Turning polluting CO2 into nanotube wool could be a big-bucks green business

You could even make a t-shirt out of it

When life gives you lemons, make lemonade. But what happens when life gives you carbon dioxide emissions? Chemists at George Washington University say: "Make carbon nanotube wool".

A team of researchers led by Stuart Licht have a vision for turning CO2 emissions from a pollutant into a valuable resource, and perhaps even a substantial business opportunity. In a study just published in Materials Today Energy, they described how CO2 sucked out of the atmosphere can be combined with solar energy to produce large amounts of carbon-nanotube (CNT) wool.

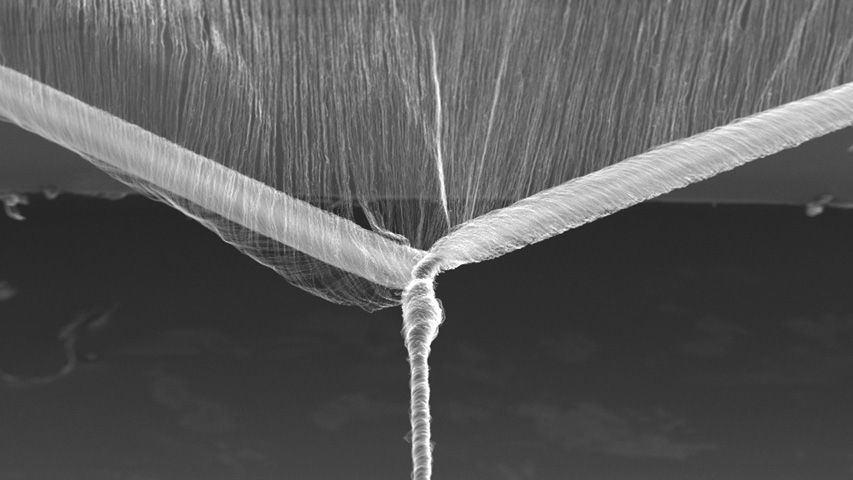

What's that? Glad you asked. It's millimetre-length fibres that can be woven into textiles to make metals, cement replacements and other things. The production process can be done at a cost of $660 per tonne, the researchers say. But the market value of the substance is currently between $100,000 and $400,000 per tonne.

"We have introduced a new class of materials called 'Carbon Nanotube Wool,' which are the first CNTs that can be directly woven into a cloth, as they are of macroscopic length and are cheap to produce," Licht told Phys.org. "The sole reactant to produce the CNT wools is the greenhouse gas carbon dioxide."

Strength-to-mass

The team has been working on the process since about 2010. Previously, they were only able to create very short-length nanotubes - less than 100 micrometres long, which can't be woven.

They solved that problem by replacing a key component made of copper or steel with one made of Monel - a nickel-copper alloy. With subsequent tuning, they were then able to produce much longer fibres.

"Inexpensive, weavable CNT wools are preferred replacements for conventional steel and aluminum applications, due to the CNT wool's lightweight, strength-to-mass advantage," Licht said.

Sign up for breaking news, reviews, opinion, top tech deals, and more.

"In addition to textiles, CNT wools serve as preferred additives to formulate blast- and fracture-resistant cement and ceramics. Other applications of stronger-than-steel, highly conductive CNT cloth are bullet-proof CNT suits and taser-proof suits."