PC water cooling guide: all you need to know

Keeping your PC cool and quiet is now cheaper and easier

The coolant (let's just call it water for simplicity) is poured into a reservoir or tank, which in turn is connected to a pump unit. The reservoir level will need checking and topping up every once in a while, as water will evaporate thanks to the heat, and it's a good idea to drain the whole thing and clean it every six months or so too.

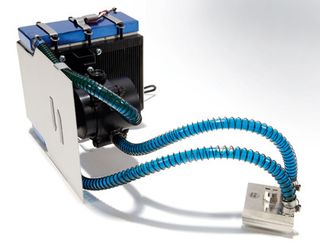

The pump pushes the fluid out through a network of pipes to a block of highly conductive metal, usually made from copper or aluminium. This block has one finely milled side, which is clamped on top of the CPU - or GPU or Northbridge controller chip on older motherboards - and has narrow channels running through its core. The water flows through these channels, absorbing heat from the rest of the material, and then exits the CPU block on its way to a radiator.

At the radiator, the water is pushed through a network of even narrower channels, which are cooled by having air blown over them by a fan. It is possible to build a passive watercooling system, like the Reserator V2 mentioned above, but they tend to be larger in order to give the water enough time to cool down to match room temperature, and are less efficient. The water then flows back to the reservoir and begins its journey again.

Efficiency is king

The obvious flaw with watercooling is that even with a fan assisted radiator, you can't cool the fluid below air temperature. It's possible to find a radiator that's connected to a more sophisticated heat exchanger, like a TEC unit or a compressor of the type more commonly seen in refrigerators. These are relatively expensive, though, and increasingly hard to get hold of as they fall out of fashion.

Just because a normal watercooling system can't drop the core temperatures below zero though, doesn't mean that you might as well stick with an air cooler - the important point is that they're very efficient, keeping chips colder for longer while they're working under load, and getting them back down to room temperature faster once they start to idle.

For most systems, there are two ways of improving the cooling capacity: you can either increase the fan speed by the radiator or turn up the water pressure on the pump control. Either option will increase the noise levels, and it's important to read reviews and get recommendations before you invest in a potentially pricey system.

Get daily insight, inspiration and deals in your inbox

Get the hottest deals available in your inbox plus news, reviews, opinion, analysis and more from the TechRadar team.

I've tested pump units that are not only noisier than any standard system fan, they have a similar effect on the bladder to standing beside a large fountain too. You don't really want that if you find yourself stuck for eight hours with a particularly intransigent raid leader, do you?

Designed for life

With those parameters, of course, there are lots of permutations when it comes to the kit you can buy, although the choice is a lot more limited than it used to be in the past. Even quietpc.com, which pioneered sales of watercooling components no more than a few years ago, has a relatively small selection of Zalman kit on its site now.

Only really niche specialists, such as watercoolinguk.co.uk, carry much in the way of choice of components if you want to build a system yourself these days.

It's not essential to get parts for an entire system from the same manufacturer, but several websites carry a lot of XSPC gear either as separates or complete kits, which makes it one of the best brands to watch out for.

In terms of design, the most popular variants that have been settled on are self-contained CPU coolers or reservoirs that sit inside two or three drive bays at the front of the PC, which have a built in pump and controls that become part of the front panel.

Apart from adding a certain je n'ai sais quoi to your machine, it means the whole thing is contained within the case. Otherwise, you'll need to pipe water out of the back of the case to cool it.

Pumping action

Drive bay pumps tend to be noisier than external units, because they use smaller motors and vibrations will be magnified by the case itself, but they do have the advantage of taking up less room and leaving your PC relatively portable still, if somewhat heavier than before. There's also less chance of tripping over external units and spraying coolant on the cat (there's a joke right there - Ed).

Connecting the various parts of a watercooling system up is generally straightforward. Most are designed for the hoses to sit over rubber seals and be locked into place with jubilee clips.

What's important to remember when designing your system is that if you're planning on using a watercooler for overclocking your CPU, you may need to consider heat at other points on the motherboard too.

Processors from AMD's Black Edition series or Intel's Extreme Editions have unlocked multipliers which means they can be tweaked independently of other components, but for anything else you're going to be raising bus speeds across the board. That means you might want to add in watercooled heatsinks for your RAM and graphics card, which is considerably trickier than just chilling a processor.

For a start, you'll need to get the flow of water around the inside of your case right, running it over cooler components first and possibly adding a second radiator to drop the temperatures between - say - the GPU and CPU. It's a bad idea to take fluid that's already warmed up and run it over a cooler component if you're trying to reduce its temperature.

At the very least, you'll need a double width radiator to disperse the heat. These usually bolt over two fan slots at the top of the case and are slightly noisier than a single unit.

In principle, that's all there is to watercooling. Every system is unique, and it's a good idea to clip back errant hoses with cable tidies to stop them snagging if you need to pull out a part, but it's really not as complex as you might think, and modern systems are usually well-designed when it comes to preventing leaks.

Worth the pain?

Is it actually worth it, though? After all, a full kit can cost over £200, and you'll need a decent motherboard to push the CPU to any great extent too.

Some people seem to think so. All Cyberpower PCs, for example, are sold with watercoolers as standard. We asked production manager David Scott why that is: "Any water cooling cooler we have used will allow you to overclock a PC," he said.

"And the price of self-contained units are practically the same price as a decent air cooler anyway. The risk of water damage on a self-contained unit is very low, and because of this most manufacturers will guarantee the warranty on the parts affected by a leak. Custom built kits look amazing and you can get top end performance that only cryogenics (LN2 or Phase-Change) will beat."

How good is it? Well, it can certainly help to close the gap between AMD and Intel, for example. Using a watercooled rig to overclock a six core Phenom II 1100T (£200) to 4GHz, we brought it within 16 per cent of a top-end Core i7 2600K (£260) in gaming and video encode tests.

More impressive, however, was taking a £50 Athlon II 255 chip and giving it the water treatment and a few BIOS tweaks, had it running at 3.9GHz and easily matching any dual core Phenom II in the benchmarks.

That's performance enough to justify the cost of a self-contained unit, and potentially a great way to revive an ageing PC.

Ultimately, though, watercooling isn't about cost. It's about the joy of building and tweaking a PC and knowing that, in these days of superfast stock CPUs and tablets, there's still space to create something unique.

Something slicker?

If the main reason you're interested in watercooling is to reduce the sound of noisy fans, why not make your PC completely silent by submerging it in oil?

Stripping your system components of all moving parts and then sinking them to the bottom of a tank of mineral oil is a well-known way to achieve the most consistently low temperatures possible. The oil itself is non-conductive and doesn't harm components, and so long as the tank is large enough that heat is shifted away to the surface by natural convection currents, you won't need any pumps.

That does mean that oil is no use for extreme overclocking, because you can't chill components below ambient room temperature. But for a media centre, say, it's near perfect - except for the fact that any peripherals that plug directly into the motherboard are likely to make a bit of a mess on your living room carpet.

Oil cooling has been around for ages. The early Cray 2 supercomputers, for example, were kept at stable temperatures using this technique and US start-up Green Revolution Computing is pushing the technology for data centres, where it can be considerably cheaper than CPU fans coolers and banks of air conditioning.

While mineral oil is preferred for this type of heat management because of its non-corrosive nature, it can be hard to get hold of in the UK in large enough quantities to be practical.

Emptying individual bottles of baby oil into a 30 litre tank, for example, would soon get quite expensive. Other oils can be used, but the drawback is usually that they smell. Vegetable oil, for example, makes a fine coolant - so long as you don't mind your PC smelling like chips.

Something a little colder?

The big daddy of component cooling remains, of course, liquid nitrogen, or LN2 to its friends.

Contrary to popular belief, liquid nitrogen is not the coldest fluid known to man, that honour goes to helium which has a boiling point 100 degrees lower than that of LN2, but nitrogen is the PC enthusiast's coolant of choice because it turns into a gas at -196 °C and is relatively cheap and easy to purchase - providing you have a cryogenically safe Dewar flask and convince your local industrial chemical supplier that you're capable of handling it safely, that is.

Using LN2 to sub-zero temperatures, hardcore overclockers are able to hit clockspeeds of over 8GHz on a Cedar Mill Intel Celeron chip. The cooling effect is achieved by attaching a flat bottomed tube, or 'pot', in the heatsink position which can be filled with LN2 just before the CPU is switched on. It's not much use for day-to-day cooling, as even a full pot will evaporate in minutes.

While it sounds simple, there's a lot more to it than that. For a start, the engineering of the pot has to be immaculate. Any minute ridges on the surface of the CPU or base of the pot could cause the chip to crack when the LN2 is poured in. Then there's the problem of condensation: as water forms on the surface of the components, it can create short circuits and damage the system.

In fact, it often takes months of preparation to get a board and CPU working stably with LN2. Practice runs with mechanical phase change machines at slightly higher temperatures will be needed to test the thresholds of the equipment, and motherboards have to be customised with soldered in resisters to get the kinds of voltages that BIOSes just don't allow, but are needed to go several gigahertz above the operating limits.

As far as we know, there are no recorded episodes of overclockers injuring themselves by using LN2, and when handled correctly the liquid itself can be quite safe.

Arguably, the best way to indulge in LN2 overclocking would be completely naked, since the liquid itself boils off of skin before it can do any harm - thankfully though, there are no public records of naked overclockers, although a YouTube video is bound to turn up now.

That said, it's not something we'd advise you to try without a lot of experience in both handling dangerous chemicals and overclocking PCs. Even the experts are shaken by LN2's reputation and terrifying characteristics, and many of the best stick to slightly less challenging techniques like using dry ice for equally impressive results.