Here’s how your graphics card could make your 3D printer faster

Using the power of a GPU to go from design to 3D printing in seconds, not hours

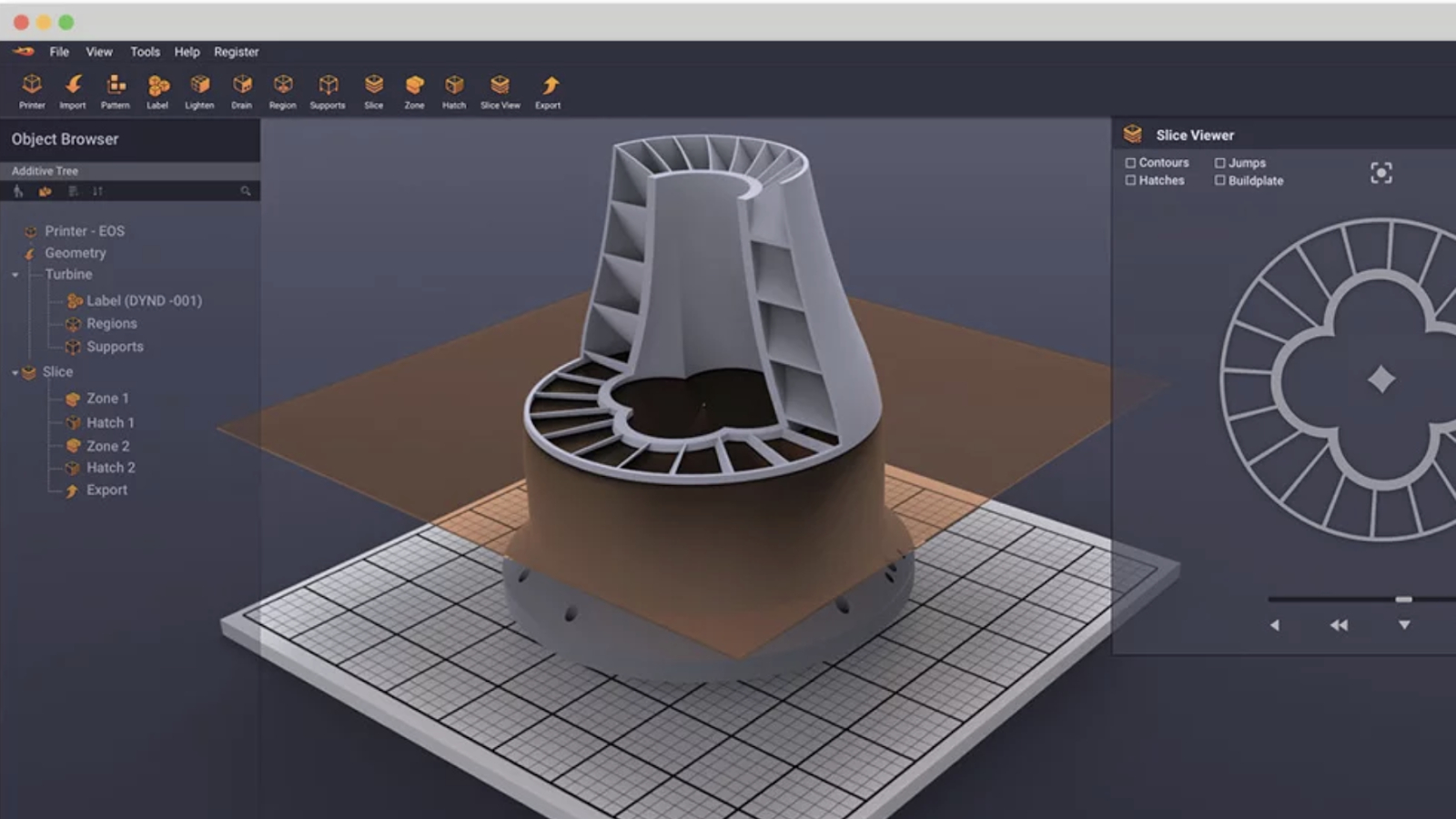

Dyndrite has been showing off what it describes as a state-of-the-art Additive Manufacturing Toolkit (AMT) which uses the power of a GPU to make 3D printing faster, and more streamlined in general.

AMT was unveiled by Seattle-based Dyndrite over at Formnext, with the company having built the toolkit around its Accelerated Computation Engine (ACE), which is a ‘GPU-powered geometry kernel’.

- HP adopts mobile phone-style contracts for 3D printing service

- These 3D-printed houses are made with a dirt cheap material

- These are the best 3D printers of 2019

The idea is to speed up build preparation and accelerate production in additive manufacturing – a fancy term for 3D printing – with the toolkit delivering a number of manufacturing-oriented capabilities.

That includes importing native CAD files swiftly – moving from design to the actual 3D printing far more quickly – and the toolkit boasts a fully integrated Python API which offers customizable scripting of interactive workflows.

Going from design to printing in seconds rather than hours leveraging the power of a GPU is clearly a big step forward, and Dyndrite compares it to Adobe revolutionizing dot-matrix printing with PostScript back in the 80s.

Dyndrite CEO and founder Harshil Goel told VentureBeat: “[Adobe’s] PostScript was a powerful computer language that essentially described a printer and the output. We are doing the same, describing a three-dimensional object for a 3D printer.”

Dyndrite notes that its ACE geometry kernel and AMT build processor were designed from scratch with a ‘first principles’ approach, using modern technologies to deliver on the production needs of customers across the aerospace, medical, automotive, energy and service bureau markets.

Sign up to the TechRadar Pro newsletter to get all the top news, opinion, features and guidance your business needs to succeed!

The hope is that this sort of tech could be extended to benefit a wider swathe of 3D printer users in the future, of course.

On-the-fly adjustments

The toolkit allows for the management of terabytes of manufacturing data, and the ability to print higher-order geometries such as splines, the company further observes. There’s also the ability to dynamically adjust parts on-site during the printing process, in order to achieve better quality (and indeed throughput).

Dyndrite notes that its toolkit allows for the preparation of files for any vector or raster 3D print process, and that includes Direct Metal Laser Sintering (DMLS), Selective Laser Sintering (SLS), Selective Laser Melting (SLM) and Binder Jetting.

The company further notes: “In addition, Dyndrite empowers hardware OEMs, and software developers to build next-generation, intelligent devices and applications.”

Dyndrite also announced that it has formed a partnership with Renishaw, a prominent firm in the world of metal 3D printing, to integrate its AMT into Renishaw’s QuantAM build processor.

Nvidia also chipped in here, observing that Dyndrite developed ACE using Nvidia Quadro RTX 6000 GPUs.

The graphics card maker said: “Today’s manufacturing hardware has outpaced traditional software, which can take hours when using seemingly powerful workstations to prepare files or terabytes of data for production. To efficiently process this amount of data, users need sophisticated hardware, software and GPU acceleration.

“ACE offers both a C/C++ and integrated Python API, enabling broad accessibility by both the traditional developer market, as well as end-users such as mechanical engineers and students.”

Darren is a freelancer writing news and features for TechRadar (and occasionally T3) across a broad range of computing topics including CPUs, GPUs, various other hardware, VPNs, antivirus and more. He has written about tech for the best part of three decades, and writes books in his spare time (his debut novel - 'I Know What You Did Last Supper' - was published by Hachette UK in 2013).