TechRadar Verdict

If this machine had hit the shelves just a few months ago, it would have gone straight to the top of our best 3D printers list. It's absolutely superb. However, in the wings are the new multitool printers, and while this printer is exceptionally refined, it feels like the last of its generation.

Pros

- +

Refined design

- +

Easy to use

- +

Specialist material compatibility

Cons

- -

No active heated chamber

- -

Creates a lot of waste

Why you can trust TechRadar

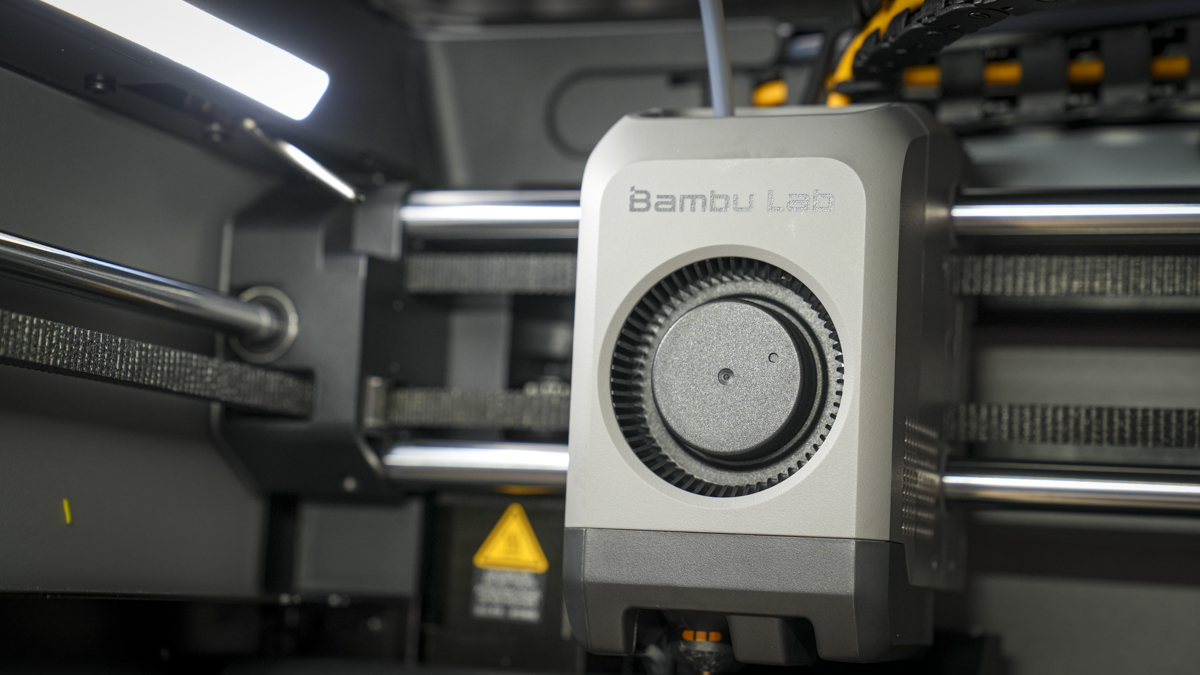

The Bambu P2S is the hotly anticipated successor to the best-selling Bambu Lab P1S, and in every way, it's a significant upgrade. With the experience Bambu Lab has gained since the release of the P1S, it's no wonder the P2S is so incredibly refined. I've been running this machine constantly for over three weeks with very little in the way of failures or misprints. It's just streamlined, easy to use, and very obvious that many of the features have trickled down from the X1 Carbon and H2D.

Why that's significant is that now you have this premium entry-to mid-range machine that essentially offers much the same as the X1 Carbon did when that was launched at the pro level just a few years ago. The AMS 2 Pro works exceptionally well and is exactly the same version as you find on the top-end machines, with the same ability to expand to multiple filament printing straight out of the box. Having battled with many multifilament boxes over the last month, I can absolutely confirm that the AMS 2 Pro is one of the best out there. It's just simple to use and extremely reliable, especially with ceramic feeders.

Bambu Lab have introduced a huge number of additional features compared to the P1S. For instance, with the advancement of the latest technology, there's now AI monitoring, automatic flow calibration, and adaptive airflow that helps to manage both standard PLA filaments and many more advanced options, including carbon-filled ones. Although it's worth noting that while it can handle many specialist materials, it doesn't quite take that leap up to an active heated chamber like the H2 series.

Connectivity is also well catered for, with a very reliable Wi-Fi connection that enables you to send prints directly from your Mac, PC, or even Android or iOS device. However, if you're thinking about this for a professional environment, one slight disappointment, particularly for those in education or engineering, is the lack of an Ethernet port. Still, it's good to see that a USB socket for direct file transfer has been retained.

As a step up from the P1S, it's a natural progression. If you think of the P2S as a more refined version of the P1S with the latest technology, then that's exactly what you're getting. My only consideration is that, while the print quality of this machine is exceptional, since the launch of the Snapmaker U1, the 3D print landscape has changed. So, while this is an exceptionally good machine that offers huge reliability and compatibility, you can't help feeling that this might be the last of a generation, as this technology and format reach their pinnacle of refinement.

Bambu Lab P2S: Price and availability

The P2S is available now globally from the Bambu Lab website, aside from the US, where the product will be listed but at present will not be available for purchase. The availability and price are still to be confirmed; the US prices below are an estimate, but could be higher.

P2S

Sign up to the TechRadar Pro newsletter to get all the top news, opinion, features and guidance your business needs to succeed!

US (excl. tax): $549 | EU (incl. tax): €519 | CA (excl. tax): $799 CAD

UK (incl. tax): £479 | AU (incl. tax): $949 AUD | Global (excl. tax): $519 USD

P2S Combo

US (excl. tax): $799 | EU (incl. tax): €749 | CA (excl. tax): $1,049 CAD

UK (incl. tax): £699 | AU (incl. tax): $1,249 AUD | Global (excl. tax): $749 USD

Bambu Lab P2S: Design

Compared with your previous P1 series machines, you can really see just how far Bambu Lab has come in just a couple of years. The design and build quality are a level up, and had this been released just a year ago, it would've been right up at the premium end of the market. This just sets the tone for a machine that is now aimed at the beginner to mid-level 3D print enthusiast.

When it comes to the size and weight of the machine, it comes in at 14.7 kg and measures 392 × 406 × 478 mm. This makes it far more convenient and easier to move around than the larger machines, and for anyone in a standard-sized workshop or office, it will be an ideal option.

From the moment the machine is removed from the packaging, you can tell that the design and quality of the manufacture and build is a huge level up from the P1S, with steel, plastic, and glass all coming together in a very refined design and aesthetic.

Looking over the machine, it's very obvious that Bambu Lab have learned a huge amount about the design of their 3D printers and pulled feedback from their users about the functions and features they want. While some manufacturers have eliminated core features such as a simple USB direct connection, it's great to see that Bambu has retained this simple feature. So a USB stick can still be used.

Once again, as with the P1S rather than the P1P, it's a fully enclosed design, which enables you to print with more specialist materials, including ABS and, to a certain extent, PETG.

One of the big aesthetic changes from the P1S is the inclusion of a 5-inch touchscreen featuring the second generation of Bambu Lab's user interface, which is extremely fast and responsive. It gives you a clear view of print progress and settings, making it extremely easy to navigate, even for those completely new to 3D printing.

While this printer is aimed at the beginner to mid-range market, it does carry a slight price premium and offers high-quality features that are better than what you find on cheaper entry-level machines. These include a decent resolution camera that offers live remote monitoring and the ability to capture time-lapse video.

There are also some interesting mechanical changes. On the P1P and P1S, carbon rods were used. While they worked exceptionally well, they weren't easy to maintain. From both a cost and maintenance perspective, those rods have now been replaced with smooth metal rods that are far easier to look after.

Anyone who uses 3D printers regularly will know that, while hot ends last relatively well, there will inevitably be a time when they need to be swapped out. If you had a 3D printer in the early days, you probably remember that the process could be both costly and time-consuming; now it takes less than a minute, and the hotends, even specialist ones, are relatively cheap.

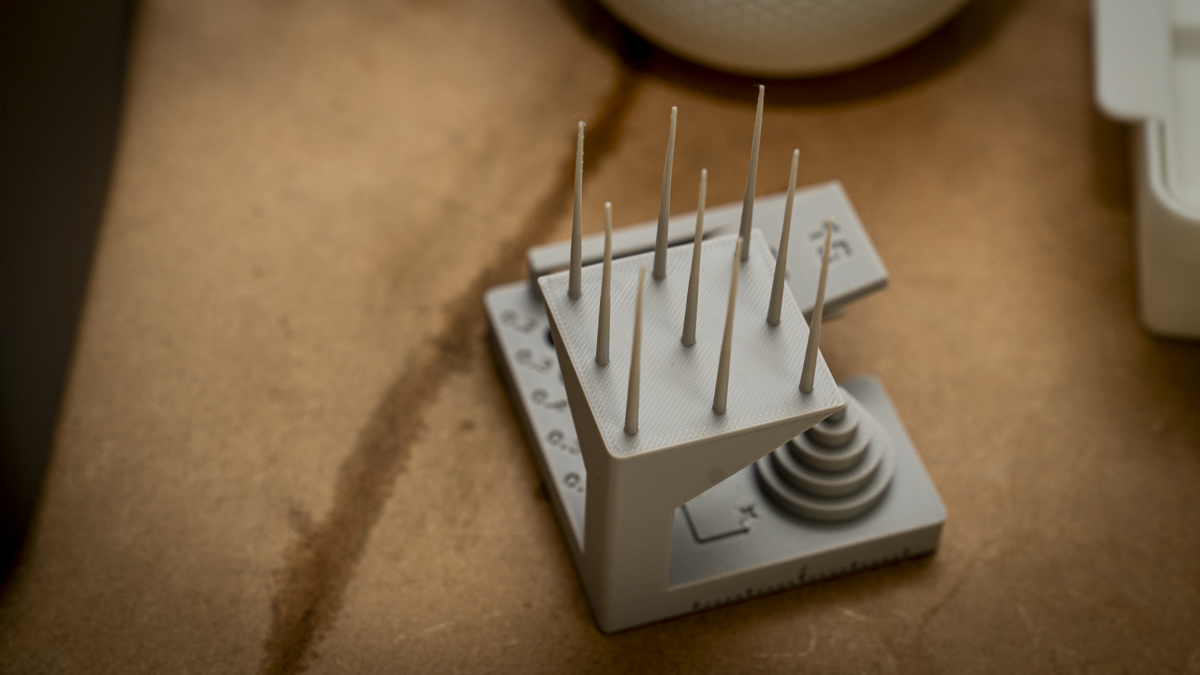

Along with the printer, Bambu Lab also sent me a selection of hot ends, including the 0.4mm (installed by default), a very fine 0.2mm for intricate printing (perfect for FFF-ready miniatures), and 0.6mm and 0.8mm nozzles for faster printing. What I really liked here was the new design of the head, as we've seen with the X1C and other recent printers; those nozzles can be swapped out quickly. More than that, the system automatically updates along with the software, so you always have the correct settings for your print.

Bambu Lab made their name in multifilament 3D printers, not only able to make the process easy but also to print at high quality. Part of that has always been due to the built-in filament cutter and odometry system, which again shows the evolution of their machines. I have to say it's just as effective here as in the H2 series.

Overall, the design has evolved and improved, and for anyone wanting to upgrade to the latest in everything these machines offer, the P2S is about as refined as they come.

Bambu Lab P2S: Features

After checking over the design of the P2S, you can see that it's a very different machine from the P1S, with a full upgrade across the board. The first thing that really strikes you is the new large touchscreen, which features a fast processor that keeps up with navigation through the neatly designed user interface. It's quick, and even when you pop in a USB stick with large and complex models, files load quickly. Likewise, when using it over the network, the internal processor has enough power to handle files and commands at speed.

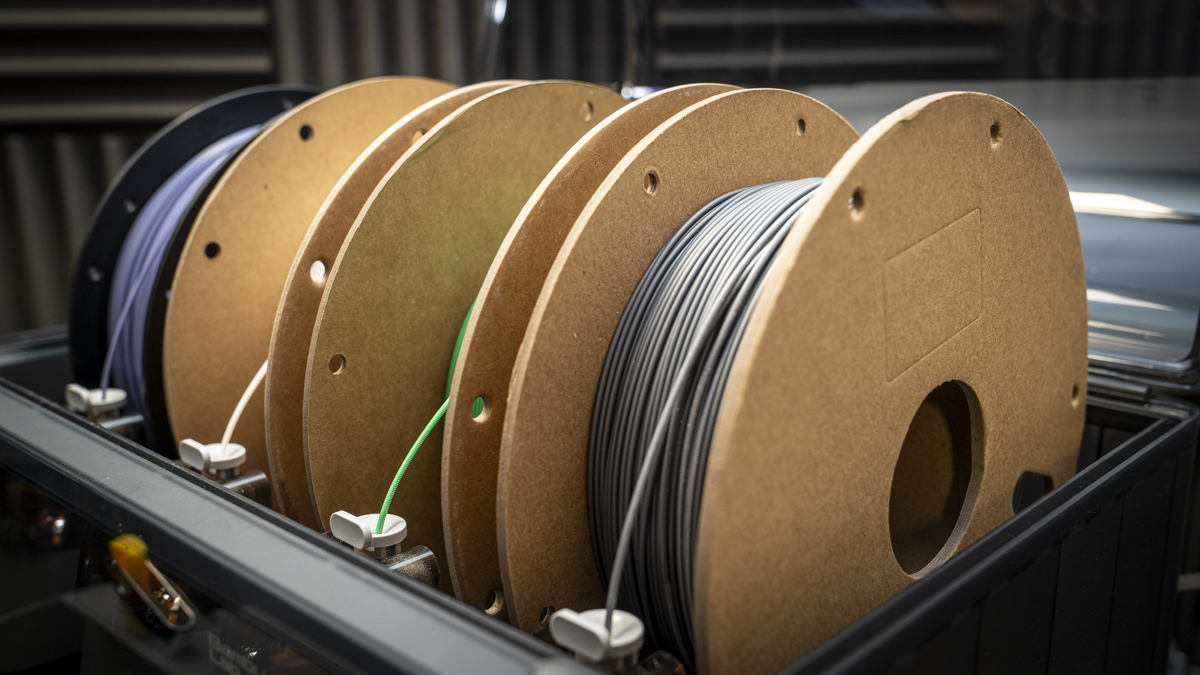

As seen previously, there's the AMS 2 Pro that ships with the machine. This is the same as we've seen on the H2 machines at the premium end of the range and offers filament drying and an active venting system to keep filaments in top condition. It also features an RFID reader, so if you pop in Bambu Lab filament, the filament colour, type, and weight are instantly recognised.

One of the great features of the AMS units is that you can link several together. With the P2S, you're able to connect up to four AMS 2 Pro units and four AMS Lite units, totalling eight AMS units in total, and up to 20 slots, enabling, for the first time, 20-filament 3D printing in this premium entry-to mid-level machine.

The new PMSM servo extruder is one of the big new features, as it enables up to 8.5 kg of force, essentially enabling the use of high-flow filaments. One thing I noticed during use is just how good it is at detecting issues, with real-time detection of clogs and grinding from the extruder. If any issue arises, such as a slightly bent cardboard reel jamming the system, proceedings will come to an abrupt halt so you can fix it before any damage or misprint occurs.

The P2S also utilises a high-resolution, high-frequency eddy current sensor that measures nozzle pressure and actively adjusts the flow rate based on readings, ensuring consistent extrusion across a multitude of filament types throughout the print.

AI error detection is a big feature of many 3D printers now, and here again, computer vision detects common issues such as spaghetti or nozzle clogs. As soon as anything is detected, the print stops so the issue can be resolved.

Complementing this is adaptive airflow cooling. This is passive, with the system drawing air from outside the chamber to keep temperatures down, even when printing low-temperature filament such as PLA, which usually requires open-door systems.

On the flipside, there's also adaptive airflow heat preserving. A flap-control active airflow system helps seal heat within the build chamber. If you're using specialist materials, any fumes are still filtered through the carbon filter. So, if you're using this in an enclosed space, a good amount of fumes will be removed, though it's always best to use these printers in a well-ventilated environment.

While many 3D printers now use cameras, even at entry level, it's great to see that there's a 1080p high-rate live-view option. You can monitor print progress through the Bambu Lab slicer software, and also capture time-lapse footage ready for social media.

When it comes to connecting to the printer, there are two options: either through Wi-Fi using Bambu Studio or by transferring the file directly using USB.

Finally, one of the big features for me was the support for many specialist materials, and also the option to quickly interchange nozzles. The machine ships with the universal 0.4mm nozzle, and you can easily switch to 0.2mm, 0.6mm, or 0.8mm sizes depending on your needs. What's really nice here is how quick the process is; it takes just a few minutes, if that.

Bambu Lab P2S: Performance

One of the things I love about Bambu printers is that once you have everything out of the box, it only takes 5–10 minutes to set up and get the machine running through its calibration process. The mechanics of setup are easy, and once it's powered on and the AMS 2 Pro is connected, the machine handles everything else. All you need to do is sit back and unpack four rolls of filament to pop into the machine once calibration is complete.

The calibration process took around 30 minutes. Once I returned, I popped in four reels of filament and let them automatically feed through the system. They were all recognised instantly by the RFID chips; no need to manually enter any filament types, and everything was sorted automatically.

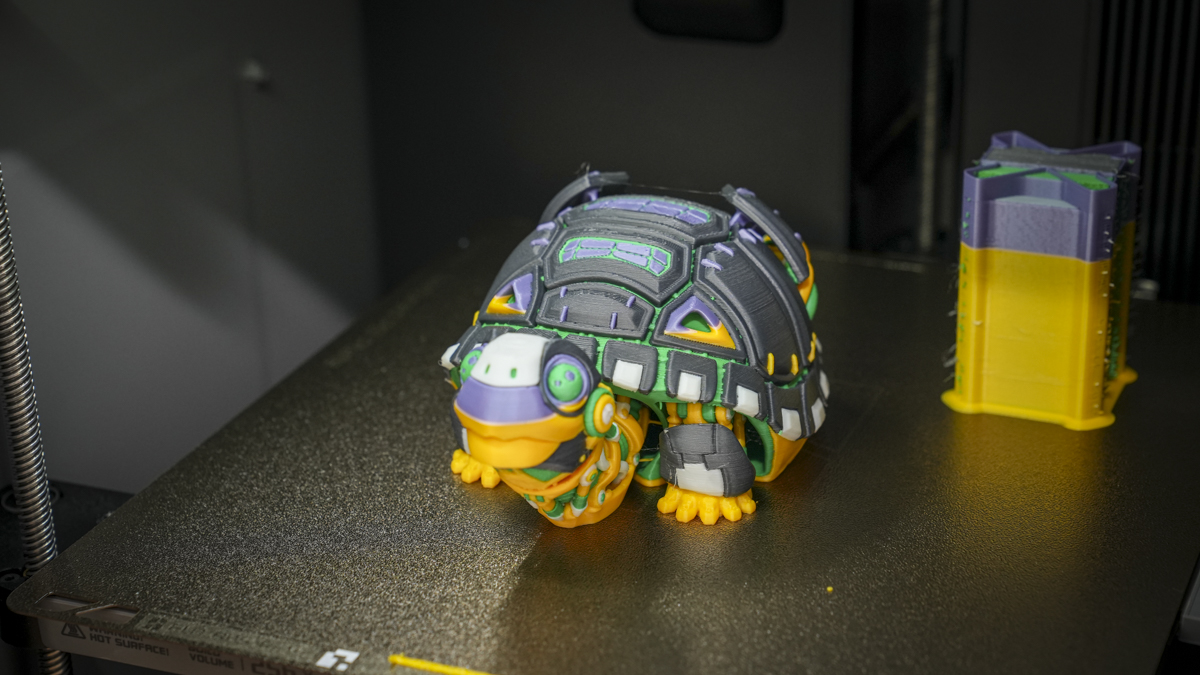

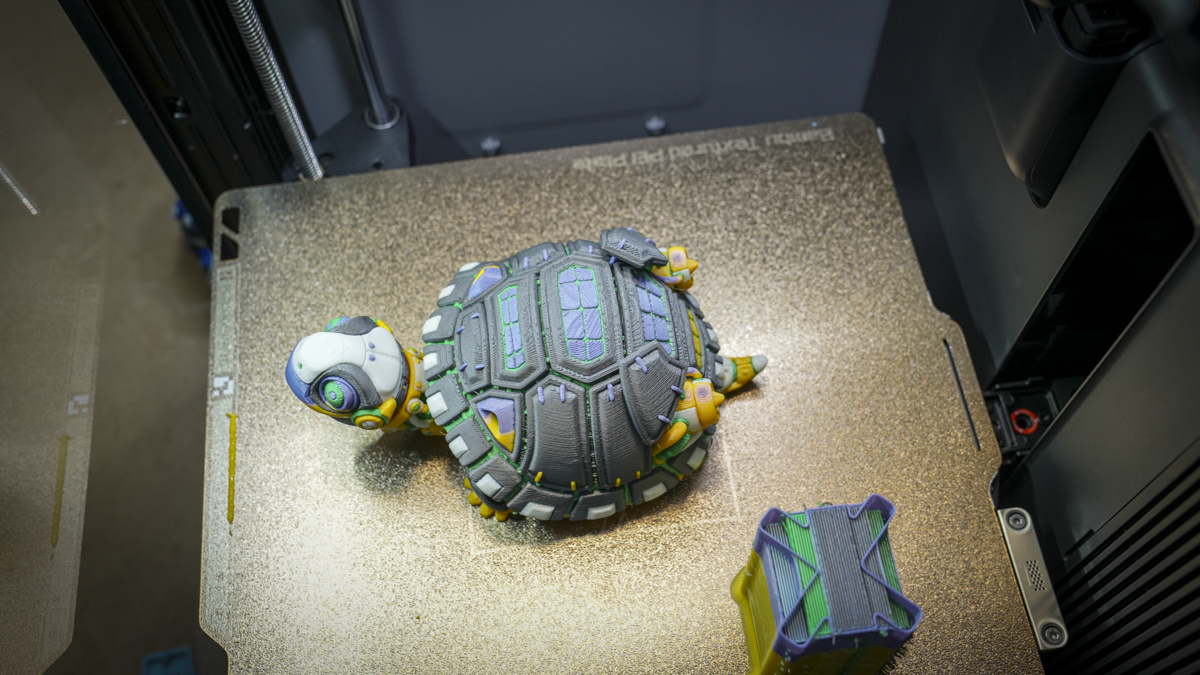

I then spent the next couple of days running through all of the test models, simply returning to the machine to remove each print, start the next, and occasionally change filament for colour. Throughout this process, there was no additional adjustment, no extra calibration, and absolutely no failed prints. The process was as easy as you always imagined 3D printing should be.

However, I've had countless experiences where pre-optimised prints loaded onto the system work perfectly, only to find that my own test prints start to fail. But here, after running the machine for over three weeks, print after print completed without issue.

One point to note is that the machine is quite sensitive. Any small issue will cause it to pause until you check it. When I used Bambu Lab plastic reels, the machine ran without issue, stopping only if a filament had run out. However, when using third-party filaments, or more specifically, those with cardboard reels, the printer stopped far more frequently. Still, the extruder packs in some serious force, compensating for most issues. Even when the printer paused, it always resumed and completed prints without problems.

If this were my first printer, the build quality, user interface, speed, multifilament capabilities, and ultimate print quality would absolutely impress. While I do like the X1C and the Creality K2 Pro, when it comes to print quality, there's no difference in the result compared to this much cheaper machine.

I have to say that, while having larger machines such as the Bambu Lab H2S and Creality K2 Plus is often useful, especially for printing big brackets or stands, having a small, neat, fully enclosed machine like this is far more convenient. Most of what I print day-to-day is single filament.

I have a Prusa Core One on my desk, and in the workshop, I have the Bambu Lab H2D ready for multifilament printing. This small machine offers me both multifilament support and the convenience of size.

Essentially, if you look at CoreXY machines that took over from Cartesian about 2–3 years ago, this is now the pinnacle of refinement for that style of single-toolhead machine. Had this machine been launched just three months ago, it would've instantly rocketed to the best 3D printer position.

Everything about it is so refined, and its reliability and quality are exactly what you'd expect. It's a no-fuss option, and for any classroom, business, or workshop, it's a solid choice in terms of build quality and ease of use.

Bambu Lab P2S: Print quality

Target 25 = X: 24.85mm / 0.15mm Error | Y: 24.93mm / 0.07mm Error

Target 20 = X: 19.79mm / 0.21mm Error | Y: 19.92mm / 0.08mm Error

Target 15 = X: 14.71mm / 0.29mm Error | Y: 14.89mm / 0.11mm Error

Target 10 = X: 9.75mm / 0.25mm Error | Y: 9.89mm / 0.11mm Error

Target 5 = X: 4.85mm / 0.15mm Error | Y: 4.92mm / 0.08mm Error

X Error Average = 0.21

Y Error Average = 0.09

X&Y Error Average = 0.15

Fine Flow Control – score: 5

Fine Negative Features – score: 5

Overhangs – score: 4

Bridging – score: 5

XY resonance – score: 2.5

Z-axis alignment – score: 2.5

Total: 28 / 30

Bambu Lab P2S: Final verdict

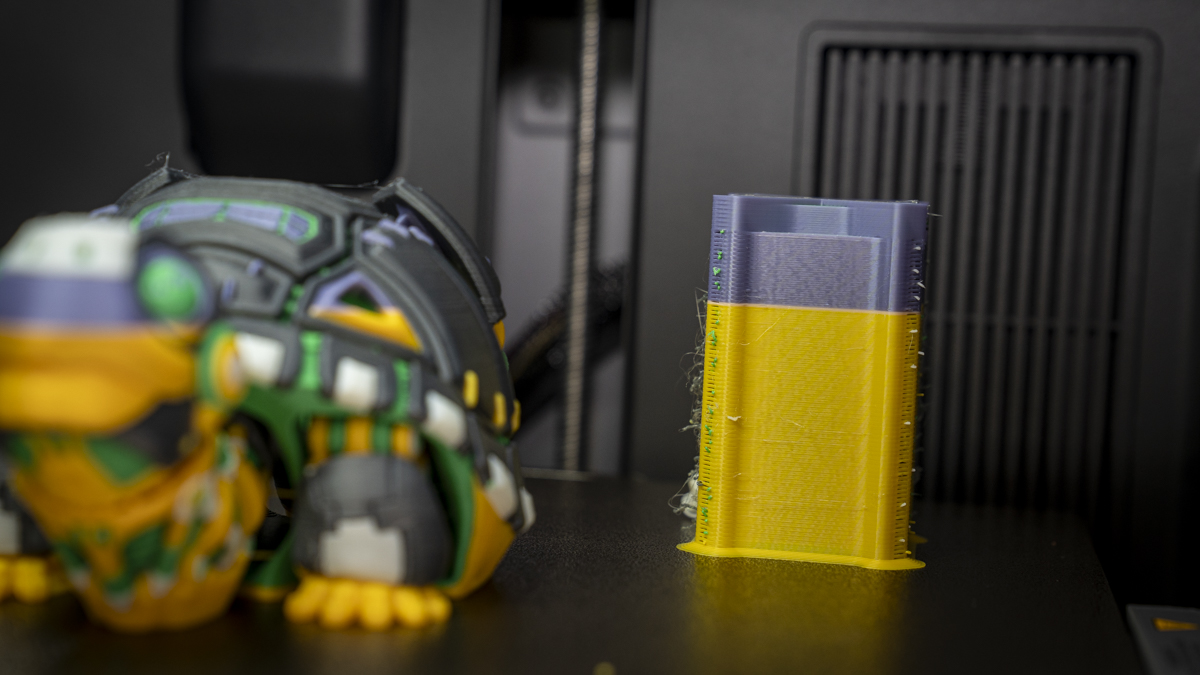

I like this machine, it's feature-packed and a great size; however, as with all of these single-head machines, and even with the H2D with its dual-nozzle system, the volume of waste produced is still huge. As I ran various multicoloured prints through the test, the piles of waste at the back started to mount up. While the quality of the prints was exceptionally good, there's also that time penalty: each filament change requires the old filament to be purged and the new one loaded.

This is something I've become used to. To be honest, if I have complex multicolour prints, I now run them on the Original Prusa XL every time. That machine costs far less in filament for larger prints due to the pure lack of waste it produces. But then again, it's a significantly more expensive machine, at least until the arrival of the Snapmaker U1.

Let's also not forget about Bambu Lab's recent announcement of the H2C. The Vortek system certainly looks to take things to the next level, and I'm personally intrigued to see how the AMS is going to be integrated, as is my colleague Mark Pickavance, who has some superb ideas on the matter.

Considering the cost of that machine at present, the lack of waste and speed for complex models really does make it appealing, and possibly, even with how refined the P2S is, difficult to argue the case for it over the waste and filament cost factors offered by the U1.

That was my big question throughout this review: I was looking at one of the best CoreXY, fully enclosed, single-head 3D printers ever made, and yet I'm still doubting it because of the Snapmaker U1. While the U1 can't match the P2S on overall print quality, there's enough in that new machine to make it more appealing than even the very best single-head option I'm looking at now.

I had to really think about why someone would go for the P2S over the Snapmaker U1. As I thought about it, the reasons started to become a little more obvious. First and foremost, you have a fully enclosed environment, something the Snapmaker U1 cannot currently provide.

Then you have absolute reliability. It's unusual for a machine to run through several weeks of almost non-stop testing, over 300 hours of print time, without some kind of failure. Yes, the machine paused occasionally for a model or filament change, but not one blockage, not one model came loose from the base. It just worked.

While the Snapmaker U1 is a phenomenal machine, it is not quite at this level when it comes to absolute print quality and reliability. The finish of the models on the P2S is simply exceptional, but as the performance test showed, there is room for improvement in the dimensional accuracy.

Then there's the ease of use and maintenance, which Bambu Lab has clearly focused on, like swapping carbon rods for steel ones. And when it comes to a machine that sits neatly in a corner without being oversized, the P2S ticks all the right boxes.

I do feel there's a 3D print evolution happening right now, and in the coming months, we're going to see a whole host of new printers. For now, though, this feels like a machine that marks the end of an era in 3D printing, and shows the absolute peak of what's achievable in this generation, just as the original Prusa Mk4S marked the end of the premium open-frame era.

Should I buy the Bambu Lab P2S?

Buy it if...

You want flagship features without paying flagship prices

The P2S borrows core technology from Bambu's premium machines, offering performance and reliability at a much more accessible price.

You print in multiple colours or materials.

With support for up to 20 spools via AMS 2 Pro, the P2S Combo is perfect for multicolour and multimaterial workflows, with integrated filament drying to boot.

Don't buy it if...

You need active chamber heating for high-temp polymers

The P2S lacks an active heating system for the print chamber, making it less suitable for advanced filaments like ASA and ABS

You want an open-source or mod-heavy machine.

This printer lives in Bambu's closed ecosystem. If you want to tinker with firmware or hardware mods, you'll hit obvious limitations.

For more models, I've tested the best 3D printers you can get right now.

Alastair is a photographer, filmmaker and tech writer who has been working in the publishing industry since the late 1990s. For more than 25 years he has covered photography, video and technology across Future's photography, technology and gaming brands. He runs a photography and video production company and lectures in TV and film. He can usually be found testing mini PCs or prototyping and prop building with the aid of 3D printing.

You must confirm your public display name before commenting

Please logout and then login again, you will then be prompted to enter your display name.