The AnyCubic Photon Ultra could be the future of 3D printing

Affordable desktop DLP technology

Sign up for breaking news, reviews, opinion, top tech deals, and more.

You are now subscribed

Your newsletter sign-up was successful

The AnyCubic Photon Ultra is launching via Kickstarter on September 14, introducing a typically expensive feature into the desktop printing space. DLP (digital light processing) technology is favored in industries like jewelry design and dentistry as it can create incredibly detailed prints much faster than SLA-type printers, but is usually far too expensive for most everyday consumers.

Texas Instruments help co-engineer a more affordable TI DLP Pico chipset, allowing AnyCubic to bring DLP technology to the desktop printing space for the first time, and at a reasonable price. The official retail price of the AnyCubic Photon Ultra will be set at $599, but there are perks to being at the front of the queue.

The first 100 backers on the Kickstarter will pay just $399, saving 33%, and the following 100 customers can still save themselves some cash with a reduced price tag of $499.

- Check out our guide for the best 3D printers

- 'Stupid mistake' caused 3D printers to take on a life of their own

- This is the best 3D modeling software of 2021

What exactly is DLP, and why should we care?

If you've dipped even a single toe into the world of 3D printing, chances are you've heard of AnyCubic – a well-established manufacturer of both FDM (fused deposition modeling) and SLA (stereolithography) printers. These are seen as the two most common types of 3D printers on the market, but we can generalize them to make things simpler.

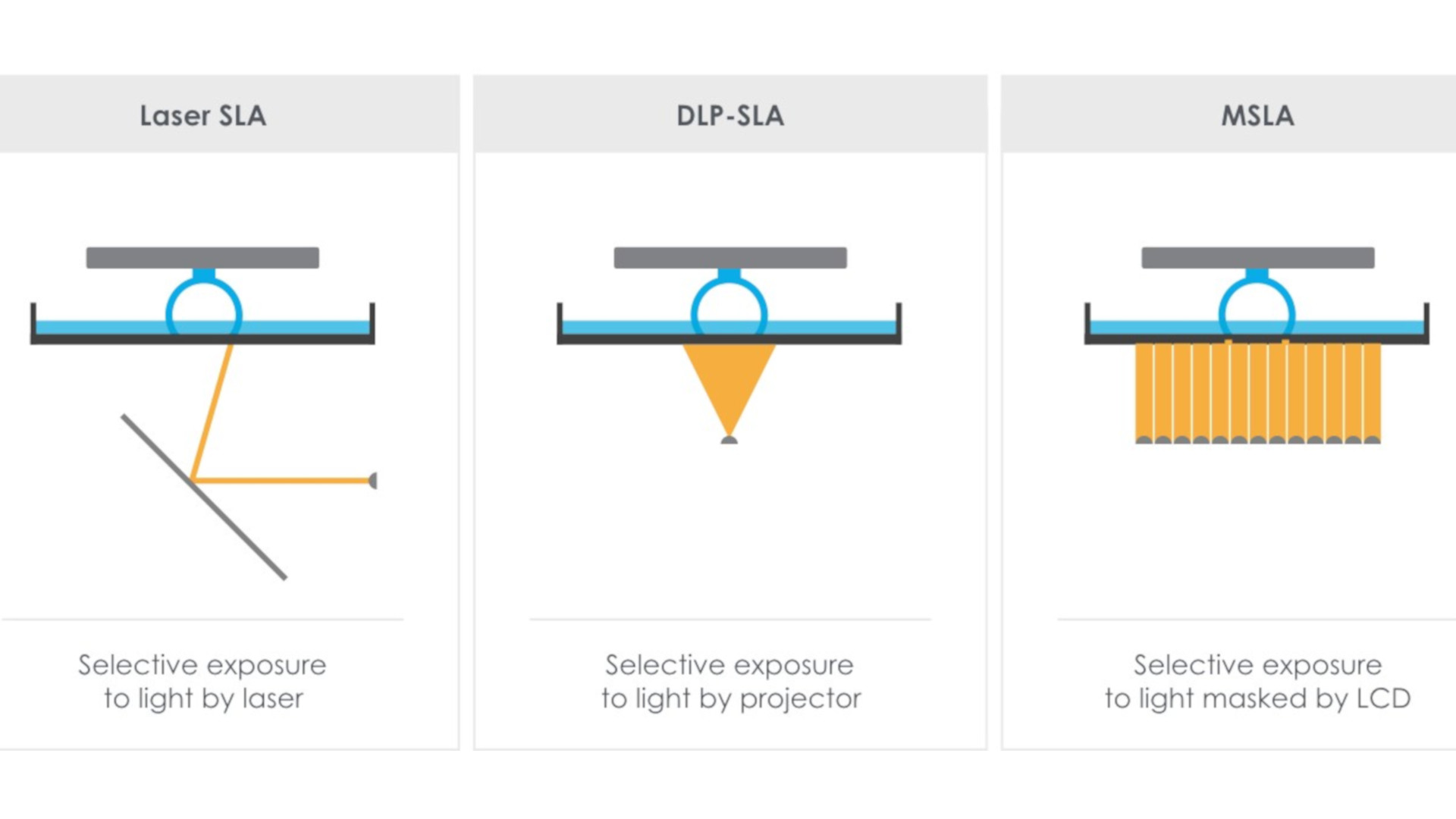

FDM style printers are more common and use a heated nozzle and a motorized X/Y axis to 'draw' a print layer by layer using melted filament, typically made from plastic such as PLA or ABS. SLA on the other hand, uses a vat of UV curing liquid resin, in which the print bed is submerged and flashes of UV light are used to rapidly cure the resin, point to point into the desired model. This is an oversimplification, as SLA printers actually use lasers combined with galvanometers to cure the resin, but you get the idea.

Resin-based printers are fantastic for picking up fine details and creating delicate prints like tabletop miniatures, while FDM printers can create larger models for things like props and prototyping. DLP technology is a version of resin-based printing that uses a specially developed projector screen, flashing an image of the entire curing layer at once which greatly speeds up the printing process.

What are the Pros and Cons?

An immediate benefit you'll see between DLP and SLA is speed, with DLP offering a much faster print time. Not only that, but you'll also see better longevity using a DLP style printer as SLA and MSLA hardware will need to have their UV panels replaced around every three to five months thanks to pixel burn out.

Sign up to the TechRadar Pro newsletter to get all the top news, opinion, features and guidance your business needs to succeed!

As DLP uses a projector, this isn't something you need to concern yourself with as it takes much longer for the hardware to fail, and when it does, it'll all go at once rather than gradually. This is another reason that industries prize it so highly, as DLP offers greater speed, more consistent quality over time and a longer product lifespan, making it preferable over SLA for batch production.

AnyCubic claims the Photon Ultra can run for more than 20,000 hours, and better yet, can deliver a quality that's "even better than 2K/4K monochrome LCD screen printers”, despite being rated for a 720p resolution.

Additionally, the Photon Ultra operates at 40% light efficiency, around 15 times higher than LCD models that typically operate at around 2.5-3%. Regarding power consumption, things are looking peachy there too, running at 12W with an average use of 8.5W, again, much better than a standard LCD/SLA printer. Finally, this style of printer doesn't require any cooling fans, resulting in a resin printer that's faster, quieter, more efficient and capable of extremely fine details.

It's not all sunshine and rainbows though. DLP printers can leave a lightly textured surface finish because of that projector, like a much finer grain similar to that seen on FDM prints. If you're printing something that can be sanded or even painted then this won't prove to be an issue, and even for small, detailed models, the grain is so fine that you'd need to be holding it very close to your face to even notice the surface texture.

Improvements are being made every day to 3D printing technology too, so this isn't information we have specifically regarding the upcoming AnyCubic Photon Ultra. There's every chance that the small cons to working with DLP have been smoothed out, and if those criticisms are fixed, DLP could very well replace SLA style printing in the coming years.

The AnyCubic Photon Ultra 3D printer specifications are as follows:

- Build Volume: 102.4 x 57.6 x 165 mm

- Layer Height: 10 microns

- XY Resolution: 80 microns (1280 x 720 pixels)

- Z-axis positioning accuracy: N/A

- Printing Speed: 1.5 s/layer

- Bed-Leveling: N/A

- Display: 3.5-inch touchscreen

- Third-Party Materials: Yes

- Materials: 405 nm UV resin

- Printer size: 222 x 227 x 383 mm

- Weight: ~4kg

Analysis: Its a good time to be a creative

Looking back a few years, the idea that you could print physical objects in the comfort of your own home felt like something out of science fiction. Now, we're spoiled for choice regarding the type of printers we can buy, and a wide range of sizes, filament types and technological breakthroughs means that there's never been a better time to jump into the creative making community.

Announcements for the next big thing in 3D printing (and other creative hardware like laser engravers and vacuum formers) could result in an increase of small businesses as technology that was previously restricted to large industries is downsized to sit on a shelf in our living rooms. You can even 3D print chocolate and other foods now, as well as materials such as wood and metal. Heck, you can even 3D print houses these days.

It's hard to say where the creative hardware industry is going, but consistent developments are bringing more affordable technology into the hands of everyday people. It's an exciting time, and who's really to say we won't see a Star Trek-style Replicator in our homes within our lifetimes? Sign me up scotty.

Jess is a former TechRadar Computing writer, where she covered all aspects of Mac and PC hardware, including PC gaming and peripherals. She has been interviewed as an industry expert for the BBC, and while her educational background was in prosthetics and model-making, her true love is in tech and she has built numerous desktop computers over the last 10 years for gaming and content creation. Jess is now a journalist at The Verge.