TechRadar Verdict

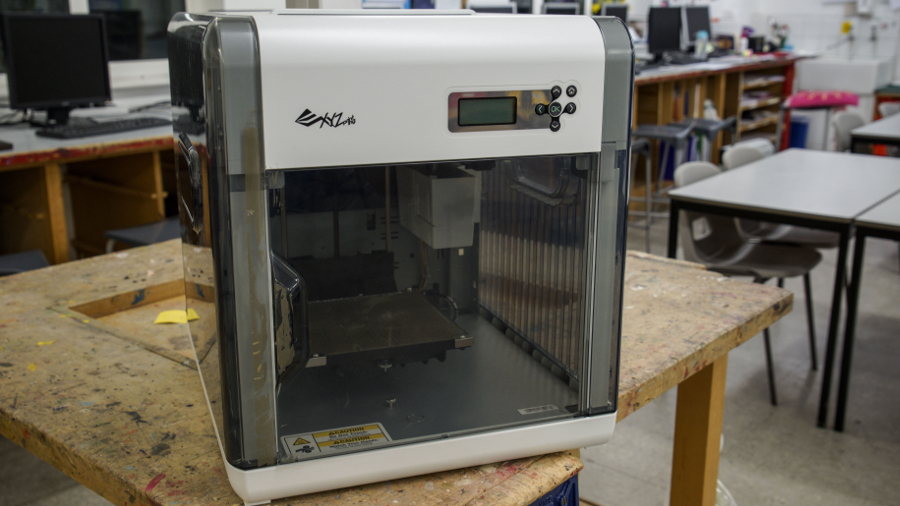

More suited to an educational environment than a home, the Da Vinci 1.0 is easy to set up and use, but models lack the finish of more expensive printers.

Pros

- +

Ready to use straight from the box

- +

Fully encased print head and platform

- +

Easy to use and replace cartridge filament

Cons

- -

Closed software and hardware system

- -

Only XYZprinting filament can be used

- -

Print quality isn't the best

Why you can trust TechRadar

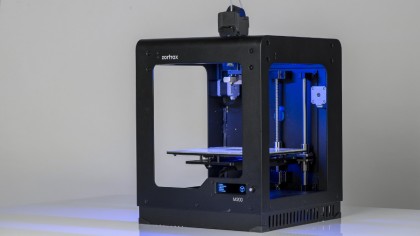

Zortrax is quickly establishing itself as a 3D printer manufacturer to be reckoned with. The M200 printer started life as a Kickstarter campaign and rose to prominence when Dell ordered 5,000 units.

Dell and many other backers of the campaign had obviously seen something in this startup that had piqued interest, and it only takes a short time with the M200 to realise why Zortrax has been set apart from many other 3D printer manufacturers that have appeared on Kickstarter.

The design bases itself around a movable X, Y direct feed print-head, with a vertical Z plane build platform, similar to that seen on the Ultimaker 2 series of printers.

- Buy Zortrax M200 3D printer at GoPrint3D

However, the Zortrax M200 features several design elements that set it apart from other printers. There's the perforated auto-levelling build platform, solid build quality, optional side and front covers, and overall high quality of parts.

The M200 is designed for use with 1.75mm filament and is compatible with most filament types on the market including PLA and ABS. It ships with Zortrax's own Z-ABS filament. It has a respectable build volume of 200 x 200 x 185mm and minimum layer height of 90 microns.

This 90 micros might seem low against the likes of the Ultimaker 2, but with an X, Y precision of 1.5 microns, the M200 is capable of producing prints that far surpass the quality of printers which boast a far smaller layer height option.

The Zortrax M200 sells for £1449 (or $2040 in the US, which is around AU$2630).

Sign up to the TechRadar Pro newsletter to get all the top news, opinion, features and guidance your business needs to succeed!

Build quality

There are few 3D printers that come close to the solid and quality build of the M200. The case is made from aluminium and as with the Lulzbot Mini is beautifully finished. However unlike the Lulzbot the M200 is fully contained with the power supply neatly integrated into the base rather than bolted onto the side. The black finish and solid construction give the machine a durable feel, and the size and weight mean that when in use any vibrations or movement during the print process are kept to an absolute minimum.

The case features an open side, front and top design, but if you prefer to add sides to minimise the effect of exterior elements or to stop stray fingers from wandering into the print area then there is an option to purchase these side covers for around £100 (or $100).

The printer uses a direct feed style print-head and features a 0.4mm nozzle to extrude the 1.75mm filament. As with the Ultimaker printers, Zortrax is moving away from the RepRap origins so there are few 3D printed parts incorporated into the build, so unlike the Lulzbot models, all parts are either high quality machined metal or injection moulded plastic.

However, almost in the same way that a tailor will leave a few hidden signs to show a suit is handmade, many 3D print manufacturers still use at least one 3D printed part in their machines, and on the Zortrax that part is the spool holder that mounts onto the back of the printer.

Bearings, lead screws and even stepper motors all appear to equal the quality of the rest of the build, and absolute precision is definitely at the heart of this printer's mechanics.

As is becoming increasingly common the M200 gives you the option of printing tethered from the Z-Suite Software or direct from SD card (an SD Card is provided). The small LCD screen and dial enable you to quickly navigate settings or print direct from card, and the most recent update to the firmware increases the speed and usability of the simple interface. This makes it intuitive and easy to use, both for printing and general maintenance such as swapping filaments.

One of the biggest differences between the M200 and the majority of other 3D printers at the moment is highlighted in the build platform. This has several features that really show the in-depth thought given to the technical aspects of printing, addressing issues such as how to get the platform level, heated, and the model to stick.

The platform is of the heated type which means that a huge selection of filaments can be used, and Zortrax uses its own formulation of popular filament types that can be bought through the firm's website. These are a reasonable price and excellent quality.

The big difference in the build platform is that it is perforated – this design cuts out the need for tape or glue as the holes create sufficient area for the molten filament to adhere to. In our testing we didn't experience a single print that failed to stick to the build platform.

Alastair is a photographer, filmmaker and tech writer who has been working in the publishing industry since the late 1990s. For more than 25 years he has covered photography, video and technology across Future's photography, technology and gaming brands. He runs a photography and video production company and lectures in TV and film. He can usually be found testing mini PCs or prototyping and prop building with the aid of 3D printing.