Why you can trust TechRadar

Print quality and options

Over four weeks, the Original Prusa i3 MK3S was running almost continuously; test models, stress tests, prototypes and long haul prints.

Utilising the standard settings on Cura 4.0 and PrusaSlicer 2.0 the results and reliability were impressive.

The first set of tests utilised Cura 4.0 and the 3DBenchy stress test. The results at all bar the finest settings produced excellent results and some of the best I have seen from an FFF printer.

I started with the Extra Course option; when this works, it's ideal for realising ideas quickly. More commonly it just ends up as a spaghetti mess.

Here the MK3S handled the Extra Course mode exceptionally well, taking just over 30 minutes to print 3DBenchy. The final model was a little course, but then that's what this mode is for.

The majority of the other setting produced progressively better prints, or improved on print times, with the only exception being the Extra Fine quality which failed to print on each occasion. Whether this was the Cura or the printer, I'm not sure.

I ran the same test through the PrusaSlicer software, and the results were pretty evenly matched.

The three quality settings I was most interested in seeing were Draft, Quality and Ultra detail.

First up was the 0.3mm Draft this took just over an hour to print the 3D Benchy model, and while you could see the stepping on the top ridge of the hull the overall quality was exceptional.

Increasing the quality options simply increases the quality of the print with the speed options for 0.20 and 0.15 only saving a few seconds on each print. However, resonance is visible in the faster prints.

Utilising the highest quality print option and print times extended to around 7 hours and 40 minutes. The overall quality was excellent, but there was quite a bit of very fine stringing which needed to be lightly brushed from the model.

Overall the print quality and results were outstanding. Part of this could be down to the Gyroid infill pattern which is quite unlike that produced by other Slicers.

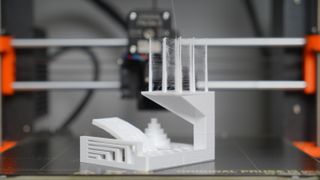

The next check was to utilise the Autodesk Kickstarter test, which has become a benchmark for testing the quality of 3D printers.

Again, as with the 3DBenchy test, the results were impressive. For each of the quality tests, I used the PrusaSlicer 2.0, which gave the best results and proved to be a powerful application.

The filament used was the eSUN PLA + which is recommended.

There are seven parts to the test, and each is designed to evaluate the accuracy and quality of the printer.

Dimensional accuracy - score of 5

In the model there's a stack of cylinders in decreasing diameters, each of these is measured in first the X and then Y axis. The results are then compared with the target measurement. The model produced the following average of the X and Y measurements.

- Target 25 = X: 24.96mm / 0.04mm Error | Y: 24.90mm / 0.1mm Error

- Target 20 = X: 19.97mm / 0.03mm Error | Y: 19.96mm / 0.04

- Target 15 = X: 14.97mm / 0.03mm Error | Y: 15mm / 0mm Error

- Target 10 = X: 10mm / 0mm Error | Y: 10.01mm / 0.01mm Error

- Target 5 = X: 5mm / 0mm Error | Y: 4.97mm / 0.03mm Error

- X Error Average = 0.076

- Y Error Average = 0.036

- X&Y Error Average = 0.056

Fine Flow Control - score of 2.5

Measuring each of the spikes and it shows a length of 40cm and although there's some fine stringing going on towards the top of the print it's still an impressive result.

Fine Negative Features - score of 5

With the printer storming through the test the Negative features test I thought would be simple, however out of the five pins only two were easily removable, looking at the base of the 0.4mm pin and there appeared to be a lack of adhesion. With a little pressure the 0.2mm pin popped out, with quite a bit more force the 0.3mm popped out, and the 0.4mm was welded in place.

Overhangs - score of 3

Always troubling overhands can be a real issue. The Original Prusa i3 MK3S did an excellent job with a smooth step at 45º and 30º, at 20º some visible stringing was apparent, and that was enhanced at 15º.

Bridging - score of 5

Like overhangs without support, bridges can be troublesome, but here with the distance required by the stress test, the Original Prusa i3 MK3S didn't have an issue, bridging all with ease.

XY resonance - score of 2.5

Look as hard as you might, and there's just no sign, it looks like the alterations to the extruder position have done the job.

Z-axis alignment - score of 2.5

The final check looks at the Z-axis alignment, essentially checking for visible layering on the pillar. Here there's nothing to be seen.

Adding up the totals gives a final score of 25.5 out of 30.

Finally, once the main tests were over and had ultimately proved that the Prusa i3 MKS3 is one of the best printers on the market, I tried out a few of my own models to see how it would perform.

When selecting a quality setting to print with, I tend to opt for the one that gives me the best balance of quality and speed. If you have a finely tuned printer, then you'll only be able to tell the difference if you look closely at the print.

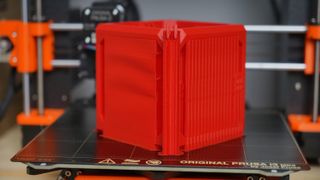

The first print is part of a teleprompter I built some years ago. The model is huge and usually takes between five and ten hours to print. It's pretty simple but highlights some issues with accuracy on some printers. It's also a great way to see how the printer performs over a long period.

Utilising the standard Quality option for the test the MK3S handled the print well, brass inserts fitted perfectly with a bit of heat, and there was no issue with print quality.

The next test was a 360 GoPro rig; this can be a real challenge with large overhangs that require support. Again utilising the same quality settings the printer managed an excellent result. I printed this model without supports just to see what would happen and the result was an obvious mess.

Final verdict

There's a reason that the Prusa i3 has become such an icon of the 3D printing world.

The design lends itself to being upgraded, adjusted and experimented with. It's open, and all the parts are accessible so you can see how it works, if you want to, you can even build your own.

While the design might not bother those from the 3D printing community, those external to it may have an issue with the DIY aesthetics, however, refined they are.

In truth the machine has evolved, it may look like it's been built in a garage, but design, function and quality are all exceptional. From the quality of the components through to the exceptional prints.

The Original Prusa i3 MK3S is so good that it rivals if not beats many printers that are well over twice the price.

This is only the single extrusion machine, but being Prusa an upgrade to dual or multi extrusion is, of course, available making it more upgradable than most other machines on the market.

As there's a vast community of users, the machine can be hacked and upgraded in countless amazing ways, but there are drawbacks.

The machine is open, so if you have children or pets, then fingers or noses are drawn towards the hottest parts of the machine, especially it seems sweet smelling PLA. This means that while it's an excellent choice, it may not be suitable for homes or educational facilities where children or pets can get easy access.

The design is very workshop, something I love, but that lack of style and aesthetics will put the chic design studio types off.

However, the Original Prusa i3 MK3S does two things no other printer can do. Firstly it's the cheapest 3D printer on the market that can produce this quality of print consistently. Secondly, it's the best FFF printer on the market and is the printer by which all other 3D printers will be judged.

If you're looking for your first 3D printer, you like to tinker, or you run a business and want a good reliable machine then look no further than the Original Prusa i3 MK3S.

- We've also highlighted the best 3D printers

Ali Jennings is the imaging lab manager for Future Publishing's Photography portfolio. Using Imatest Master and DxO Analyser he produces the image quality tests for all new cameras and lenses review in TechRadar's cameras channel. Ali has been shooting digital since the early nineties and joined Future's Photography portfolio back in 2003.

How to watch Liège-Bastogne-Liège 2024: live stream men's cycling online from anywhere

A key Apple app is rumored to be getting a major upgrade in macOS 15

Intel's formidable 288 core CPU now has a proper family name — Granite Rapids and Sierra Forest are Xeon 6 processors but is it just becoming too confusing?