UK scientists have a smart plan to supply more respirators for coronavirus patients

OxVent project aims to scale production of ventilators as required in local areas

A team of engineers and medics from Oxford University and King’s College London are collaborating in a project to test and build respirators that can be produced in university labs and SME workshops, in a bid to help treat coronavirus sufferers.

The need for such ventilators to help those whose breathing is badly affected by the virus has been well-documented at this point, and the so-called OxVent project hopes to have a working prototype which can satisfy relevant safety standards in a ‘matter of weeks’, according to a report by Electronics Weekly.

- Razer joins battle against coronavirus by donating 1m surgical masks

- Best medical practice management software

- These are the best 3D printers of 2020

It would have to comply with MHRA (Medicines and Healthcare products Regulatory Agency) requirements, and if the initiative proceeds at the projected pace, the researchers believe a manufacturing network could be scaled up to produce the respirators within two to three months.

The hope is that universities, small to medium enterprises and manufacturing facilities would be able to produce these ventilators on assembly lines close to local NHS services, scaling to the needed demand for respirators in any particular area.

One of the OxVent team, Professor Farmery of Oxford’s Nuffield Department of Clinical Neurosciences, observed: “Ordinarily, to develop a medical device such as this would be a huge task, and would take years. We have designed a simple and robust ventilator which will serve the specific task of managing the very sickest patients during this crisis.

“By pooling available expertise from inside and outside the University, and making the design freely available to local manufacturers, we are pleased to be able to respond to this challenge so quickly.”

Dr Formenti, another researcher on the project, added: “Thinking beyond the current pandemic, we are also aiming to share the know-how and refinement of this relatively inexpensive approach with other countries.”

Sign up to the TechRadar Pro newsletter to get all the top news, opinion, features and guidance your business needs to succeed!

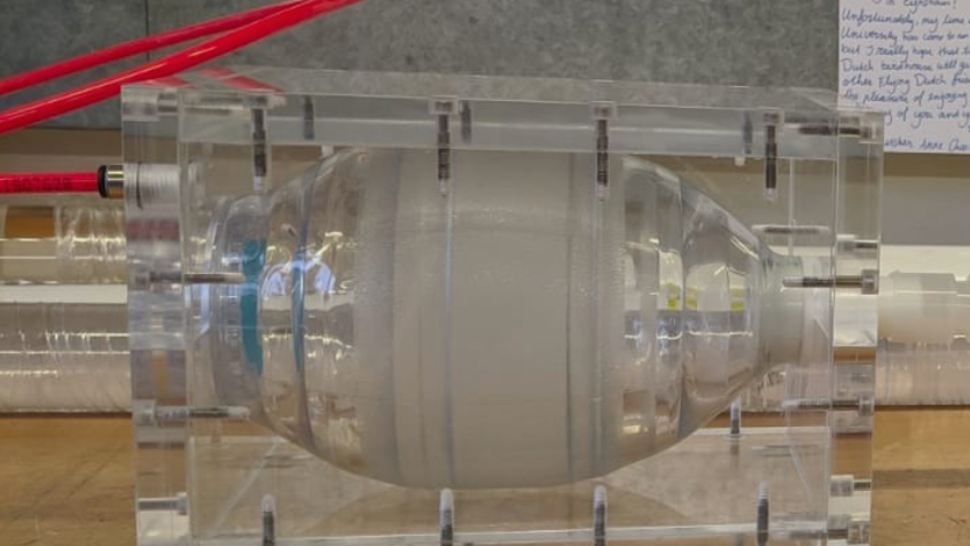

Prototype ventilator

The scientists have already uploaded a video of the results of their first week of working on the prototype ventilator, as you can see above. The accompanying blog explains: “The Ambu or bag valve mask is confined within a rigid perspex box. This box can be pressurised from a 4 bar line. When it is pressurised, the Ambu compresses, providing an inhalation. When the pressure is switched off, the Ambu re-inflates.”

This is one of many initiatives we’ve seen concerning producing medical equipment to help combat coronavirus, such as a call to produce an open source respirator, and Prusa kicking off a drive to make DIY 3D-printed face shields to help protect medical professionals who are treating patients with the virus.

Meanwhile, over in the US, we’ve also heard that the big car makers Ford, GM and Tesla have been given the ‘go-ahead’ to make ventilators, and make them ‘fast’, President Trump made clear on Twitter.

These car manufacturers have already been looking into how this might work, and indeed Ford could also be working with the UK government in producing necessary medical devices like respirators.

- Google and Microsoft offer free teleconferencing tools to combat coronavirus

Darren is a freelancer writing news and features for TechRadar (and occasionally T3) across a broad range of computing topics including CPUs, GPUs, various other hardware, VPNs, antivirus and more. He has written about tech for the best part of three decades, and writes books in his spare time (his debut novel - 'I Know What You Did Last Supper' - was published by Hachette UK in 2013).