TechRadar Verdict

The build volume of the H2D was impressive, but with the H2S, we see a leap to 340 x 320 x 340mm. A single nozzle might seem like a step back for industrial and business users, but this machine offers enterprise-level print features and volume at an extremely affordable price.

Pros

- +

Massive build area

- +

Up to 1000 mm/s, 20,000 mm/s² acceleration

- +

PMSM Servo Motor + Vision Encoder precision

Cons

- -

No dual-nozzle

- -

The heated chamber increases running costs

- -

Vision Encoder is optional, not standard

Why you can trust TechRadar

The H2S comes hot on the heels of the H2D full laser combo and standard H2D 3D printer (see my review here), but with a few major differences that make it a superb option for any enterprise business requiring a machine that offers scale, reliability and speed.

It might not have the headline-catching dual nozzle that so interested the 3D printing market, but with much the same form factor, just with a single nozzle rather than dual nozzle tool head, it offers something a little different.

Essentially, Bambu Lab is touting this as a bigger X1C, which has become a staple for many design studios due to its print quality, flexibility, multiple filament printing, and of course, speed. Now, with the H2S taking yet another leap in scale and performance, and what's more, it's also coming in at a relatively affordable price point.

In use, the H2S is impressive, and the single-nozzle hotend is highly tuned for precision and quality. The speed, while quoted as faster than the X1C, in real-world tests using standard settings is on par; however, tweak the options and the full speed of the machine is unleashed, seeing a standard 20-30% boost in print times across the board. The H2S also has a far larger print bed, enabling more potential with the style and type of prints you're able to produce. There's absolutely no doubt that, when it came to side-by-side print quality, the X1C is one of the market leaders, but the H2S just took the edge during my test.

One feature that appeals to me about the H2S is that, compared with the H2D, it is far more affordable and there is a laser option as well, in fact, the new H2S line exactly reflects the H2D, just at a more affordable price.

What this essentially means is that, for any product design studio or anyone looking for the best 3D printer for quality, the Bambu Lab H2S is a balanced option, especially if you mainly print with a single filament with the occasional use of multifilament.

Bambu Lab H2S: Price and availability

There are three versions of the H2S available: the Base, the AMS Combo, and the Laser Full Combo. The two more advanced versions, the AMS Combo and the Laser Full Combo, are available now for $1,499 and $2,099, respectively. Bambu Lab will also be releasing the Base unit, which is just a single-nozzle machine, for $1,249.

Sign up to the TechRadar Pro newsletter to get all the top news, opinion, features and guidance your business needs to succeed!

Each model offers an upgrade route, so if you are working on a budget and just want an exceptionally good single FFM printer, you can start with the Base, then upgrade with the AMS Pro 2 to the AMS Combo. If you want to go all the way, you can upgrade to the Laser Full Combo, but only pick out the additions that you need.

Bambu Lab H2S: Design

Like the H2D, the H2S has almost an identical form factor, so once again it's a large-scale machine that will take up a sizable amount of your desktop, and now that I have three of these machines side by side, that doesn't leave a lot of space for much else.

The fact is, however, that with the H2S, it cuts away a lot of the frills of the H2D and the excitement those machines create. Instead, the H2S goes back to the core of 3D printing, offering a single nozzle toolhead and a few additional features that help elevate what's possible. It positions itself as a successor to the phenomenal X1C, or if not a successor, then a larger-scale version that takes on the new form factor of the H2 series.

At the base level, the first thing you notice alongside that nozzle is the larger print volume, which measures in at 340 × 320 × 340 mm, making it one of the largest on the market. It also once again utilises the CoreXY system, offering high-speed printing, both single and multifilament, when coupled with the AMS Pro 2.

Once again, the 3D printer is fully enclosed, so if you want to print with more advanced materials, that is perfectly possible, with a heated bed that reaches up to 120°C and a 65°C actively heated chamber. This is great for materials like ABS, nylon, and ASA.

One of the features that I've really liked across all of the H2 series is that large touchscreen. It's just really intuitive, beautifully designed, and very quick to respond, which is not always the case.

Inside, they've also boosted the number of sensors, with five flame sensors covering monitoring, emergency stop, and airflow optimisation, once again almost mirroring the H2D series, but building on the feedback and experience of those first H2 machines.

When it comes to the major differences between the H2S and the H2D, aside from that single nozzle toolhead, most of the other differences come in the technology and steps forward in development. For instance, there's second-generation extrusion motion technology with a PMSM servo motor that exerts a 67% increase in extrusion force. There's also a 20 kg feedback load for precise filament control.

Once again, we see the Vision Encoder, which is optional, but will boost the motion accuracy for prints under 50 microns. This is essentially industrial-grade precision, so it will really only be of interest if you're using this for high-precision product design. However, if you're into gaming and want to make desktop game figures, then this is going to be a great feature. I have noted that there are several 3D artists now producing FFF-ready miniatures. With the Vision Encoder having industrial-grade precision, it could mean that printing miniatures on an FFM machine should now, in some cases, be possible, meaning that you don't have to deal with messy resin.

Bambu Lab has also taken a look at monitoring and intelligence, and the H2S includes 23 sensors inside the machine that are monitoring the print process and conditions. This is coupled with three onboard cameras, one for live view, one for the nozzle, and one for monitoring. This compares to just one on the H2D. There's also smarter fault detection if a print does go wrong, and I have to say, during the three-week test, I didn't have any print failures, even when I tried with an impossible print, the machine just detected it and paused.

Now, while the form factor of the machine is identical to the H2D, when it comes to the build volume, because it only has a single nozzle rather than two, the full print bed can be used, so you have a larger print volume of 340 × 320 × 340 mm compared with 325 × 320 × 325 mm for single-filament printing on the H2D.

Bambu Lab also says that the H2S is a high-speed machine, capable of printing up to 1000 mm/s and with acceleration over 20,000 mm/s². However, during my tests, I'd say they are both pretty much on a par until you delve manually into the settings.

Once again, there's a heated chamber, and in the H2S, this is capable of reaching around 65°C, exactly the same as the H2D. Likewise, the hardened steel nozzle seems to be the same, as does the 5-inch touchscreen.

One of the big questions I had when the machine arrived was: because it is a single-nozzle machine, does it still have the capability of using a laser and cutter? There are, of course, three versions of the H2S, including the Laser Full Combo version that offers laser engraving, cutting, digital cutting, and precision drawing capabilities.

Bambu Lab H2S: Features

Take a look through the machine's features, and aside from the single nozzle, which is obvious, the main feature aside from technology enhancement is the larger print area, which means that this is essentially a large successor to the X1C. Through the test, the speed of the H2S impressed. Put alongside the X1C on standard prints, print speeds were essentially similar until you delve into the settings. However, there are more options, and if you really want to push the speed of the printer, it is possible to get up to a 30% faster printout of the H2S than the X1C, although there is a small drop in quality.

The maximum speed of the printhead goes up to 1000 mm/s with 20,000 mm/s² acceleration. So, while the acceleration matches the X1C, the print speed essentially doubles, with a real-world speed increase of around 30%.

Like the H2D, the single nozzle of the H2S is capable of reaching 350°C, which makes it a perfect option for printing engineering-grade materials such as ASA and nylon. The H2S is a fully enclosed environment, which helps ensure optimal printing conditions for those materials, and with the filtration also helps to remove any toxins from the materials as they print.

Once again, Bambu has included a whole series of sensors that will detect if any print goes wrong and stop proceedings before issues are caused. Through the test, aside from running out of filament, I only had one occasion where the error-checking needed to kick in, due to some filament falling onto the print bed from a previous print. The new machine now includes 23 sensors and three onboard cameras. During the test, I didn't have any tricky situations with printing. The one issue that could've caused a problem was instantly recognised, and the printing was paused until I removed the filament, then the print completed successfully.

What I also liked was that when it came to filament changes due to running out, the process of restarting the print was absolutely spot-on. There wasn't the usual worry about layer misalignment that can often happen.

One of the big new features of the extruder is that it now includes a PMSM servo motor that can apply 67% more force. While I couldn't visually see the difference, the extrusion of the filament did seem exceptionally smooth for all materials tried, including Carbon fill and TPU. When I compared prints between the H2D and the H2S, there was very little difference; it was only when testing a specific model that I could see a very slight uplift in the print quality coming from the H2S.

Like the ability to add a laser cutter and digital cutter to the machine, there's also the option to add the Vision Encoder, which you'll need if you're going to be using this for professional product design or any dimensionally critical work. The Vision Encoder can be used for any print that needs 50-micron precision.

Through the software, there's also hole and contour compensation to assist with more intricate models. Again, the intelligent monitoring will stop if there is an issue. During the test, I tried to push the printer with a few excessive overhangs just to see what would happen, and the machine essentially paused as the print failure was detected.

As with the H2D machines, there's AMS Pro 2, and again, the new model is fully compatible with the original AMS and the AMS HT. You can also link several AMS modules together so you can extend printing to more than just four filaments, up to 16, and some people have even claimed it can be pushed further.

Bambu Lab H2S: Performance

Getting started with the H2S is as simple as any other Bambu Lab 3D printer, as it essentially comes pretty much ready to go. In this review, I'm looking at the Bambu Lab AMS Combo, so you get the 3D printer and the AMS Pro 2 to enable multifilament printing.

Getting it all set up is extremely straightforward. First, the packaging is stripped away, the AMS is popped on top, one tube connects the AMS to the machine, and then there's a data cable that also connects between the machine and the AMS. Once that's done, the activation key is popped into the back along with the power cable, and the machine is switched on.

After running through the initialisation and calibration process, which is all handled by the machine, you can then install the four filaments and get started with connecting to Bambu Studio and producing your first print.

As ever with this machine, there are a few prints just to get you started, and it shot through these in no time at all, with the 3D Benchy model looking exceptionally good, fine detail and a high-quality finish to all of the outer walls and using the default settings this took 33 minutes with all checks.

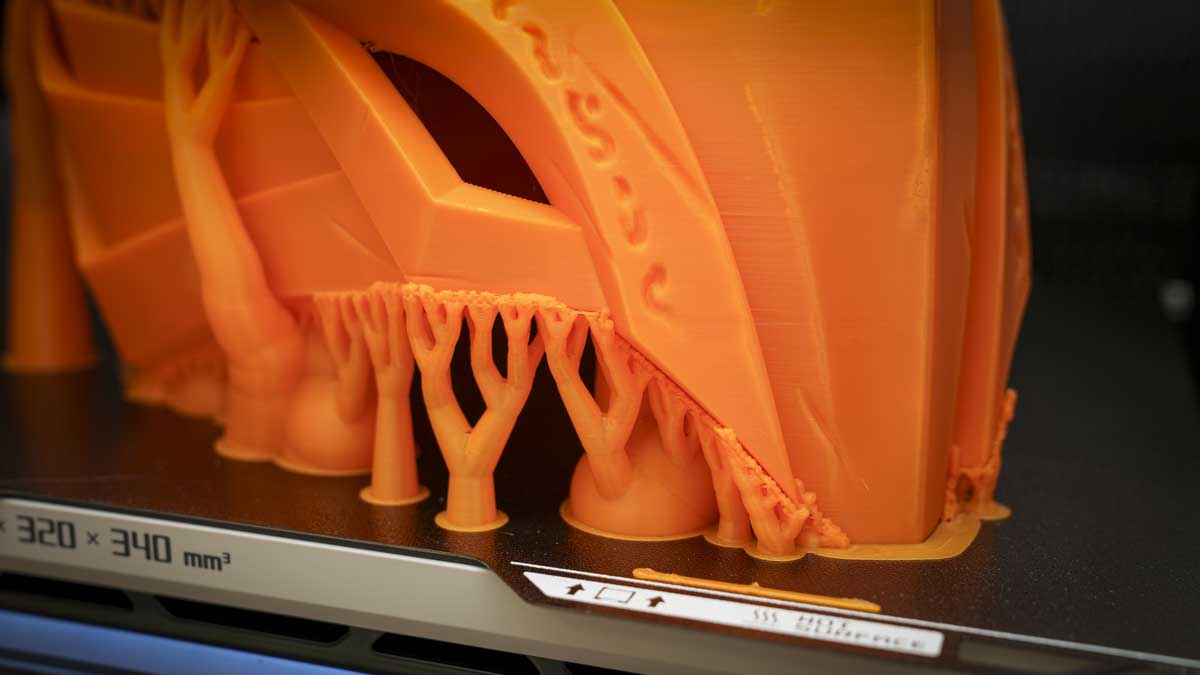

As I went through the test, there were some larger models to print to create a Shadow Force suit of armour, and this is where the machine really started to come into its own. The ability to print at a scale that is normally only possible with large-scale printers, combined with the high nozzle quality, meant that the end result had a surface cleanliness and consistency that you don't usually get with large-scale consumer 3D printers.

What I really liked was that, for quite a few of these large-scale prints, I did run out of filament partway through. However, the filament detection worked exceptionally well. As with many machines, it detected the issue, but what impressed me was that feeding in the new filament aligned perfectly, continuing the print from exactly where it left off. Adhesion to the print bed was sufficient that there was no movement or issue, even when the print had been left for a few hours in between filament changes.

For single filament printing, the print speed was exceptionally good, although at present, there isn't a huge array of presets for materials. So, if you are new to 3D printing and want high-speed prints, it is a little tricky to adjust the settings to get exactly what you want. However, if you are experienced with Bambu Studio, then delving into the quality, strength, speed, and support settings will enable you to fine-tune for those higher print speeds.

At those high speeds, the quality actually remains exceptionally good. While you can see a slight reduction in outer surface quality, for prototyping or quickly printing ideas, the quality is beyond what I've seen with most 3D printers of this type, size and price.

Going on to multifilament printing, again, the speed of the print was good. But, as with all other Bambu Lab AMS system printers, the volume of waste that gets kicked out of the back is quite extraordinary. So, while multifilament 3D printing is obviously a major pull for this machine, the fact that it still produces so much waste is a bit of an issue.

The quality of the 3D prints, however, is once again exceptionally good, with a high-quality finish and one of the best surface finishes for a multifilament print that I've seen. Multifilament print times are obviously slower on the H2S than compared with the H2D. That second nozzle makes a huge difference to both the amount of waste produced and overall duration. Still, because of the high-speed printing that is possible with the H2S, the speed was still good.

As an example, the Robo Tortoise four-colour print took just over 24 hours. On the H2D with its two nozzles, this print took only 20 hours. So, while there is a reduction in speed between the H2S and the H2D for multifilament prints, it isn't huge. The biggest difference really is the amount of waste produced.

As I ran through the test prints, I became more taken with this machine. While the single nozzle isn't as headline-grabbing as the dual nozzle of the other H2D machines, it's still exceptionally high quality and essentially makes this machine a top option for any designer looking to prototype or even run small production batches.

The quality of the casing and the size give you plenty of flexibility in how you use it, and the fact that it has that heated chamber enables you to use engineering materials such as nylon, ABS, and ASA. What really impressed me was that, across multiple prints, there were no real failures.

Bambu Lab H2S: Print quality

Target 25 = X: 24.88mm / 0.12mm Error | Y: 24.96mm / 0.06mm Error

Target 20 = X: 19.87mm / 0.13mm Error | Y: 19.90mm / 0.10mm Error

Target 15 = X: 14.87mm / 0.13mm Error | Y: 14.80mm / 0.20mm Error

Target 10 = X: 9.90mm / 0.10mm Error | Y: 9.80mm / 0.20mm Error

Target 5 = X: 4.90mm / 0.10mm Error | Y: 4.80mm / 0.20mm Error

X Error Average = 0.114

Y Error Average = 0.152

X & Y Error Average = 0.133

Fine Flow Control – Score of X

Fine Negative Features – Score of X

Overhangs – Score of 5

Bridging – Score of 5

XY Resonance – Score of 5

Z-Axis Alignment – Score of 5

Total Score – 29 / 30

Bambu Lab H2S: Final verdict

At the end of the test, there's no doubt that I'm impressed once again with this Bambu Lab machine. The H2S takes the scale of single-nozzle 3D printing up a notch, and unlike many other large-scale 3D printers, it offers a brilliant enclosed environment. This enables you to print with engineering materials, not just mainstream PLA that can be used with open frame machines.

Due to the CoreXY mechanics, you also have ultra-fast print speed, reliability, and the dimensional accuracy that comes with it. The test prints that came out of this machine were some of the cleanest I've seen, and at this scale and consistency, it's really difficult to match with any other model.

While the machine compares very closely to the other H2D models, just with a single nozzle, when it comes to print quality and speed, it takes a small leap forward for single-filament printing. Where it really comes into its own is in being able to print larger than any other Bambu Lab printer, and the scale of those prints is genuinely exceptional.

Although the prints Bambu sent me for testing were clearly optimised to show the printer at its best, I also tried it with other complex single-filament prints. It coped with contours, overhangs, and overall print quality exceptionally well. As ever, the AMS Pro 2 is a standout feature, and since I was reviewing the combo version, I was able to give that a proper test with the machine and once again it works exceptionally well, with the only downside being the amount of waste that is produced.

The quality of the multifilament print was again exceptional, and the fact that it's going through a single nozzle just gives you a little more real estate to print large. The full-scale helmet from the Cosplay armour I printed came out with exceptional quality and a support structure that was easy to remove.

One of the big points I would highlight while using this printer was not only the speed and scale, but also the quality of the surface finish.

Surfaces were exceptionally smooth, and when I printed the Autodesk Kickstarter test model I've been using for many years, it was almost a full 30 out of 30. The print surface was exceptional, and the only thing that let it down slightly was dimensional accuracy, although my thought is that, if I used the Vision Encoder, I'd likely hit that full 30 out of 30 for the first time.

Regarding the fine flow test, while I've had many 3D printers that can produce a very clean result, there are often slight signs of angel hair filament, with only the AnkerMake M5C previously producing a model with this level of cleanliness.

The other point I really like about the H2S is its simplicity. The base unit isn't expensive considering. If you're looking at this as an enthusiast or business user, the fact that you can buy the base unit for just over $1,000 and then upgrade all the way to the Laser Combo means it's relatively affordable and offers a solid upgrade path for the future.

At the end of the test, once again, Bambu Lab has demonstrated why it leads the market with its 3D printers, and the H2S single nozzle combo version reviewed here once again shows the level that all other 3D printer manufacturers need to aim for. However, with the likes of the Original Prusa XL and SnapMaker U1, while it's great to see a larger print area single nozzle machine it feels like there is a move now into multitool head options which could leave Bambu Lab behind in the technology stakes.

Should I buy the Bambu Lab H2S?

Buy it if...

You need a large build volume and speed.

Once again, this printer comes in the superb H2 form factor that offers a fully enclosed environment. This time, the single nozzle enables an even larger print area that should suit most home and small business projects.

You need precision for engineering projects

While a fully enclosed environment is nice for some users, if you're working in education or in the professional sector and need to print in engineering materials, this enclosed environment with its heated chamber is absolutely essential.

Don't buy it if...

You need native dual-nozzle multi-material

While single-filament printing is exceptionally good, if you need to use support materials as standard, then upgrading to an H2D will probably be a better idea.

You're a casual or first-time hobbyist

Starting with one of the best 3D printers on the market might seem like a great idea, but with so many superb printers at a fraction of the Price, it might be worth starting with a cheaper printer before investing in the H2S.

For more tech for your crafting studio , I've tested the best laser engravers.

Alastair is a photographer, filmmaker and tech writer who has been working in the publishing industry since the late 1990s. For more than 25 years he has covered photography, video and technology across Future's photography, technology and gaming brands. He runs a photography and video production company and lectures in TV and film. He can usually be found testing mini PCs or prototyping and prop building with the aid of 3D printing.

You must confirm your public display name before commenting

Please logout and then login again, you will then be prompted to enter your display name.