3D printing: gimmick or small business opportunity?

3D printing opportunities for SMBs

In Makers: The New Industrial Revolution, Chris Anderson, author and former editor-in-chief of Wired magazine, writes: "The idea of a 'factory' is, in a word, changing. Just as the web democratised innovation in bits, a new class of 'rapid prototyping' technologies, from 3D printers to laser cutters, is democratising innovation in atoms. You think the last two decades were amazing? Just wait."

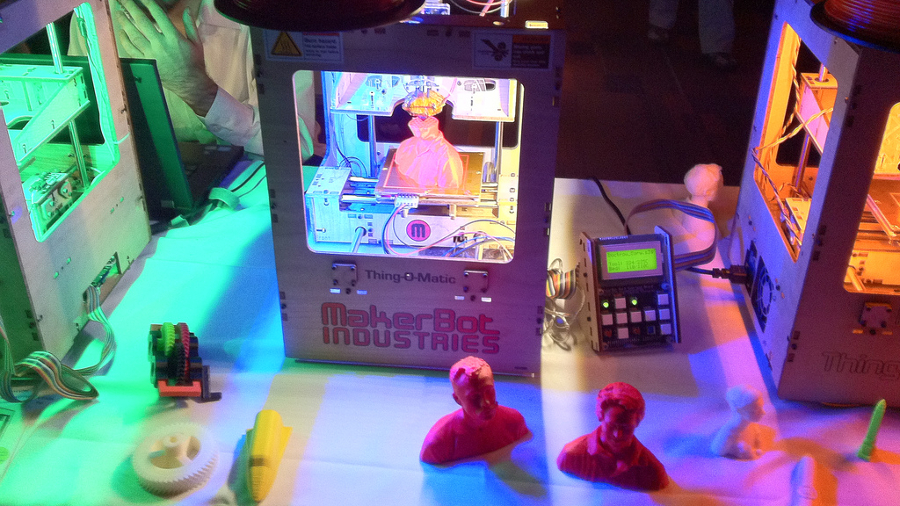

3D printing an object is not a new idea, as the concept can trace its origins back 30 years. However, 2012 was a pivotal moment in the technology's evolution, as the first affordable 3D printers began to appear. Being able to use inkjet printing technology to 'print' a 3D object has the potential to become one of the most disruptive technologies to appear for decades – and small businesses are the perfect vehicle to exploit this technology.

Subtractive past

In essence 3D printing turns manufacturing on its head. Traditionally products are created using the subtractive method, which includes cutting, gluing, forging and additional assembly to create the product. By contrast, a 3D printer can produce an object in a single operation, layer by layer. The object comes out of the printer fully assembled, including all its moving parts.

Subtractive manufacturing isn't going to die out overnight, as 3D printing has a long way to go before it becomes economical enough to replace traditional manufacturing techniques. However, smaller enterprises that perhaps develop and manufacture specialist products and components can leverage 3D printing technology now to deliver tangible advantages today.

And rapid prototyping has shifted to 3D printing to offer a much faster journey to market for a number of products. Here, smaller enterprises that could not afford to prototype some of their product ideas, can suddenly achieve just that with affordable desktop 3D printers.

Disruptive manufacturing

"By rapidly printing prototypes, manufacturers can significantly shorten the development lifecycle," said The Leading Edge Forum. "One example comes from Akaishi, a Japanese manufacturer of correctional footwear and massage devices. The company found that by 3D printing prototypes in-house, it could reduce lead-time of new products by 90% compared to its previously outsourced prototyping service. This allows its designers to have 100% confidence in a product's functionality before it ever reaches the customer."

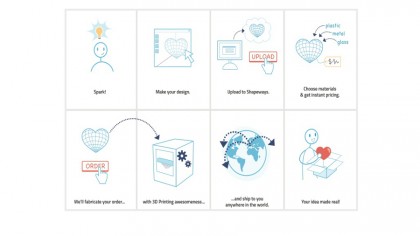

3D printing is growing as a home-based market, and also as an opportunity to deliver 3D printing services. Both of these sectors offer small businesses looking to innovate masses of scope to create new products and services. Already service providers such as Shapeways, Sculpteo and Thingiverse are showing how 3D printing could be a platform for new business services.

Sign up to the TechRadar Pro newsletter to get all the top news, opinion, features and guidance your business needs to succeed!

So is there a clear business case for 3D printing? "3D printing speeds up the design process and enhances this vital process," Paul Ryan, Group Marketer at Hobs Reprographics [www.hobsrepro.com] told TechRadar Pro. "Architectural models can be made in half the time of traditional methods and they are also half the price. More importantly, shapes that couldn't be made using traditional methods, such as complex curves, can now be made simply.

"In product design, 3D printing allows one-off high-resolution products to be created quickly. This is ideal for testing new ideas. 3D printing also helps convey complex information – 2D drawings of a plant room, oil rig or underground train station are challenging to interpret. 3D printing a scale model assists understanding as people can see all the information and move around it as if they are looking at the real thing."