OLED lighting on the market in 2010

GE thinks the future is flat and bendy

Sign up for breaking news, reviews, opinion, top tech deals, and more.

You are now subscribed

Your newsletter sign-up was successful

OLED lighting could be available on a commercial scale within two years if General Electric's recent manufacturing ideas go to plan.

Anil Duggan, head of GE's OLED research team, says the panels the company is creating using a printer could be ready for the market by 2010, though he agrees this is "very aggressive".

"We're trying to be as low-tech as possible," he added, highlighting one of the major problems of OLED manufacture.

Roll to roll

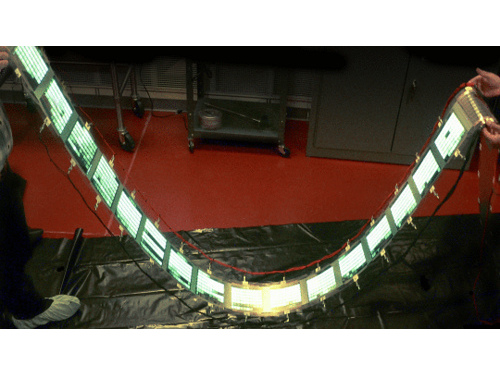

GE is currently working with roll-to-roll OLED printing, literally running the organic lighting material through a printing press in the same manner as a newspaper, a process which could lead to OLED lighting at around 60p per square foot.

However, sizes are currently limited to 8in panels, but GE will be building a machine over the next year that can run to much larger sizes.

"It's not going to be competitive with fluorescents in 2010," Duggal said, which added to the initial high cost of manufacture means the technology will be limited to high-end architectural areas.

Sign up for breaking news, reviews, opinion, top tech deals, and more.

But economies of scale will drive that down, as will improved techniques learned from display manufacture, where OLED is set to compete with LCD and plasma in the TV and monitor stakes.

"In the 1950s, people were talking about electroluminescence the way we talk about OLEDs today," Duggal said. "It's humbling."

Gareth has been part of the consumer technology world in a career spanning three decades. He started life as a staff writer on the fledgling TechRadar, and has grew with the site (primarily as phones, tablets and wearables editor) until becoming Global Editor in Chief in 2018. Gareth has written over 4,000 articles for TechRadar, has contributed expert insight to a number of other publications, chaired panels on zeitgeist technologies, presented at the Gadget Show Live as well as representing the brand on TV and radio for multiple channels including Sky, BBC, ITV and Al-Jazeera. Passionate about fitness, he can bore anyone rigid about stress management, sleep tracking, heart rate variance as well as bemoaning something about the latest iPhone, Galaxy or OLED TV.