I reviewed more than 50 of the best 3D printers of 2025 but these are the top 9 I recommend

I tested more than 50 of the best 3D printers for modeling, miniatures, crafting, prototyping, and more

Sign up for breaking news, reviews, opinion, top tech deals, and more.

You are now subscribed

Your newsletter sign-up was successful

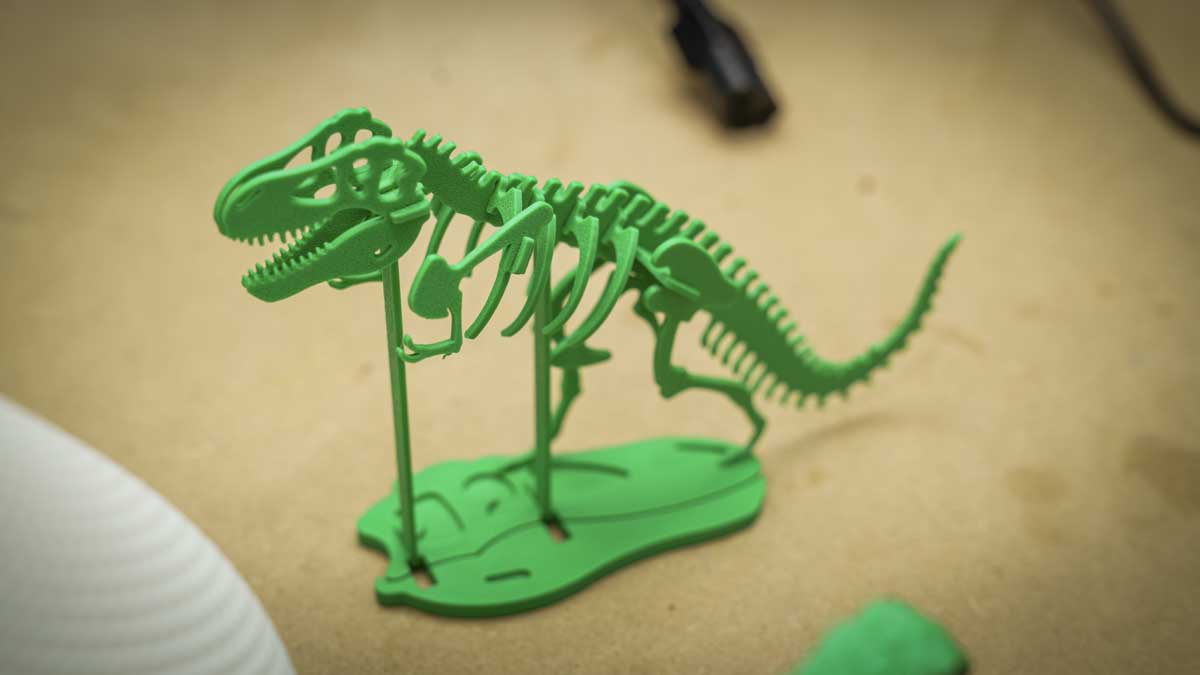

Having tested over 50 of the best 3D printers so far (and counting), I'm very excited to see what else 2026 will bring in this field. When it comes to precision printing, there's so much choice around now - from cheap 3D printers to professional-grade units fit fit for any business - all delivering accuracy and fast print speeds at every budget.

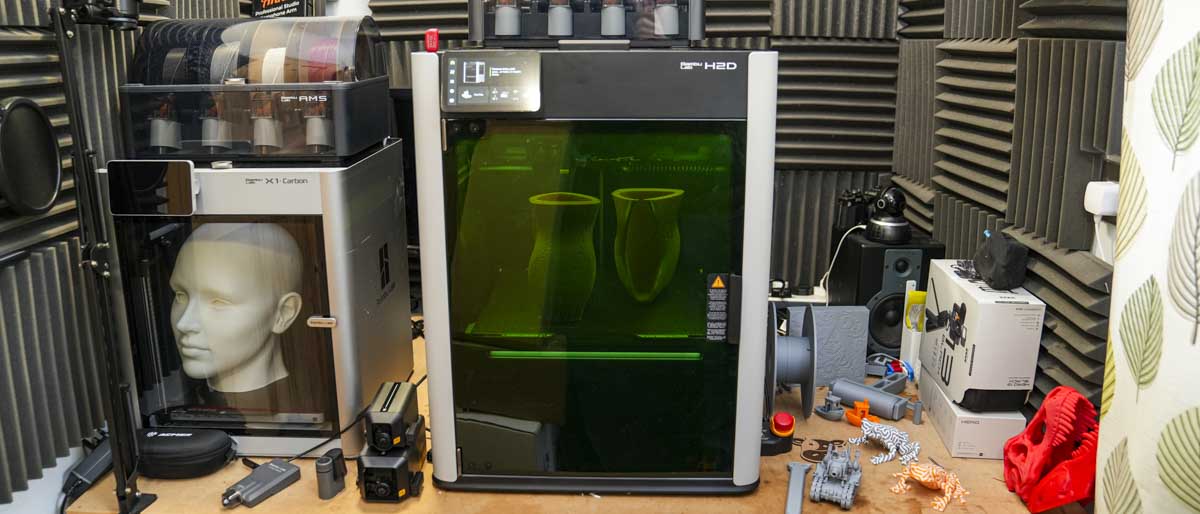

Based on testing in my workshop, the Bambu Lab H2D is one of the best I've ever tested. I think most users will love the speed, performance, and quality of the output. If you're a creator or crafter, then check out the 4-in-1 version, which includes a laser cutter, engraver, and digital plotter. As a multi-function 3D printer, it's the best of its kind I've ever used right now.

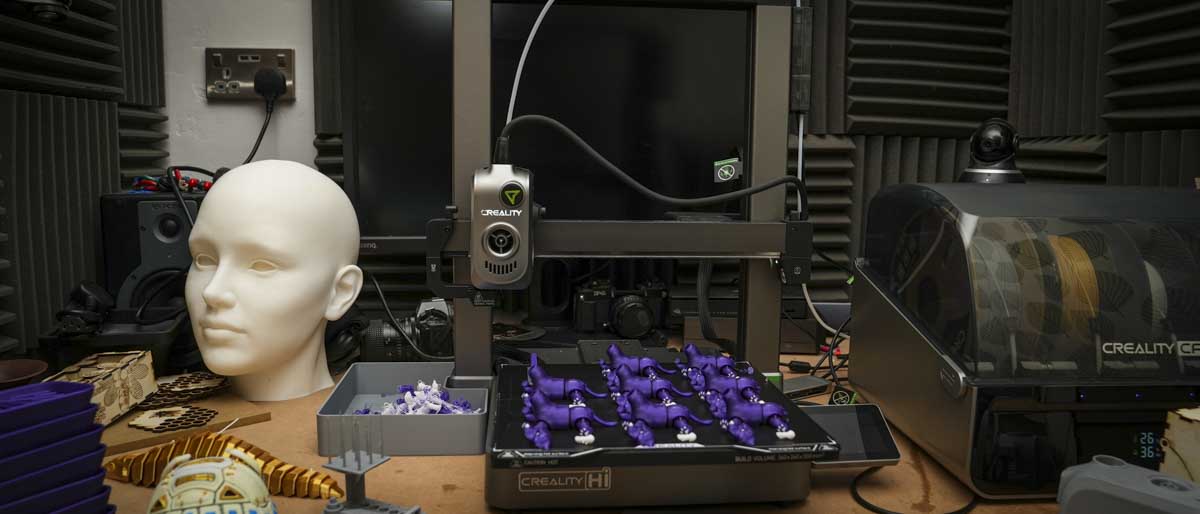

If you're new to 3D printing, though, you can't go wrong with the Creality Hi. I found this unit fast, fun, impressively accurate, and one of the best cheap 3D printers (and one of the best hobby 3D printers) you can buy. Check out the reviews below for the full benchmark test results - I've tested all these models personally, measuring design, speed, and precision in my studio. This will help you see how the units compare and why I recommend these 3D printers to everyone.

What's new? Since my last update, I've reviewed the Original Prusa Core One L, Bambu Lab H2C, and Piocreat Halot-X1. All three impressed me for performance, scoring 4.5 stars. Well worth exploring if the 3D printers below aren't quite what you're looking for.

The quick list

The H2D combines three machines in one with a modular design that enables you to 3D print, laser engrave and cut, although not all at the same time. It's compact, easy to use, and packed with creative features, making it a good all-in-one choice for enthusiasts and professionals.

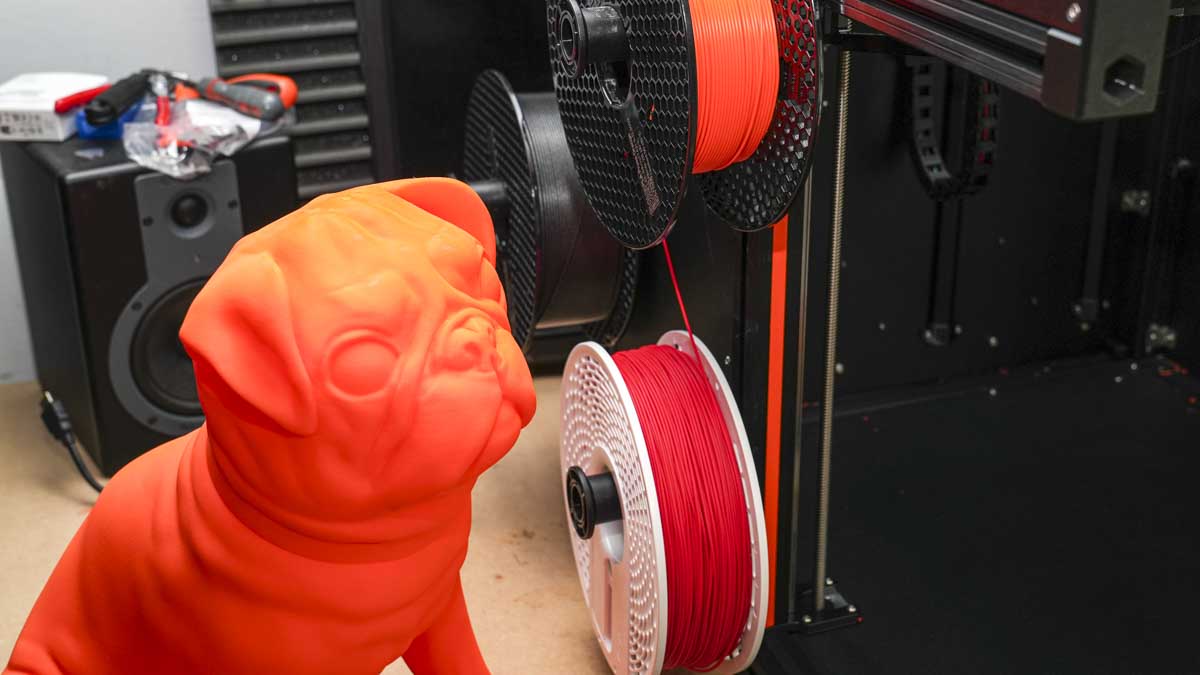

The Creality Hi offers an outstanding, easy-to-use, multifilament 3D printer for cheap. The build is sturdy and it includes all the features you could wish for, such as touchscreen, auto-levelling, built-in camera, and the ability to print up to 4 colors out of the box, making it fun and surprisingly versatile.

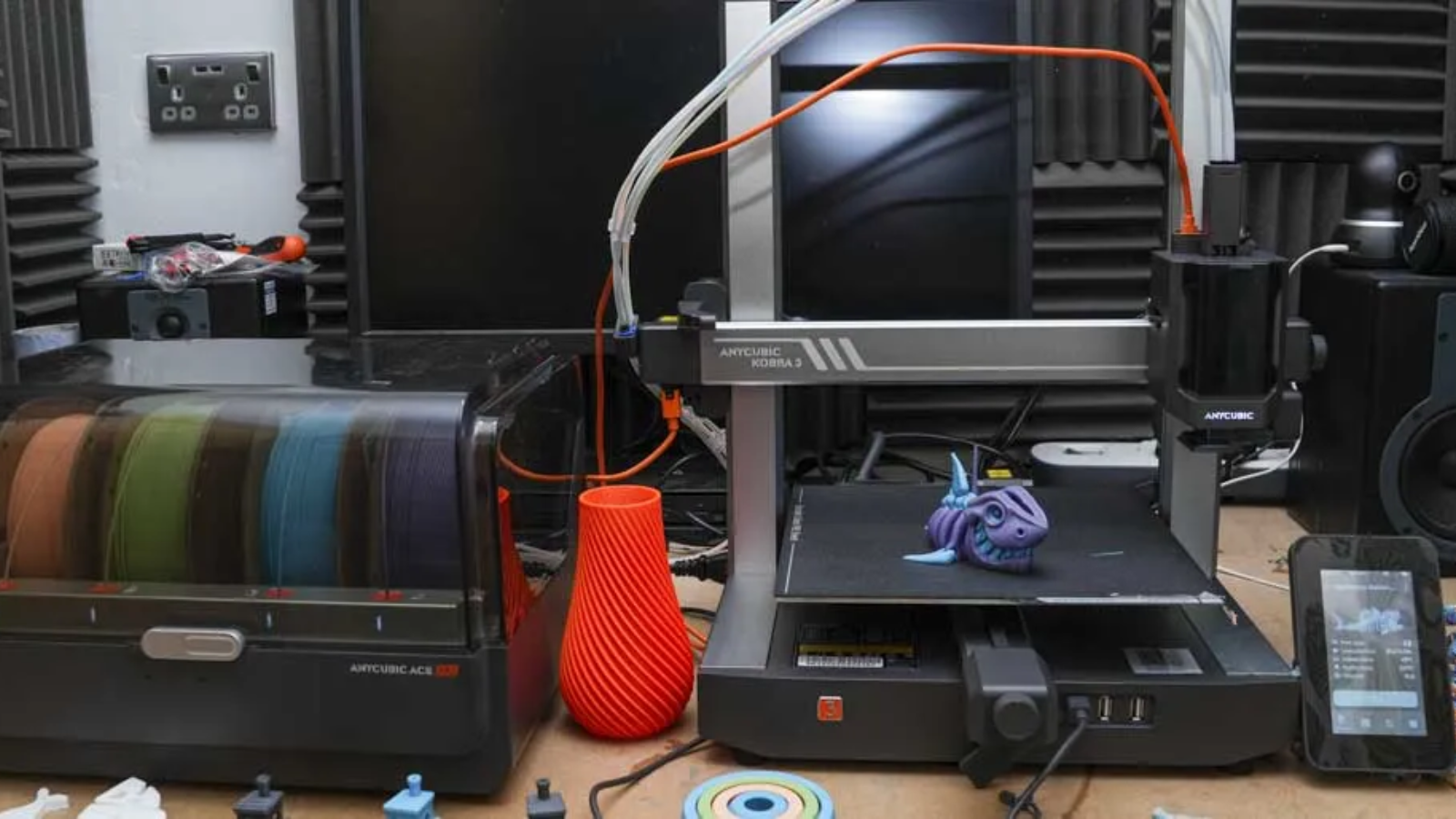

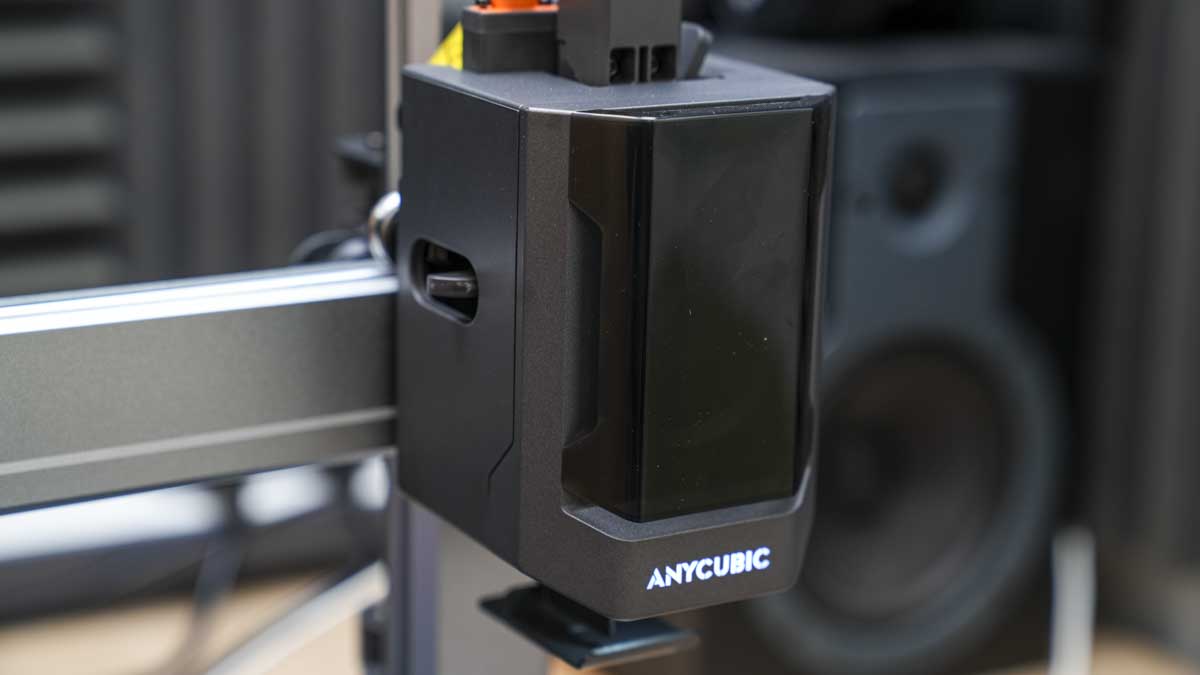

The Kobra 3 Combo is great for beginners and hobbyists wanting multifilament printing. The machine is extremely user-friendly, fast, and through my test and use beyond the review has proven reliable, with an easy workflow that supports up to 4-colour printing.

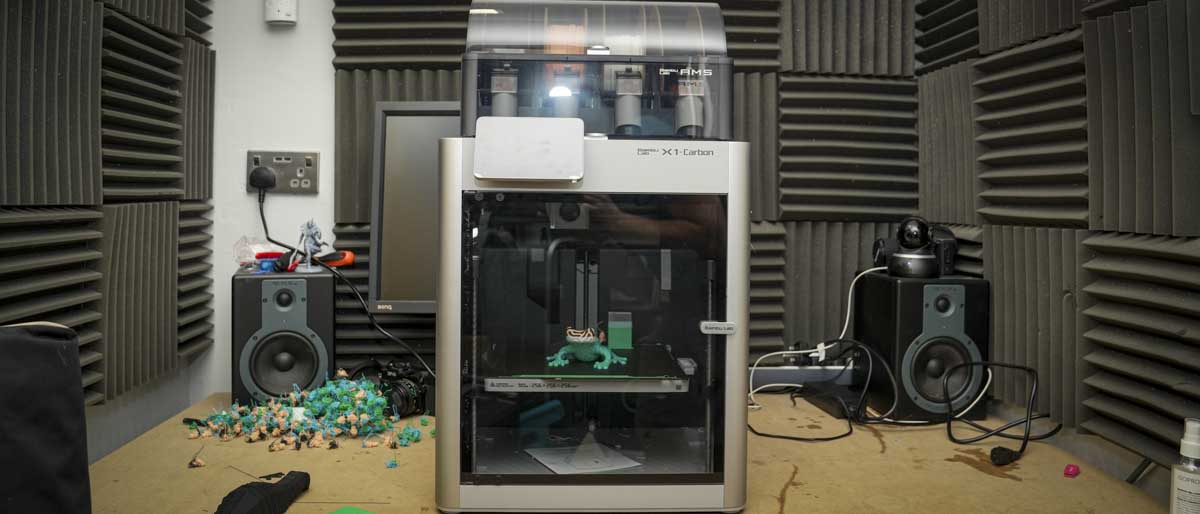

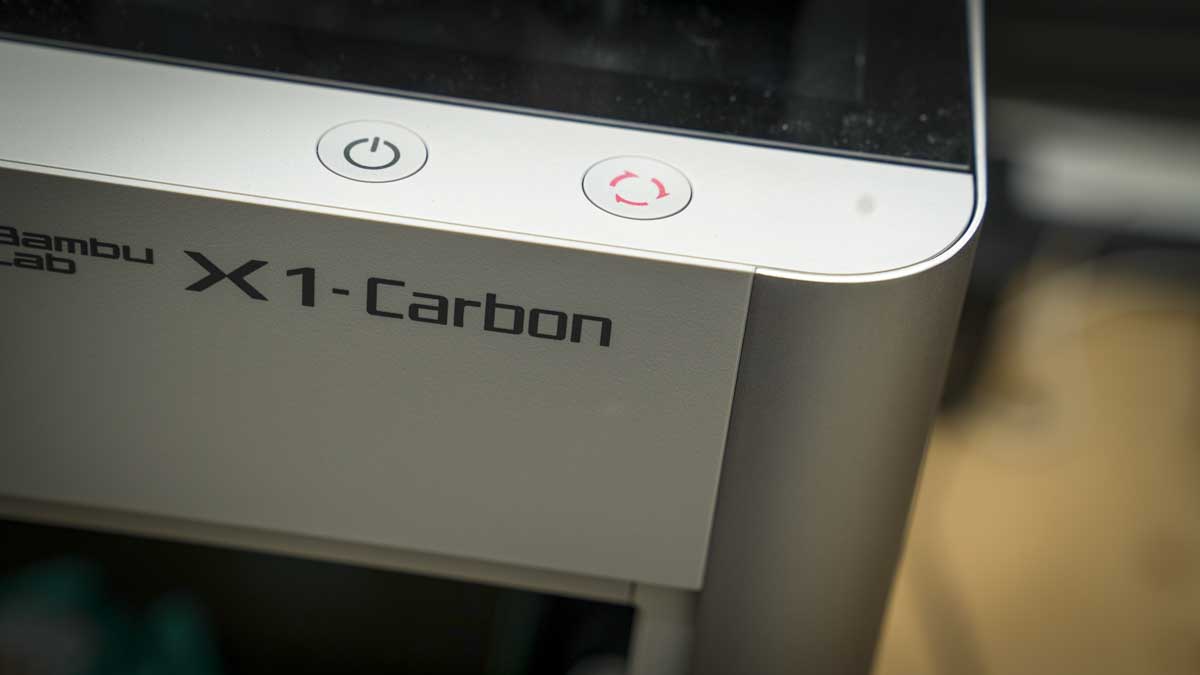

The X1C is a benchmark machine that delivers rapid, high-precision multifilament prints with minimal fuss. There's a reason for the popularity of this machine: it's simply reliable, easy to operate, and ideal for educational establishments where speed, quality and consistency are essential.

This is the question I get asked most: What 3D printer to buy for my business? Only the Prusa Core One offers that combination of professional-grade print quality, enclosed CoreXY mechanics and reliability. It's also fully serviceable and you can expand it in any way you like, in a way no other machine can come close to.

Designed with precision and large-scale prints in mind, the fully enclosed CoreXY frame, heated chamber, and hardened 370 °C hotend are capable of delivering accuracy and reliability, making it an ideal fit for design studios and prototyping.

Load the next products...

The Original Prusa XL is an uncompromisingly large 3D printer that's more than capable of tackling large-scale 3D printing for engineering projects and more.

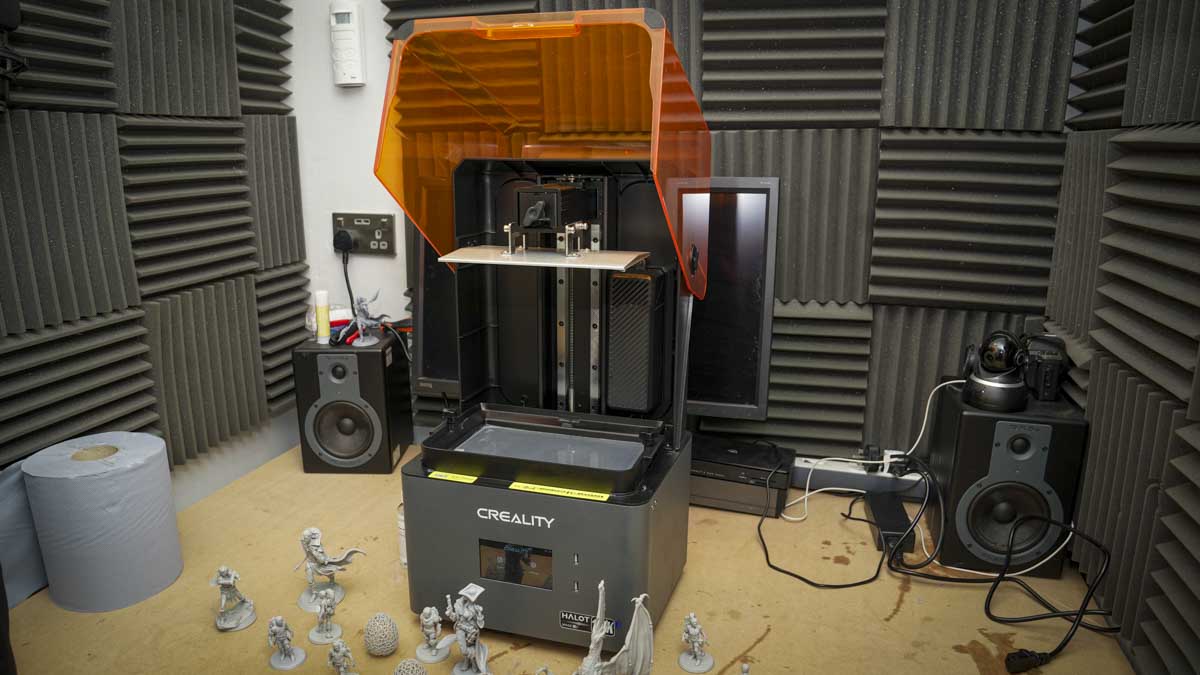

With its 14K resolution, precise prints, and high-quality output, the Creality Halot-Mage S is perfect for 3D printing miniatures for tabletop gaming and similar.

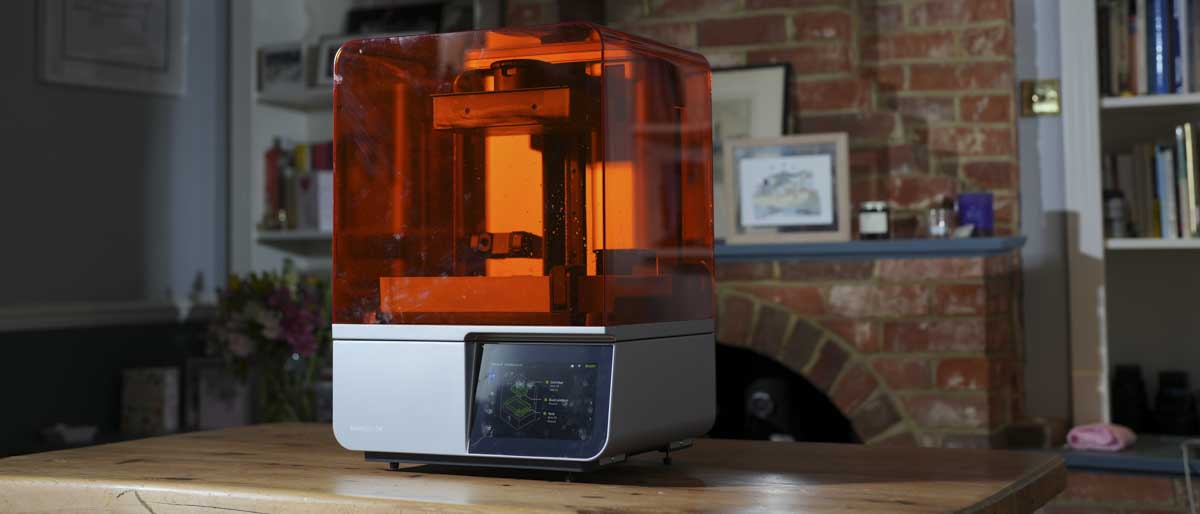

The Formlabs Form 4 easily bridges that elusive gap between mass-scale injection moulding and 3D printing - and it does it with style. Ideal for small production runs.

Best 3D printer overall

Specifications

Reasons to buy

Reasons to avoid

✅ You want a 3D printer and laser cutting unit

✅ You want high-quality prints at speed

❌ You need a single-filament 3D printer

❌ You just want a 3D printer without the extra features (or you just want a laser cutter)

The H2D Full laser Combo is a bit outside of the usual mainstream 3D printing machine, as essentially it features a range of tool heads for different functions, including laser engraving, cutting, and digital cutting. Those tools aside, the 3D printing heart of this machine is still exceptional, and while there are some quirks, the fact that it offers five filament printing out of the box, with the option to print up to 16 with a few additions, makes it stand out.

The H2D comes in two versions, the straight 3D print and the full laser combo which the straight 3D print version can be upgraded to. Both are multi-material print ready and offer a large build volume with a dual nozzle hotend system that helps dramatically speed up dual filament printing and, to a degree, helps to reduce multifilament print times as well. The dual nozzle also dramatically reduces filament waste for multi-colour or multi-material prints, helping you to save money.

One of the big benefits of the H2D is its heated chamber and all-metal hotend, ensuring that it can handle complex models and more demanding filaments such as ABS and ASA. Through the test, the print quality was consistent, with the kind of precision you'd expect from a commercial unit.

Having the option to swap tool heads means that the H2D is packed with creative potential, making it a great choice if you want to experiment across a range of different media and disciplines, all without needing several separate machines.

There are, of course, a few downsides to the H2D, in as far as it does weild a higher price point than many other enthusiast printers, and the various add-ons, such as the laser and AMS units, will require a bit of workspace and organisation. Personally, I found switching between toolheads to be intuitive once I'd done it a few times, and even storing all the extra modules and build plates when organised was relatively simple.

The H2D earns its place as "Best Overall" because it combines superb 3D printing with genuine multifunction creativity in a single machine.

Read our full Bambu Lab H2D 4-in-1 3D printer review

Best 3D printer on a budget

Specifications

Reasons to buy

Reasons to avoid

✅ You want a cheap and reliable multi-filament 3D printer

✅ You want a unit that's really easy to use

❌ You need dimensional accuracy for product design

❌ You require fast multicolor printing

When I tested the Creality Hi, I had to recheck the price as it was difficult to mentally balance the price of the machine with the quality of the output. Since my review, this printer has become a firm favourite, and a regular recommendation for multi-colour prints for anyone wanting to get started with multifilament printing.

The base machine is quick to construct with a solid chassis, responsive touchscreen, auto-levelling bed and built-in camera, all features that are rarely seen at this price point. Out of the box, it also supports up to four colors via its Multifilament System (MFS), making it ideal for hobbyists or crafters looking to create complex models without fuss.

In use, the Hi impresses from the start with consistent print quality, and a heated bed that provides an impressive level of adhesion, ensuring that prints large and small stay put and secure. Other print characteristics such as bridging and overhangs all hold up well. The small camera enables you to remotely monitor prints through the Creality print software, and while it's not as advanced as some, it's still a great addition.

The touchscreen control makes menu navigation easy, and Creality's UI is well thought out and easy to navigate. Most of the more complex setup is handled by the machine with auto-levelling, removing the need for tedious manual adjustments during the setup process and first print.

While the Hi is a remarkable machine, it isn't without its limitations. The Hi handles four-colour jobs well, but dimensional accuracy can slip slightly compared to pricier models, especially on very fine details. It's also worth noting that the open frame design also limits the materials that can be used, and really, this is a machine optimised for the use of PLA.

Then there's the subject of filament changes where waste quickly builds up when materials swap out. Another point is that while I'm a bit of a fan of the build plate adhesion strength, some might find removing models a little tricky, especially if they're small and delicate.

From personal experience, the Hi offers a consistent performance and good range of features that make it a go-to for fun, multi-colour creations that ordinary single-filament printers can't match. Despite being very affordable, it's still able to deliver a surprising feature set and a build quality that only a couple of years ago would have been considered decidedly premium. If you're looking to get creative with color, then the Creality Hi is hard to beat at its price.

Read our full Creality Hi 3D printer review

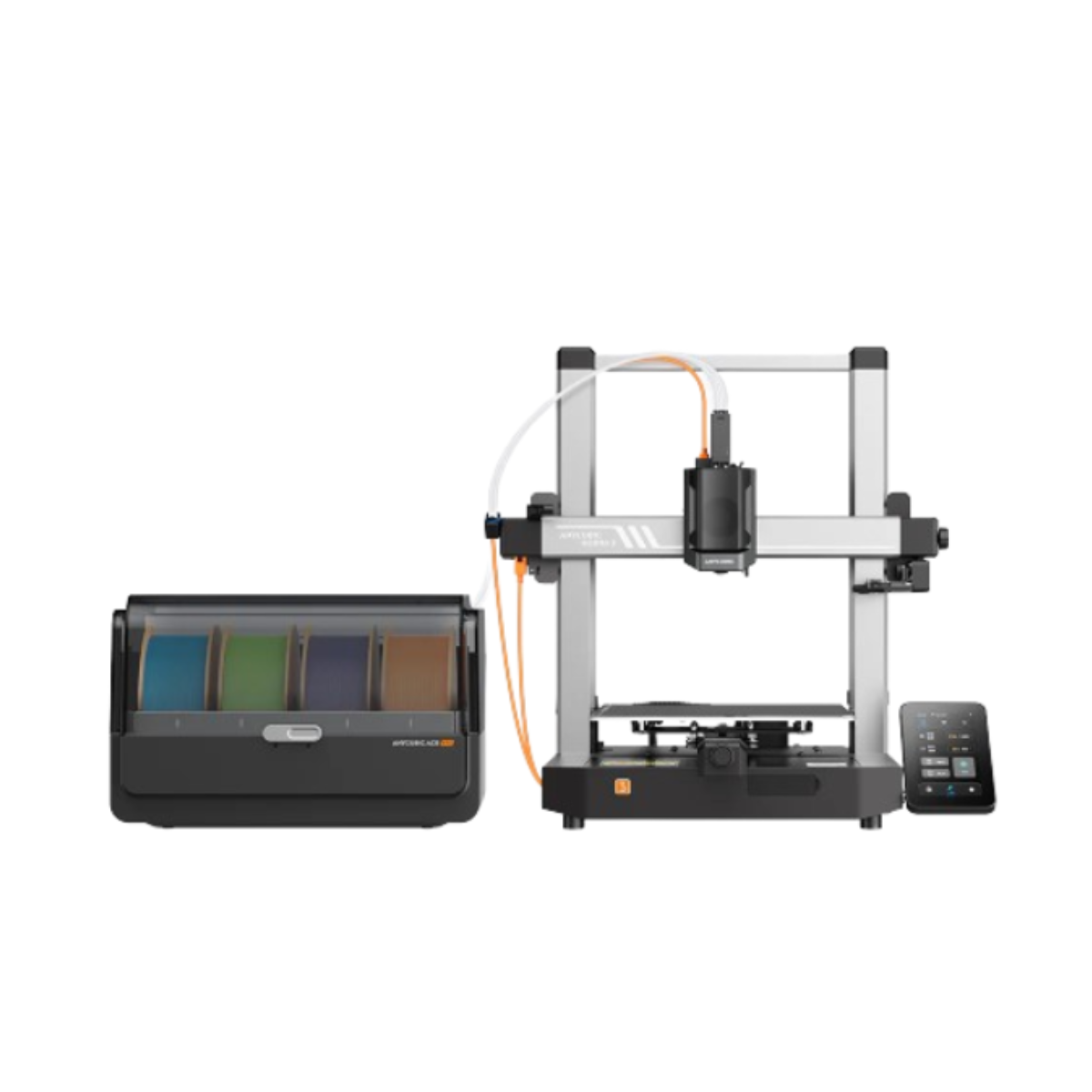

Best 3D printer for beginners

Specifications

Reasons to buy

Reasons to avoid

✅ You want an entry-level multifilament machine

✅ You want a machine that's reliable and easy to use

❌ You need a fast multifilament machine

❌ You want to use this for education

This 3D printer is an ideal choice for any individual or business looking for an intuitive, compact, and beginner-friendly machine that provides the performance and accuracy to grow with your skills. Having used a variety of iterations of the Anycubic machines, I've found that they are always reliable once set up, and the Anycubic Multifilament ACE Pro system now enables easy multi-colour printing that will appeal to all levels of users.

The Kobra 3 Combo's build quality impresses with a sturdy frame, and clear instructions are included for every step of the construction before the intuitive touchscreen guides you through the mainly automatic calibration.

From the first print, auto-levelling proves to be accurate and remains consistent, even after months of use. I particularly like the ACE Pro, Anycubic's multifilament unit, and while it requires its own power source, rather than drawing from the printer, it does simplify material changes and colour transitions, enabling an almost ready-to-go out-of-the-box four-colour print solution.

Print quality is generally good with minimal ridging, overhangs look straight, and supporting structures are able to be removed with relative ease. Though it's not as precise as ultra-high-end CoreXY machines, it does result in decent quality prints, making it ideal for simple figurines, props, prototypes, and much more. One of the features that I liked was the flexibility over the speed settings that were easy to understand and balanced between quality and printing time without fuss.

On the downside, switching between materials in the Ace Pro creates some material waste during colour changes, but this is in line with most other models of the type. Build volume is also modest, at 250 × 250 × 260 mm, so while it's not suitable for very large models, it should suit the needs of most beginners.

As a beginner, support is always valuable and this is where Anycubic really stand out, they have a large and active user community and their tech support is, from my experience, superb with a good range of easy-to-follow online guides.

Since the initial review of the Kobra 3 Combo, the machine has continued to run reliably, producing small to medium-sized props and other larger items. For me, the simple design, easy-to-access user interface and quality of the multifilament box all make this an advanced but seemingly simple machine that does a lot in the background to make your life easier.

Overall, the Anycubic Kobra 3 Combo is ideal for beginners, striking the balance between multifilament printing for creative models and consistency, which means that it just continues to work without fuss.

Read our full Anycubic Kobra 3 Combo review

Save on your next 3D printer with our Anycubic promo codes

Best 3D printer for education

Specifications

Reasons to buy

Reasons to avoid

✅ You want speed, quality, and consistency in the workplace or school

✅ You want reliability and ease of use

❌ You're worried about filament waste - this unit spits it out

❌ You want an entry-level or cheap 3D printer

The Bambu Lab X1 Carbon (or X1C) is a common sight in educational settings and offers a straight forward and fast 3D print solution. In my experience, the AMS system, AI-guided calibration, and enclosed CoreXY build make it a great choice for use in the classroom or lab where consistency and reliability matter. In fact, one is used by the team in the engineering department at Wiltshire College for this very reason.

From the moment it's unboxed, the X1C feels refined with a high level of product design that separates the Bambu Lab printers from the majority of others. The AMS (Automatic Material System) handles up to four filaments, enabling automatic colour and material transitions during a single print. When the accuracy and speed are combined with AI-driven bed probing and calibration, the setup process is generally fast and largely hands-off, ideal when multiple users or classes share one machine.

The enclosed CoreXY design ensures thermal stability, reducing warping and maintaining consistent print quality across long sessions and also enables lecturers and students to experiment with advanced materials such as ASA and Nylon.

Prints come out accurate with sharp edges, even on intricate models, and the ability to add support material alongside different coloured filaments all adds to the potential of what you can print and create.

The machine is based on Core XY, ensuring impressive speed, meaning that simple single filament prints finish faster than many budget alternatives without sacrificing finish quality. Multifilament prints are slower and, like most multifilament options, there is the waste to contend with.

Still, the X1 Carbon's workflow and straightforward touchscreen combined with remote monitoring means that as a lecturer, teacher, student, or lab technician you can focus on the class rather than watching the machine. That reliability and ease of use are what make it stand out in an education environment, where printers must "just work," or sit there gathering dust.

That said, the X1C isn't perfect; the build volume is limited at 256 × 256 × 256 mm, so larger projects will need to be split into parts. Then there's the AMS system, which, while brilliant, does add cost and some complexity for maintenance compared to simpler single-filament machines, and spare part replacement (e.g. filament drive modules) can be pricier.

Having the X1C running most of the time I can confirm it wins on consistency, students get a quality print to learn from, and downtime is minimal. It's fast, reliable, and smart, everything a school or university needs. That's why the X1C is my choice for the "Best for Education" category.

Read our full Bambu Lab X1C review

Best 3D printer for business

Specifications

Reasons to buy

Reasons to avoid

✅ You want one of the best 3D printers ever made

✅ You want pro-grade 3D printing results

❌ You're a complete beginner

❌ You're working to a budget

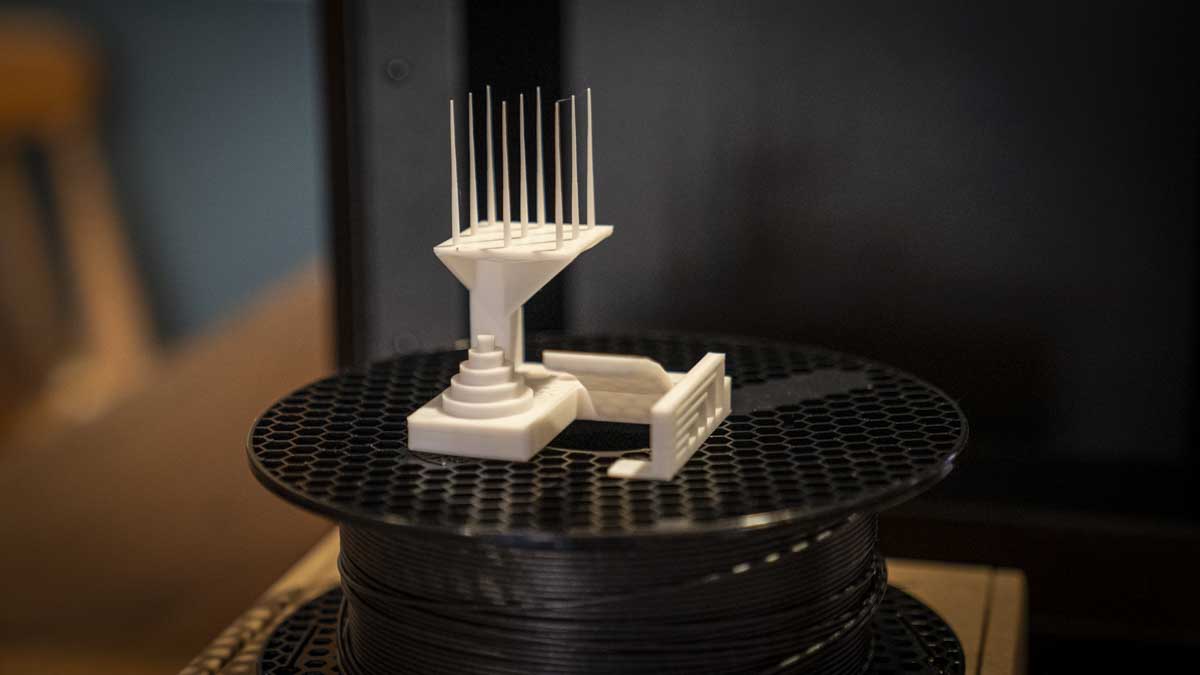

The Original Prusa Core One stands out for businesses for its professional-grade reliability, ease of integration into larger systems, and of course the pure speed and quality of the prints. In my experience, it delivers the best print quality you can get from an FDM printer, with excellent mechanical stability, and a workflow that enables you to adapt and add to the printer to suit the needs of your business.

From setup to first layer, the Core One feels different, and its enclosed CoreXY architecture and all-metal build add to the feeling of robustness, making it ideal for prolonged, production-style use with minimal supervision. The integration with PrusaSlicer and Prusa Connect also enables an easy way to centralise management for print jobs, which in my case means that I have a CORE One and a MK4 and MK4s all running and controlled and monitored from the same system. This makes it a fit for small businesses or prototyping labs.

In terms of print quality, the 3D printer can be summed up as consistent and will produce a similar quality of model from a range of materials; from PLA to engineering components with ASA. As I've seen with the latest advanced printers, the CORE One features automatic bed levelling, filament sensors, and advanced extruder calibration, and while it doesn't have AI cameras and monitoring as standard, from experience it just doesn't seem to need it as the room fault is minimal. I've used this model extensively, and it's the one that remains in the office rather than the workshop, always ready to go.

That said, as ever, it's not without limitations. Its build volume (250 × 220 × 270 mm) is smaller than some industrial-grade competitors, potentially requiring staged or split prints for larger items. Maintenance spare parts can be pricey, and the upfront price is higher than entry-level machines, though justified by dependability and ecosystem support and now cheaper than some of the competitors.

In daily use, the Core One has rarely faltered, switching between materials, managing print queues, and handling repeated stress without issue. Its predictable performance and integration-friendly software make it a great solution in the long run. The one other aspect to consider is that the MMU3, which is the multifilament attachment, is yet to be released, but once it arrives, there will be few other printers that will be able to match the Core One, making it my choice for business-use.

Read our full Prusa Core One 3D printer review

Best 3D printer for precision

Specifications

Reasons to buy

Reasons to avoid

✅ You're printing with high-temperature materials

✅ You want a precise, accurate, and durable 3D printer

❌ You want a 3D printer with AI features

❌ You're likely to get frustrated by the laggy interface

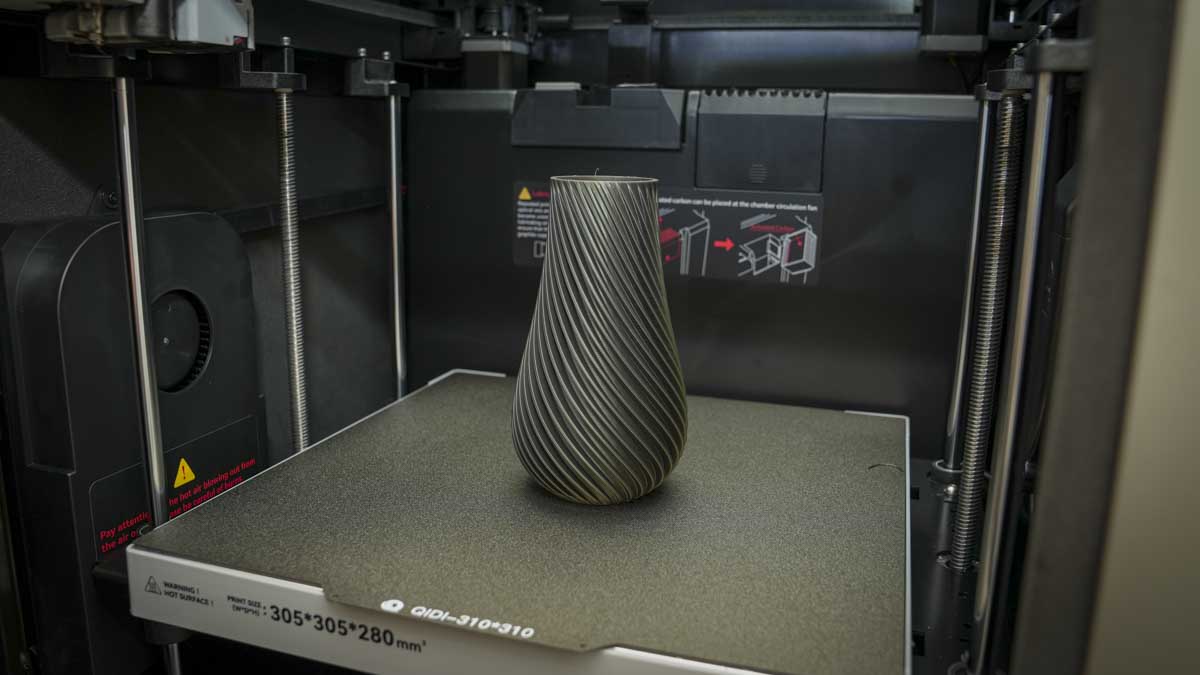

The QIDI Plus4 is a great machine when precision matters most and you don't need multifilament printing. The fully enclosed CoreXY frame, heated chamber, and hardened 370 °C hotend offer plenty of material flexibility and the Plus4 proved to consistently deliver exceptionally accurate results, even when going large.

Right from the initial point of setup, the Plus4 feels built for purpose. It features a solid frame with a large build area (305 × 305 × 280 mm), giving you plenty of room for larger prototypes or multi-part prints. With a heated chamber and high-temp hotend, it handles technical filaments well, including ABS, ASA, polycarbonate, and advanced engineering materials, without warping.

Throughout my tests, it was the Plus4's print precision that was the machine's core strength. In real-world projects, fine-detailed parts come out clean and with fine detail. Dimensional accuracy was excellent, and this was shown with the brackets that we printed during the initial testing, as well as in the main benchmarking tests. This accuracy makes the Plus4 a great option for prototyping, engineering models, and small-batch production where parts must fit and function accurately together.

The workflow is also business-ready with solid and user-friendly slicer software, which whilst not as aesthetically designed as some is still impressive and intuitive. The touch screen user interface, robust slicing options, and filament sensors proved that errors were few and far between, with most initiated through user error rather than by the machine or mechanics.

Of course, high precision comes with trade-offs. It's pricier than hobbyist models, and while this is justified by its feature set and consistency, it is a heavy machine, so not one that you would want to move once in position. Unlike some of the more consumer-level machines, the initial calibration does require care, and maintenance (such as chamber cleaning or module replacement) is more involved than on those simpler printers.

Despite this, the QIDI Plus4's precision and build quality are reflected in the quality of the prints. If precision is key to your use of a 3D printer, then this is a solid investment.

Read our QIDI Plus4 3D printer review

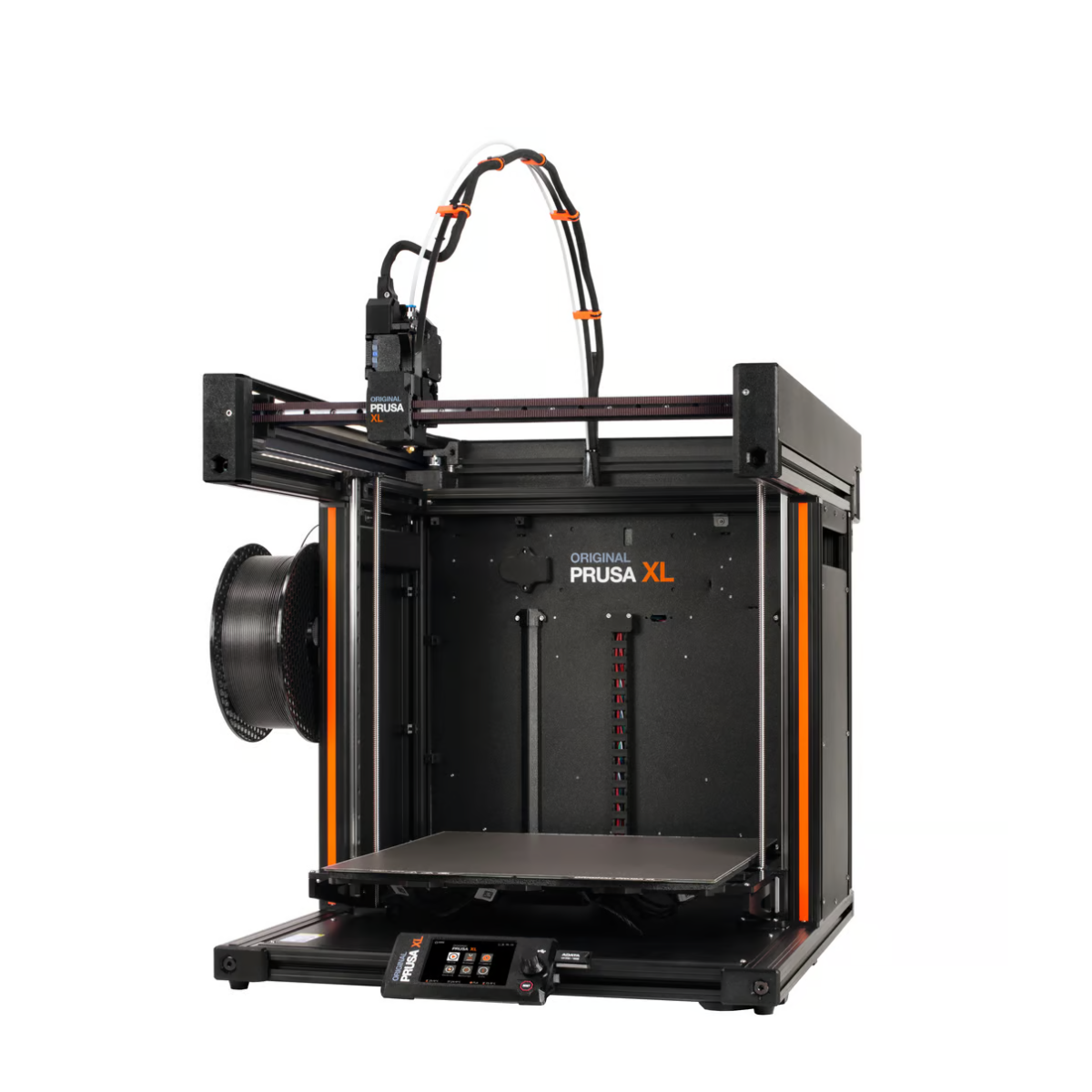

Best 3D printer for engineering

Specifications

Reasons to buy

Reasons to avoid

✅ You want one of the fastest multifilament printers out there

✅ You need to print large scale models quickly

❌ You have limited space - this unit is a beast

❌ You're new to 3D printing or you budget is limited

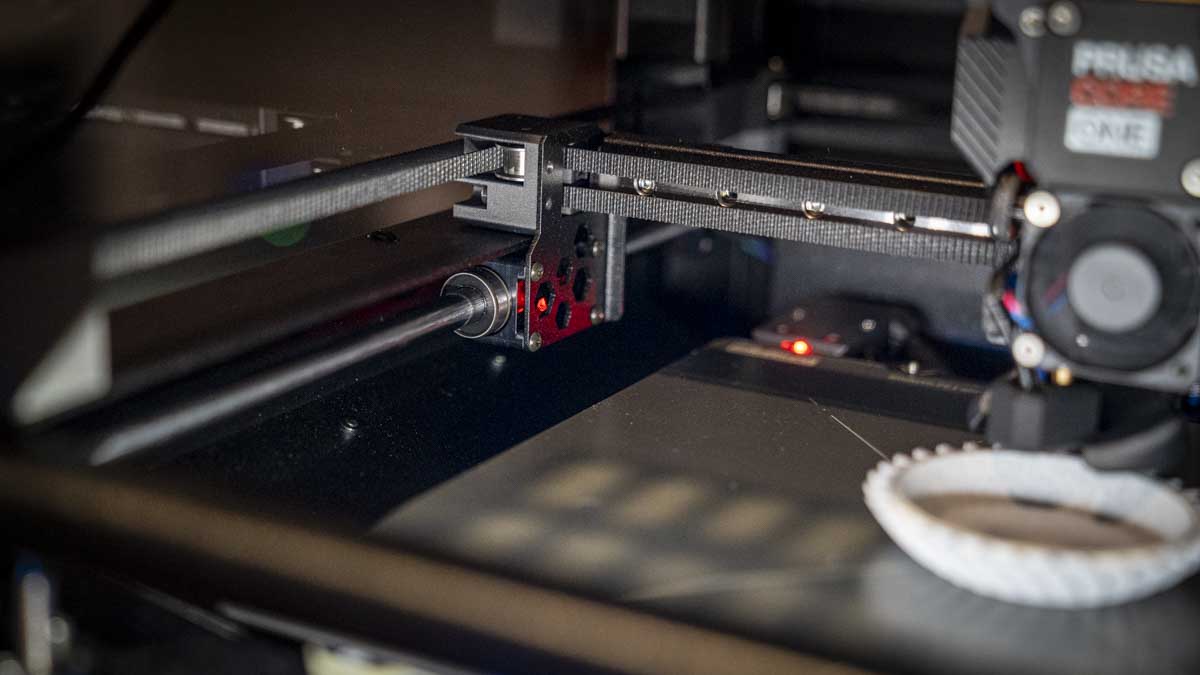

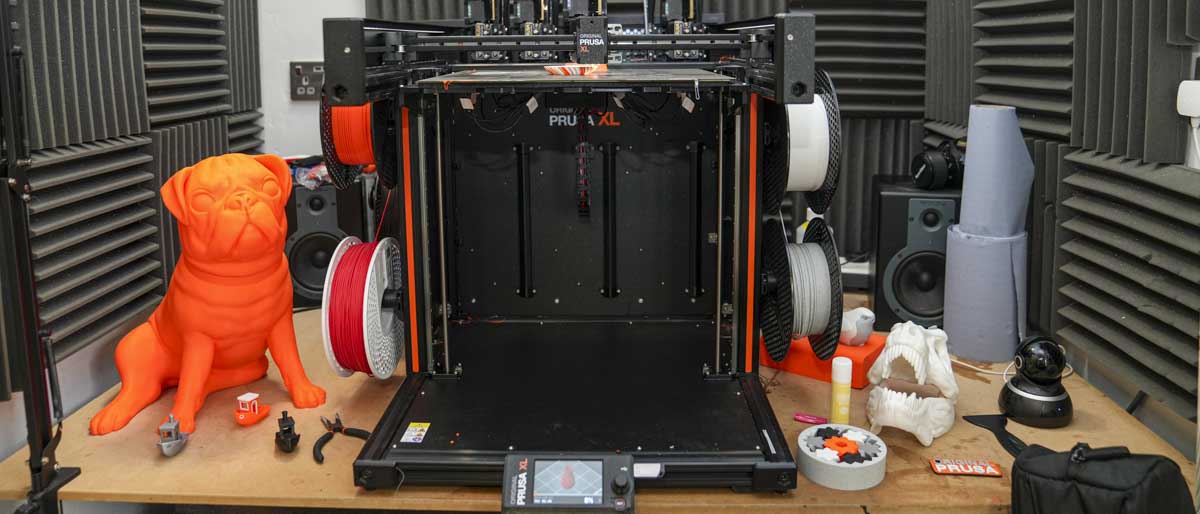

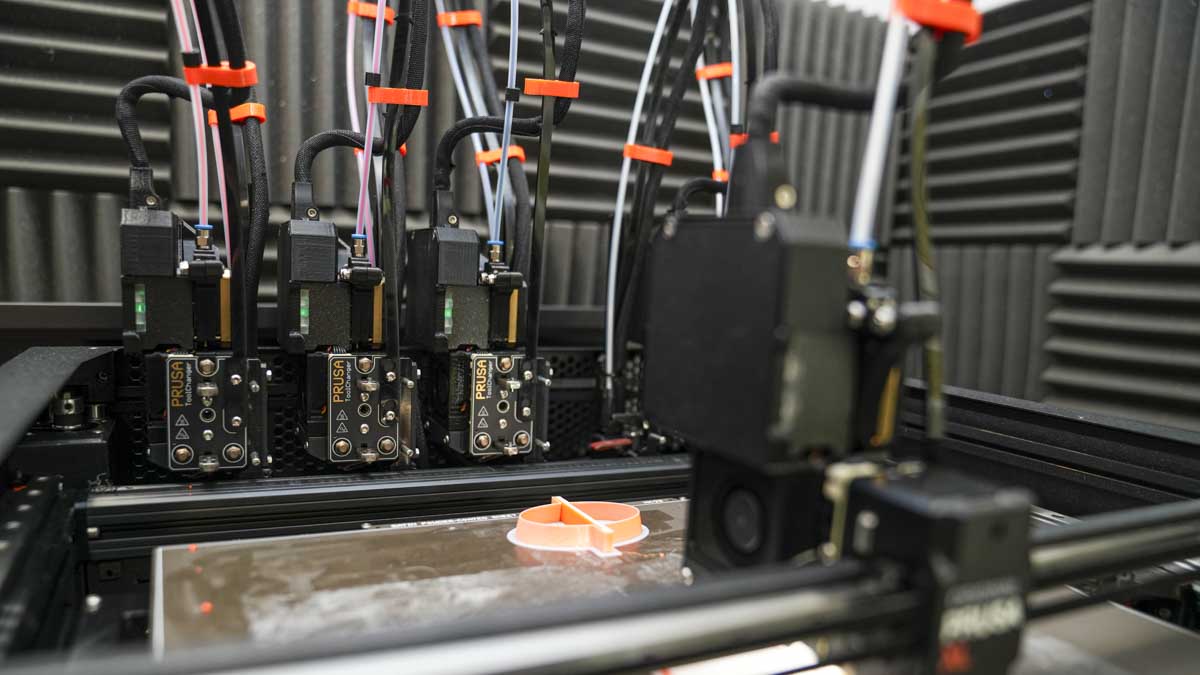

The Original Prusa XL takes 3D printing to another level both in features and scale. This is one of the largest 3D printers that I have looked at and utilises the latest COREXY mechanics that have been coupled with Prusa's latest innovations.

This machine has been designed as a modular and can adapt and change as you and your business need, from a single filament machine to a multifilament with four tool heads. However, where it differs from everything else is that it features a multi-tool changer head, which cuts out the need for filaments to be loaded and unloaded during printing. Instead, the head quickly swaps automatically, dramatically cutting down print times when multifilament printing.

In use, the XL impressed me from the outset with the speed of the changes, enabling the printing of prototype interaction in multiple different materials quickly. This machine is rarely out of action in the workshop and compliments the smaller MK4S which is utilised for speed and single filament prints. In use, the design feels far more akin to professional workshop machinery than a desktop printer, making it an ideal option for all precision engineering.

Read our full Original Prusa XL review

Best 3D printer for miniatures

Specifications

Reasons to buy

Reasons to avoid

✅ You want a 3D printer for miniatures and making models

✅ You have limited desk space

❌ You don't like the mess of resin printers

❌ You don't need the fine detail offered by resin printers

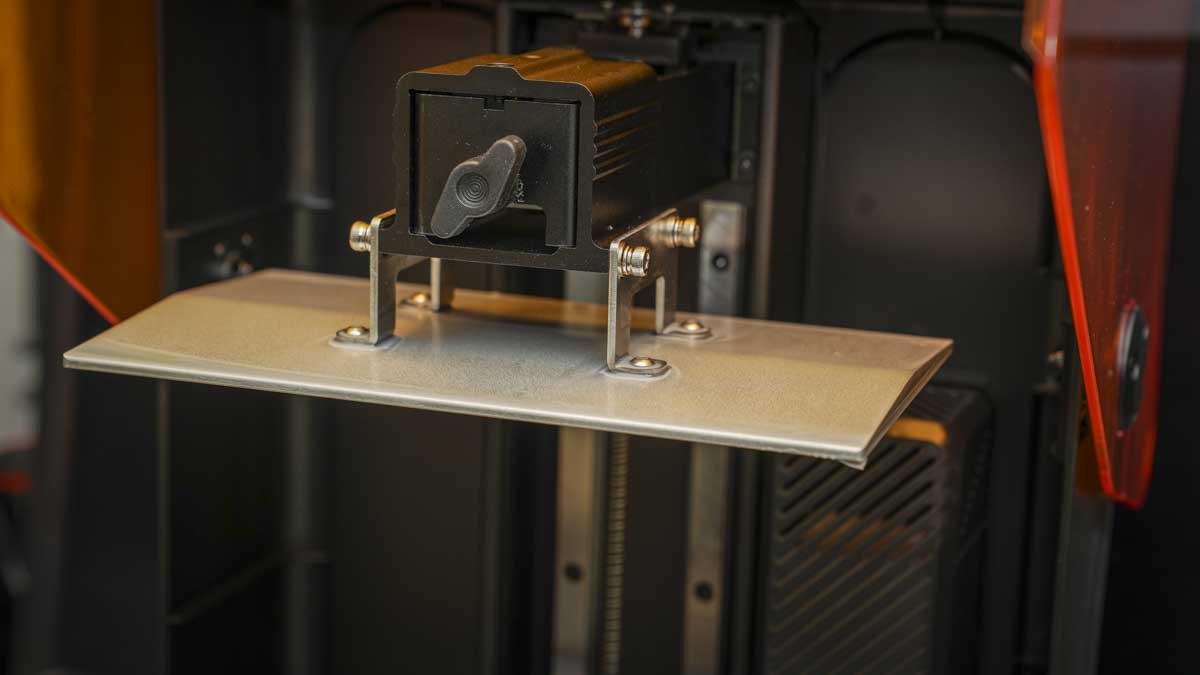

Through the test of the Creality Harlot-Mage S 14K, as with the 8K version before it, impressed. Setup and use were easy enough despite the usual mess that comes with using a resin print. Although with the flip lid design and quick-release build platform and resin tank, it goes some way to making life a little easier. While I found the basics of using the machine straightforward, there is, as ever, the usual clean-up process that requires both wash and cure. While Creality has paired back this machine, so there's no auto-fill feature, the refinements to the resin tank have made the overall use that much easier.

This machine really excels in terms of the quality of the prints, and at 14K, it's one of the highest-resolution printers out there. Sure enough, as the prints emerged, it was possible to see the detail, and after washing, breaking away the support structures and then curing, I saw some of the highest quality prints from this level of 3D printer.

Along with the print quality, I liked the platform size, which is about mid-range sized for this type of printer and essentially makes the quantity of resin in the tank manageable when it comes to the clean-up. I found the quality of the prints from this relatively inexpensive resin printer exceptional, which makes it my choice as the best 3D printer for miniatures.

Read our full Creality Harlot-Mage S 14K review

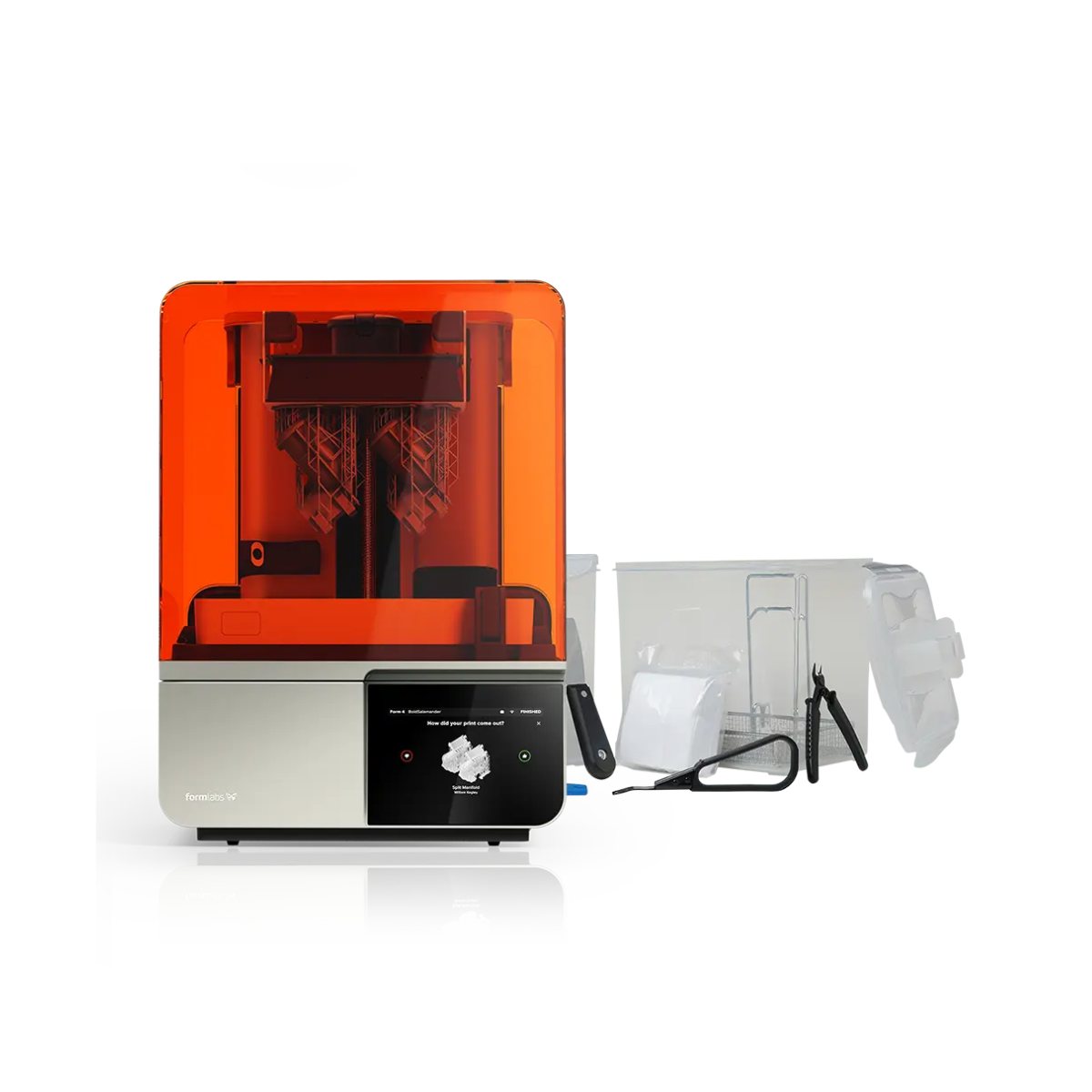

Best 3D printer for small parts production

Specifications

Reasons to buy

Reasons to avoid

✅ You are a professional and looking for the best quality possible

✅ You need a machine for small part production

❌ You are limited on budget, there's nothing cheap about this machine

❌ You don't have a good amount of space. Alongside the Form 4 you'll need the wash and cure

If there's one printer that closes the gap between mass-scale injection moulding and 3D printing, then that's the FormLabs Form 4. Throughout my testing, I was amazed at the quality of the prints that the machine was capable of producing at such a great speed. This makes it a very viable option for anyone looking at 3D printing as a solution for small production runs.

Over the previous generation, which was equally as impressive when it came to print quality, the Form 4 adds a new and improved auto-fill feature and redesigned resin tanks, which both help to take the ease of use up a level.

The main drawback of the machine is the initial cost, and while this will be prohibitive for many users, this is a machine that is solely aimed at the professional market. However, one aspect that I really liked is that while the FormLabs materials are expensive, the system has now been opened up so cheaper materials can be used.

Read our full FormLabs Form 4 review

Best 3D printers: Also tested

The 3D printing landscape is constantly changing, and I've reviewed many more. Some of my favorite top-rated 3D printers include...

Possibly the peak of this generation of 3D printers, the Bambu Lab P2S is exceptional at what it does, and I found performance and print quality superb. However, it's not yet available in the US.

Read our full Bambu Lab P2S review

Pros

- Refined design

- Easy to use

- Specialist material compatibility

Cons

- No active heated chamber

- Creates a lot of waste

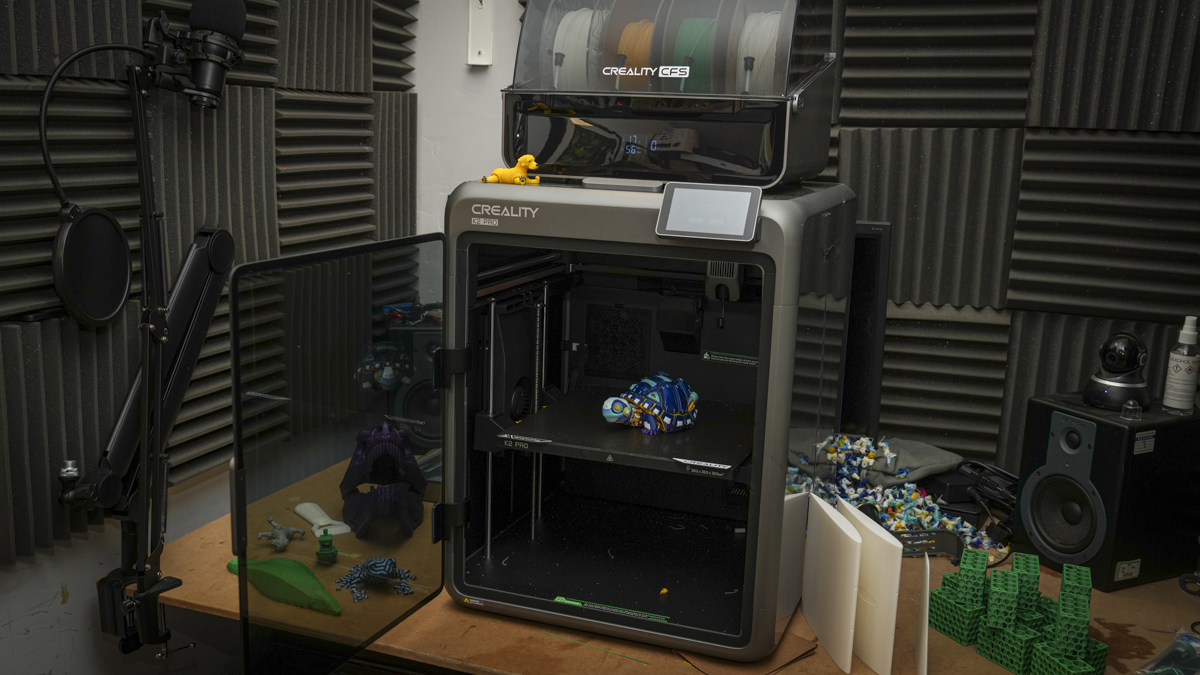

The Creality K2 Pro is the most reliable 3D printer I've ever used. Yes, it has its quirks, but when testing this unit I discovered it really delivered on its build quality, speed and potential.

Read our full Creality K2 Pro review

Pros

- Excellent speed

- High-quality build

- Easy to use

Cons

- Produces plenty of waste

- Slow multicolour printing

This 3D printer is, in my experience, ideal for most people and general use-cases. It's small, fun to use, and easy, too, while producing good quality 3D prints.

Read our full Bambu Lab A1 review

Pros

- Ultra-fast printing

- Multi-filament versatility

- Exceptional build quality

Cons

- Complex software

- No enclosure

- 80ºC heated platform limit

The Creality Ender-3 V3 SE is a great choice if you're looking for an affordable 3D printer that's simple to get started and easy to use.

Read our full Creality Ender-3 V3 SE review

Pros

- Affordable accessibility

- Reliable performance

- User-friendly features

Cons

- No touchscreen

- No filament run-out sensor

- No camera

The Creality K1C is tailor-made for use in education - not least thanks to its sturdy build construction. It's a fast 3D printer that even boasts an AI camera.

Read our full Creality K1C review

Pros

- High-quality build

- Fast print speeds

- Refined AI camera

Cons

- Print quality affected by speed

Fast and accurate, the Anycubic Kobra S1 is the first 3D printer I've tested to score 30 / 30 in the print quality test. If you're looking for accuracy and fine-detail, you'll find it here.

Read our full Anycubic Kobra S1 review

Pros

- Outstanding value

- High precision

- Quality multicolour printing

Cons

- Two power supplies are required

- Limited to eight filaments

Best 3D printers: FAQs

What is a 3D printer?

Where office-style printers print ink onto paper, you can use 3D printers to build real-world objects made from plastic, metal, and wood digital models for straight-to-market products, spare parts, or prototyping. FDM printers now come in all shapes and sizes and are well-suited to prototyping and crafting larger objects. At the same time, resin-based (SLA, MSLA, and DLP) printers allow for much greater detail, typically at a smaller scale, making them a fantastic buy for anyone looking to design jewelry or create tabletop miniatures.

Whether you are a hobbyist looking to get started in the world of 3D printing or if your business relies on it, 3D printing is a method of creating physical products, unlike any other way we have seen. Printing in 3D is an easy way to create products through additive measures, meaning there is little to no waste. Additionally, the limits are near endless because you can theoretically 3D print just about anything.

What kind of materials does a 3D printer use to print?

3D printers utilize a range of materials to print.

Entry-level FFF 3D printers remain the most popular, as they're usually cheap and easy to use. Good for prototyping and general use, these filament printers use Poly Lactic Acid (PLA), Acrylonitrile Butadiene Styrene (ABS), PETG, TPU, Nylon, and Polycarbonate. Of these, PLA and ABS are the most popular at the moment.

A resin 3D printer or stereolithography (SLA) printer offers higher quality and more precision for intricate modeling - but they cost more. These printers use a photosensitive resin exposed layer by layer to create the final model. This lets you print more complex and detailed designs, but takes more time to set up and it’s a bit messier.

Beyond plastics, some of the best 3D printers we've seen are using concretes and metals. You won't see many of these on a desktop. But it's a possible path towards more efficient and sustainable house-building and other large-scale construction work.

What's the difference between FFF vs FDM 3D printers?

While effectively employing the same printing process and using the same materials, there are some differences between a fused filament fabrication (FFF), fused deposition modeling (FDM) printer.

Firstly, FDM is a name trademarked by Stratasys - although other companies can use the name. But it's not the only difference.

You'll find variations in print quality. Working with more materials than FFF 3D printers, true industrial-grade FDM printers offer larger build platforms, fusing use layers closer together for a stronger bond.

On the other hand, this makes them more expensive to buy and run compared to FFF printers, which are popular especially among beginners.

Do 3D printers use a lot of electricity?

It depends on the size of your 3D printer, what materials are being used and how long you're using the machine. In our experience, FDM printers use the least amount of power compared to other 3D printers.

What is the most profitable thing to make with a 3D printer?

There are a wide range of profitable items that can be made with a 3D printer. These range from personalized items such as phone cases an others, to replacements parts, prototypes, and teaching tools. Any of those areas, if marketed correctly, has the potential to be profitable.

Is 3D printing worth investing in?

It depends on how you intend to use your 3D printer and how often (like most things, really). If you're going to get joy out of modeling and printing - whether it's for personal or professional use, then 3D printing is absolutely worth the investment - especially since costs for entry-level 3D printers are coming down.

How to choose the best 3D printer for you

To select the best 3D printer, you'll need to consider what you're going to do with it. If you're going to be printing small objects, then a small-size printer is apt, but a large printer is naturally the best option for bigger creations.

For printing high-quality objects with fine details, you'll need a high resolution printer, but these prints will cost more and take more time to get ready. For additional savings, watch out for Prime Day 3D printer deals and Black Friday 3D printer deals for once the sales are live.

Look out for the printer's interface and the overall ease of use, along with other aspects like the kind of software it uses, the type of filament, build platform, and pricing.

Find our more in our guide How to get started in 3D printing.

How we test the best 3D printers

TechRadar Pro has tested, reviewed, and rated a whole range of printing tools, tech, and services, from the best home printers to the best 3D printers for miniatures. And the team applies the same rigorous testing process to every model so you can make an informed choice.

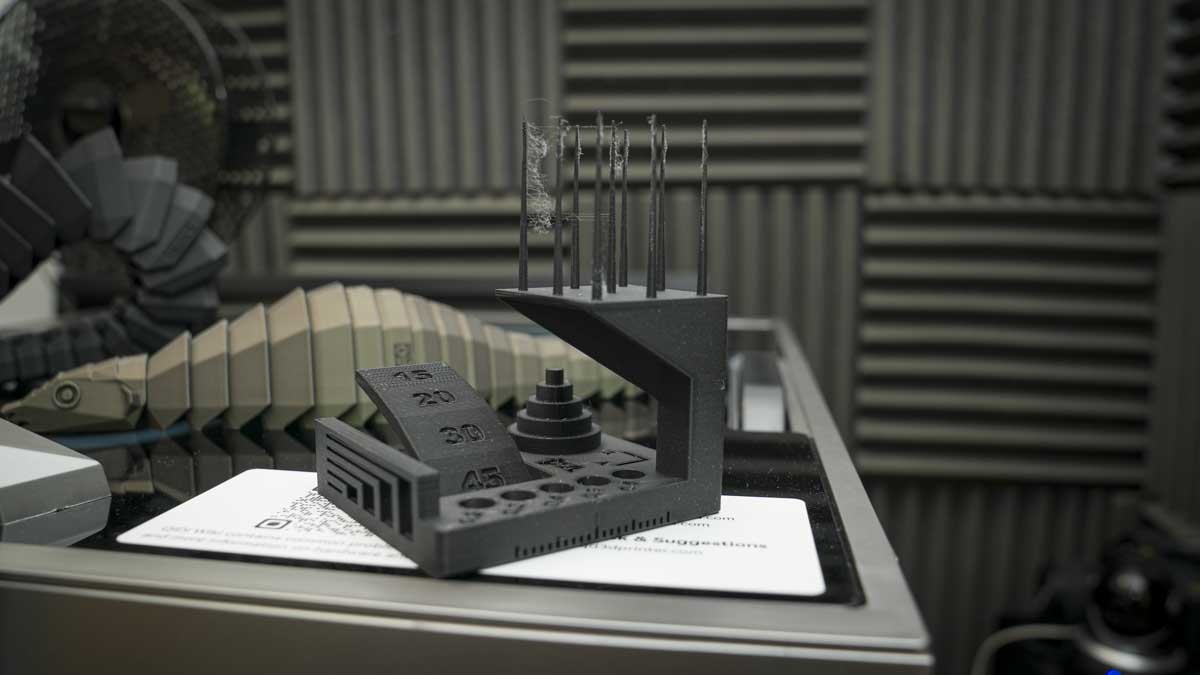

My testing of the best 3D printers use a collection of bespoke benchmarks that help show the strengths and weaknesses of each model that, after time, can be compared against other products. These will differ depending on printer type, but a filament printer will be tested for stringing, bridging, and speed, as well as additional commentary on detail, achieved, and noise levels.

This will be done fairly, with dues given to different materials and printer types, with resin printers being subject to smaller, more detailed models to replace the stringing test. Design, price, and performance will also be explored as sections within the reviews.

In my 3D print workshop, every 3D printer undergoes a comprehensive testing process, regardless of whether it's budget-friendly or eye-wateringly expensive. Our testing procedures are designed to put these printers through rigorous evaluations to ensure we identify the best options available for you.

The testing journey begins with the initial build, set-up and calibration, assessing the ease of the process. While some printers can be up and running within minutes, others may require far more time and effort.

Next, I examine the first layer print quality, dimensional accuracy, bridging, overhangs, stringing, layer adhesion, and surface finish. Speed is another important factor, as I analyse the time it takes the printer to produce a model without compromising print quality. Noise levels are also a consideration; some printers are far from quiet, especially when the speed picks up - OK for short prints but incredibly annoying if a print duration is hours or days long.

My comprehensive testing includes thoroughly examining features, such as connectivity options, user interface intuitiveness, software compatibility, and any additional functionalities offered. I also explore material compatibility, testing the printer with various filaments or resins to assess versatility.

Finally, I consider the price against the printer's overall performance and features, ensuring it aligns with our expectations. I carefully evaluate the intended market for the printer, considering specific user needs and suitability for various applications. Additionally, I analyse the design and aesthetics, recognising the importance of a well-designed and visually appealing product.

By subjecting each printer to these tests and assessments, I can confidently provide you with an informed recommendation as to which is the best 3D printer for your specific needs.

All of my tests are conducted from the perspective of the printers target market where possible, so expect to see a lot of tabletop miniatures and figurines alongside the usual 'benches' (test models that are also dubbed as 'torture tests' to see where a printer needs to be better optimized for future prints).

For more crafting tools, we've tested and reviewed the best laser engravers.

Sign up to the TechRadar Pro newsletter to get all the top news, opinion, features and guidance your business needs to succeed!

Alastair is a photographer, filmmaker and tech writer who has been working in the publishing industry since the late 1990s. For more than 25 years he has covered photography, video and technology across Future's photography, technology and gaming brands. He runs a photography and video production company and lectures in TV and film. He can usually be found testing mini PCs or prototyping and prop building with the aid of 3D printing.

- Steve ClarkB2B Editor - Creative & Hardware