays possible for some time. While there have been a number of false starts over the past 40 years relating to limited e-ink solutions, the likes of Sony have been demonstrating working flexible OLED displays since 2007.

However, those aforementioned manufacturing impracticalities have ensured that such designs never got beyond this experimental prototype stage and into a final product.

Samsung appears to have picked up the baton in recent years, and the company showed off a working flexible OLED display that it called Youm at CES 2013 (an earlier Samsung Galaxy Skin concept revealed in 2011 turned out to be the word of speculating students). This display could be worked into 'S' shapes, and formed into wrap-around display - one that goes off the edge and around the corner of a smart device.

But the key thing holding back the launch of fully flexible or foldable smartphones has nothing to do with the displays. It's everything else that makes up a smartphone that's the problem.

Sign up for breaking news, reviews, opinion, top tech deals, and more.

Power struggle

Put simply, while OLED screens can be made to bend, batteries, processors, and other vital internal components cannot. Or at least, they couldn't until relatively recently.

Back in 2011, the Korea Advanced Institute of Science and Technology announced that it had developed a fully flexible RAM chip. Enabling the reading, writing, and retention of data on a flexibly chip is essential to a fully flexible phone. Of course, refining such a concept to a practical, manufacturable level takes time, but the knowledge has been there for a while.

An even bigger obstacle in creating completely flexible phones has been creating a battery that can withstand similar manipulation. Batteries tend to take up a large part of a smartphone's mass. More problematically, they tend to be filled with liquid or gel-like substances, which don't lend themselves well to heavy flexing. In fact, doing so can be downright dangerous.

The solution has been to create a solid (or semi-solid) state battery. These will be much safer under load, and it's now just a question of ensuring that this new safe battery technology is up to the task of powering a multi-core smart device for an entire 16 hour day - something that even existing rigid battery designs can struggle with.

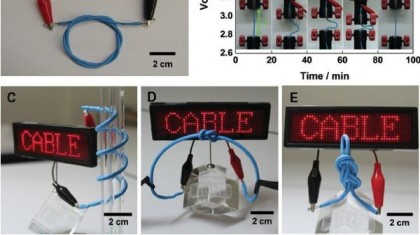

Early electronic printing techniques have proved expensive and impractical, but promising solutions to this key issue are starting to be found. Professors at New Jersey Institute of Technology (NJIT), for example, have come up with a flexible battery that utilises carbon nanotubes.

As well as being flexible, this battery technology is fully scalable. "This battery can be made as small as a pinhead or as large as a carpet in your living room," said NJIT professor Somenath Mitra.

Meanwhile LG Chem recently announced that it had produced a kind of cable battery that could be bent and even tied into a knot without heating up during use. It probably won't be ready for mass production for another few years, though.

Jon is a freelance journalist who has been covering tech since the dawn of the smartphone era. Besides TechRadar, his words and pictures have appeared in The Telegraph, ShortList, Tech Advisor, Trusted Reviews, Expert Reviews, and more. He largely covers consumer technology, with a particular focus on smartphones and tablets. However, he's also been known to dabble in the worlds of entertainment and video games.