Why you can trust TechRadar

Getting started

As the box is removed it reveals the striking appearance of the Nobel. It's slim and tall, and the large UV shield along with the word Laser emblazoned across the base makes it look and feel like an object from the future, but one designed in the 1970s. Out of the box there are a few procedures to run through before the first print can be made.

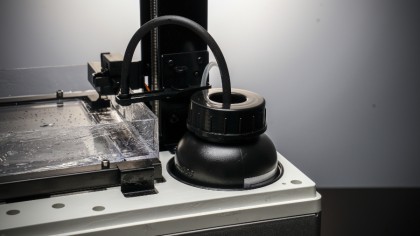

This starts with installing the resin bottle which simply drops into a purpose-made slot, and then the two tubes connected to the Nobel are push fitted onto the resin bottle – the other end is then clipped in place to feed the resin into the tank. The resin tank is removable for cleaning and simply slots into place, it's advised that this is replaced if it starts to discolour over time as this will ultimately affect print quality.

After everything is connected the machine can be switched on and configured. The first process is just to make sure the print platform is calibrated – this process is handled manually and involves loosening and tightening bolts and pushing down the platform, not too taxing or time consuming. Once completed you then use the Nobel's simple interface to select the initialise option, then pop the lid back on and leave the Nobel to fill the tank and prepare for the first print.

Printing

We used a USB stick loaded with a sample model file and used the control panel to quickly locate the models saved on the root of the stick – the navigation system makes it quick and easy to locate the files and once the model you want to print is selected it's then just a simple process of clicking OK to start the print process.

Here the next big difference between SLA and FDM printing becomes apparent. Our first test print which was a glass downloaded from the XYZprinting website took just over an hour – we ran the same model through the Cura for Luzbot Mini and it took just 15 minutes. However, the quality difference between the two was marked.

When it comes to printing your own models the Nobel uses XYZ's own software and is not compatible with any other software – however, the Nobel is designed to be straightforward. The XYZ software supports the standard STL file format and once a model is imported into the software you can then adjust the position and print quality easily enough.

Although the print model is actually printed upside-down in the printer, the model appears the right way up in the software. In the quick print settings there are three quality options, printing our test model using any of these produced consistently good results. One setting that we did find was essential after a couple of initial misprints was the brim option that just ensures the print bonds correctly to the print platform.

Sign up to the TechRadar Pro newsletter to get all the top news, opinion, features and guidance your business needs to succeed!

After a few days of experimenting we found that a slight tweak meant the majority of models would print cleanly. The overall print process is slow compared with the already slow speeds of an FDM printer, and you're also limited on the print material.

You can only print with the resin and this resin smells both when being printed and generally speaking, but this smell does however disappear once the model has solidified. Smell is also an issue with ABS but at least with the majority of FDM printers you also have the option to print PLA or similar, which only has a mild odour when printing and no smell at all when cold.

Once the print has finished unlike FDM printing where a knife can be used to simply prize the model from the base, SLA prints need a little more work. Gloves on and a tub filled with nail varnish remover (one with an alcohol content greater than 75%) and you're ready to remove the print.

The first step is to unscrew and slide out the platform, then a knife can be used to remove the print from the base – the model should then be placed into the tub. If you just give it a wash with water the print will remain tacky and slightly flexible for days. In the tub the print needs a good ten minutes wash in the solution before being removed and washed with water. You can tell when it's done as the surface texture changes from slimy to more solid and smooth. After washing it can then be left to dry and harden.

This might all seem like a faff especially when compared with an FDM print which is ready directly after printing, but then comparing the quality of the two prints, the higher quality of the SLA print is blatantly obvious.

Alastair is a photographer, filmmaker and tech writer who has been working in the publishing industry since the late 1990s. For more than 25 years he has covered photography, video and technology across Future's photography, technology and gaming brands. He runs a photography and video production company and lectures in TV and film. He can usually be found testing mini PCs or prototyping and prop building with the aid of 3D printing.