Researchers discover how to 3D print ear, nose and knee cartilage

3D printers could one day lend you an ear

Got arthritis or a sports injury causing joint issues? Doctors may one day be able to 3D-print your problems away.

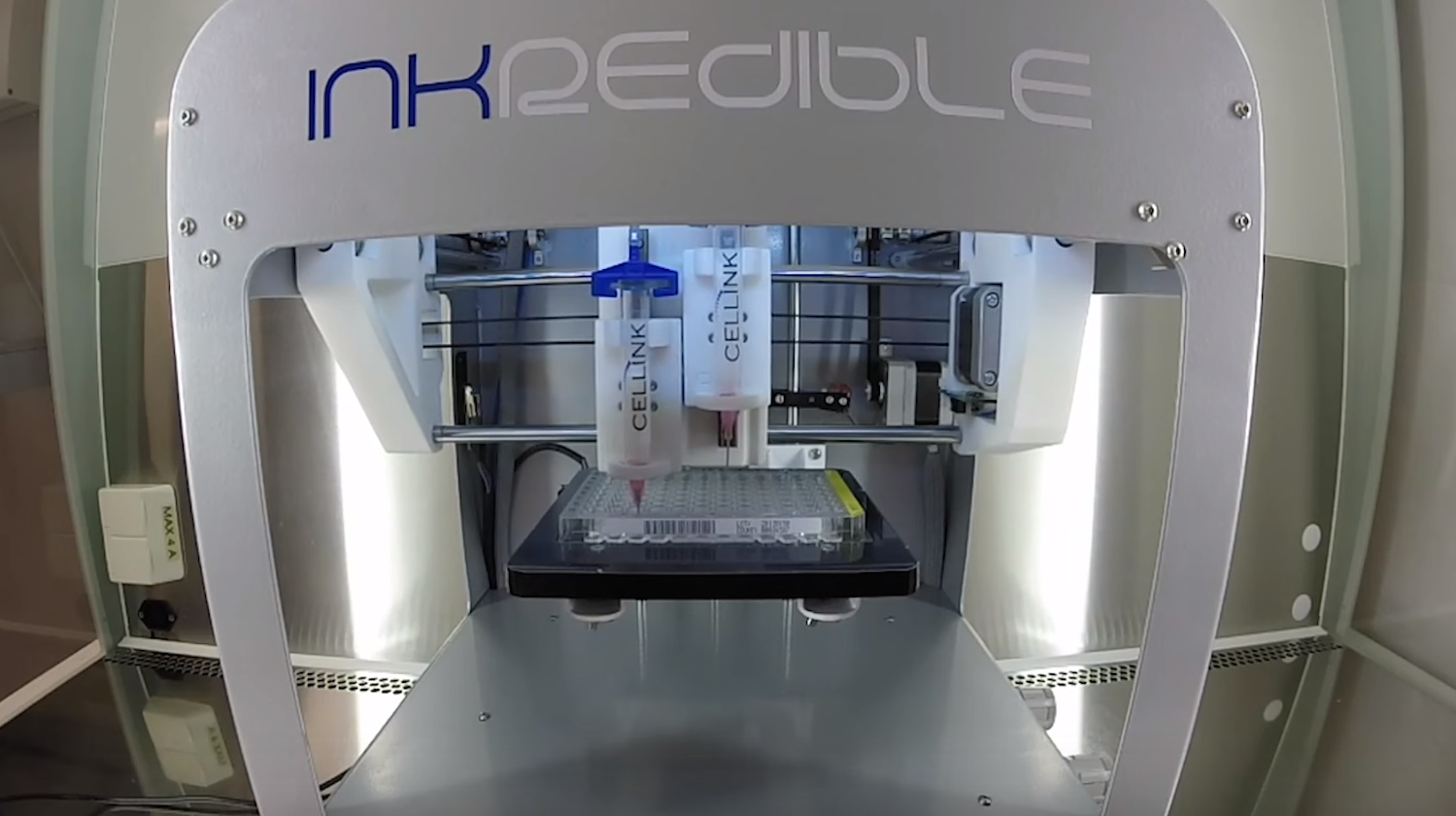

A team of researchers from Wallenberg Wood Science Center in Sweden have successfully 3D-printed cartilage tissue by developing an ink containing human cells.

"Three-dimensional bio-printing is a disruptive technology and is expected to revolutionize tissue engineering and regenerative medicine," says Paul Gatenholm, who led the research.

It could be used to one day produce 3D-printed implants to help repair injured cartilage, which can be found in the ears, nose, knees and other joints – and it doesn't grow back once damaged.

"We work with the ear and the nose, which are parts of the body that surgeons today have a hard time repairing," Gatenholm explains.

"But hopefully, they'll one day be able to fix them with a 3D printer and a bio-ink made out of a patient's own cells."

It comes down to the ink

The team explains that, previously, printed materials with human cells would collapse, and to they first had to develop an ink containing living human cells that would be able to keep its shape after printing.

Sign up for breaking news, reviews, opinion, top tech deals, and more.

In order to create an ink that could hold its shape after bring printed, the researchers mixed used human chondrocytes in, which are cells that build up cartilage.

Once 3D printed, the ink was not only able to hold its shape, but the printed cells were also able to produce cartilage in a laboratory dish.

However, while the team has successfully 3D-printed tissue samples and implanted them into mice, where it has survived and produced cartilage, Gatenholm says further pre-clinical work will need to be done before moving on to human trials.

The research is being presented to the American Chemical Society in San Diego this week.