This new battery concept could give electric cars a 1000km range

By stacking cells on top of each other

Sign up for breaking news, reviews, opinion, top tech deals, and more.

You are now subscribed

Your newsletter sign-up was successful

One of the biggest challenges when designing an electric car is where to put the batteries.

Every vehicle has hundreds to thousands of separate battery cells, each surrounded by a housing and connected to the car systems and sensors. This complex design takes up space - more than 50 percent of the area dedicated to batteries inside the car is taken up with housing and contacts.

But now a team of engineers at the Fraunhofer Institute for Ceramic Technologies and Systems (IKTS) has developed a new battery concept that could substantially decrease the amount of space needed for housing and contacts - meaning more batteries can fit in the same car.

Their system stacks battery cells directly one above the other across a large area, as opposed to the traditional approach where individual cells are strung side-by-side in small sections. The direct connection to each cell in the stack allows current to flow over the entire surface of the battery, significantly reducing electrical resistance.

"With our new packaging concept, we hope to increase the range of electric cars in the medium term up to 1000 kilometers," said Mareike Wolter, Project Manager at Fraunhofer IKTS.

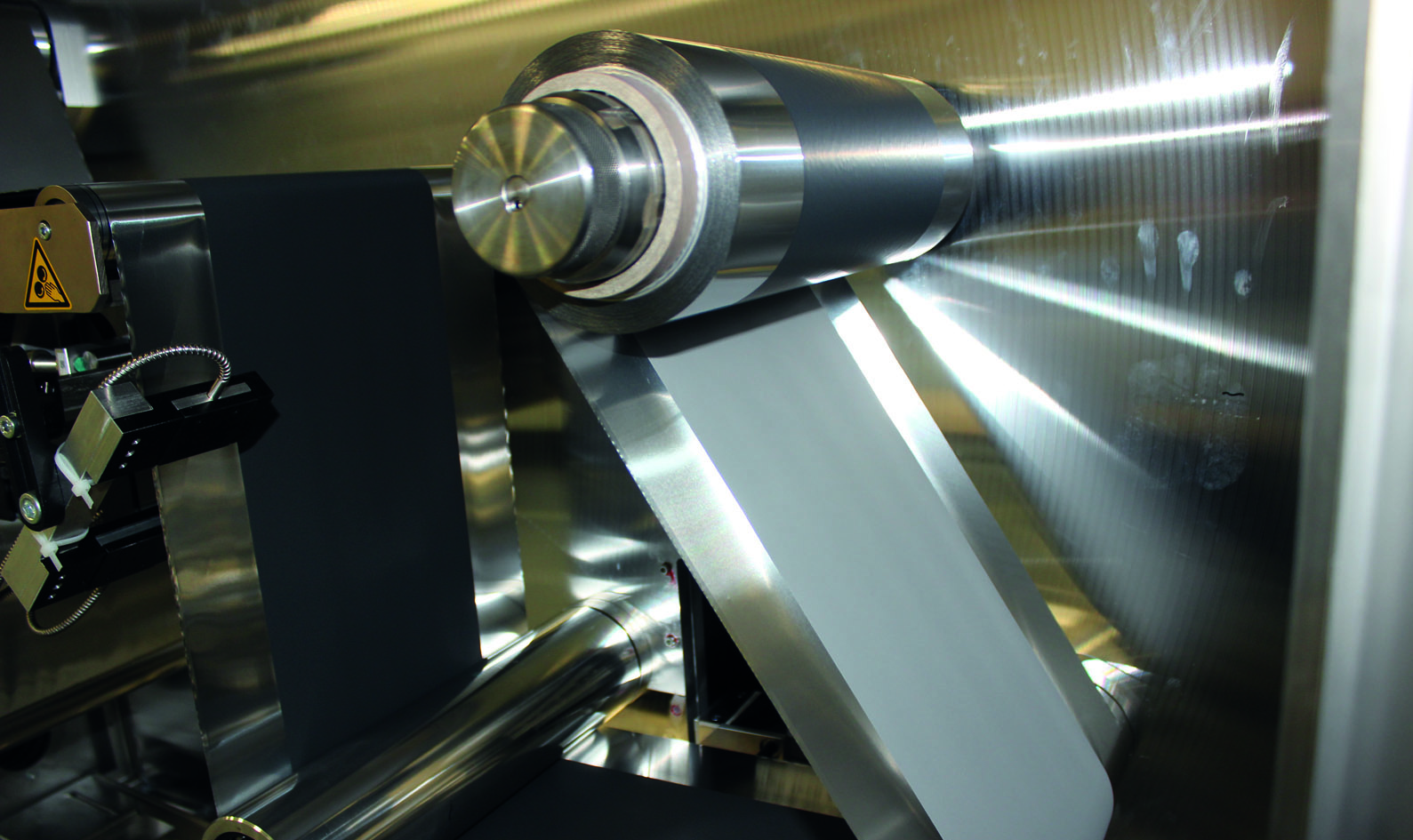

Metallic tape

The key to being able to do this is a new electrode - in this case, a metallic tape coated on both sides with ceramic storage materials. One side is the battery's anode - the other is the cathode.

Developing each material is a complex process, involving a suspension of powdered ceramics mixed with polymers and electrically conductive materials.

Sign up for breaking news, reviews, opinion, top tech deals, and more.

"We use our expertise in ceramic technologies to design the electrodes in such a way that they need as little space as possible, save a lot of energy, are easy to manufacture and have a long life," said Wolter.

The research is still a work-in-progress right now, but the concept is being scaled up to larger battery cells which can be installed in real electric cars. Initial tests are due for 2020, but Wolter is optimistic that this should take place without difficulties:

"One of the core competencies of our institute is to adapt ceramic materials from the laboratory to a pilot scale and to reproduce them reliably," she said.