Fuji chooses humans over robots

Fuji cameras and lenses are made by actual people rather than machines

Fuji's human assembly line

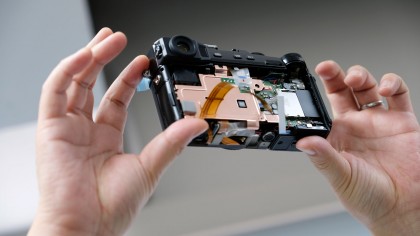

When you imagine an assembly line in a factory in Japan you probably think conveyer belts, robots and automated processes. That's certainly what I had in mind as I entered Fujifilm's Taiwa factory in Sendai, Japan last week, but I soon realised my mistake. Instead of robots, Fuji relies on a highly skilled workforce armed with powered screwdrivers, soldering irons and a variety of forceps to handle the many tiny components in its cameras and lenses.

Rigorous quality control

This approach imbues quality and craftsmanship, but what about human error? Fuji uses an intensive checking process to verify button, viewfinder and firmware performance as well as ensuring that picture quality is up to scratch by shooting (top-secret) test charts and analysing images. Even then, 10% of the boxed up cameras are unboxed again and checked to make sure everything is present and correct.

Fuji X-T1 assembly

Fuji assembles its X100T, X-T1 and X-Pro2 cameras in the Taiwa factory, as well as a collection of lenses. I was taken on a tour of the X-Pro2, X-T1, XF35mm f/2 R WR and XF100-400mm f/4.5-5.6 R LM OIS WR assembly lines, and allowed to photograph most steps of the assembly process – but not the testing procedures.

Zero contamination clothing

While the workers in the camera assembly areas wear the white coats, gloves and masks typical of a cleanroom environment, hairnets/hats are not a requirement, and visitors are able to wear normal clothes. The lens assembly areas are different, though. Here, everyone is required to wear full cleanroom outfits including a hairnet, hood, overall, boots and mask. Gloves must also be carefully pulled over sleeve ends to contain as much dust and fibre as possible. It's a hot and stuffy get-up that I was very pleased to remove after just an hour, so hats (or hairnets) off to the workers who wear it all day every day.

Humans vs robots

Entry to the lens assembly area is via a series of blower/vacuum systems before gloved hands are washed – and there's an extractor system to remove any dust that should drift free. It would presumably be easier to keep dust levels down if robots were used, but they're less flexible than humans, who can be assigned new tasks as required.

The finished product

Fuji's workforce also seems as efficient as robots. Modern high-performance lenses are fiendishly complex, but it takes just 80 minutes to put together a 35mm f/2 lens, and three hours to build a 100-400mm lens from component parts produced in Fuji's other factories. It's an impressive set-up, and the workers' dedication is clear to anyone who visits. And if you're admiring the quality of these photographs, they were taken with a pre-production Fuji X-Pro2.

Sign up for breaking news, reviews, opinion, top tech deals, and more.

You are now subscribed

Your newsletter sign-up was successful