Why you can trust TechRadar

Build quality

Built around a metal framework and bolted together, the build quality really comes down to a simple matter of how well you can construct the thing, obviously enough. Ooznest has provided everything you need, so build it well and you'll get a decent quality printer, but rush through the process and the printer and quality of the prints will ultimately suffer.

As far as the parts go there are several key components that make up a 3D printer – namely the frame, electronics, extruder and hotend.

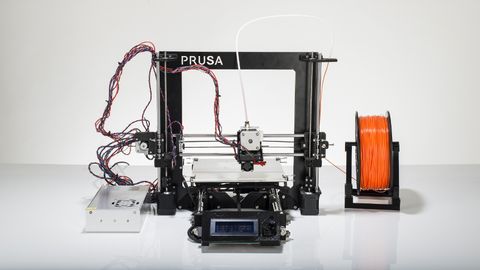

Starting with the frame the kit features a good quality pre-machined metal Prusa i3 frame to which everything – plastic printed parts, stepper motors, electronics and other components – gets bolted to.

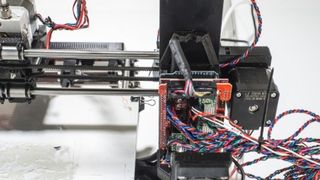

At the heart of the printer is the RAMPS 1.4 control board which is the latest iteration of the board and a popular choice. This integrates the Arduino MEGA2560 board and stepper drivers and has a proven track record for reliability. The Hexagon all metal hotend and Bulldog Lite extruder are all really good quality parts especially at the price. This is a 12V setup that enables the use of 1.75mm filament through the Hexagon's 0.4mm nozzle, a great starting point that can be upgraded as you become more familiar with the technology.

Ooznest modifications

Ooznest has made a few modifications to the standard Prusa i3 design when it comes to its kit. Some of these changes to design have been developed by the Ooznest team whilst others are popular modifications made by the Open Hardware community.

These modifications make a big difference to the final print quality when compared with the original Prusa and include a Z-axis frame brace – two simple brackets that sit under the main vertical of the metal frame to ensure that the structure is square, and this helps to reduce frame wobble during printing.

To avoid any issues caused by bowed threaded rods, Z-axis isolators have been incorporated to keep the X and Z-axis separated, with a mechanical endstop also incorporated into the assembly which makes adjusting the Z-axis height much easier.

As with other Prusa i3 mods the power supply and filament reel are separate to the main body of the printer, and there are further mods that you can find on Thingiverse.com to update the Prusa i3. Of course these are parts that you can upgrade yourself once you have the printer up and running.

The build platform dictates the size of print that is possible once the printer is complete and this kit features a 200 x 200 x 175mm (W x D x H) build area, with the width being reduced by 5mm due to the bulldog clips that hold the Borosilicate Glass Build Plate to the heat bed. This size is on par with the Ultimaker 2 and Lulzbot Mini.

The combination of the Hexagon hotend and Bulldog Lite extruder enables temperatures of up to 295 degrees Celsius – this means that standard materials such as ABS and PLA are fully compatible. It should also mean that you'll be able to print with other materials such as nylon, although that hasn't been officially tested.

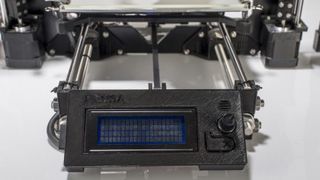

An LCD control board finishes off the design and this enables you to quickly adjust printer settings including fine tuning the X, Y and Z-axis positions, heat of the hotend, fan speed, and – if an SD card is inserted into the side – direct card printing. These are all high-end features that add to the ease of use.

Scientists inch closer to holy grail of memory breakthrough — producing tech that combines NAND and RAM features could be much cheaper to produce and consume far less power

Google adds biometric verification to Play Store to keep your in-store wallet safe

Quordle today – hints and answers for Wednesday, April 17 (game #814)