The digital manufacturing revolution gathering pace in the UK

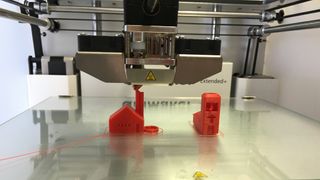

3D printing offers manufacturing firms the chance to transform their production methods

The digital revolution is progressing apace, powered along by technologies such as big data, analytics, AI, machine learning, automation and the Internet of Things. And the manufacturing sector is now beginning to embrace a transformation of its own. A transformation by a technology with the potential to digitise the entire production process and supply chain.

3D printing is in the process of turning the world’s $12-trillion manufacturing industry on its head. It is changing the way we conceive, design, make, distribute and consume just about everything. As a digital technology, it offers manufacturing firms the chance to transform their production methods.

And the good news is that Britain is ideally placed to play a leading role in the development of this thoroughly disruptive technology.

- We've also highlighted the best 3D printers of 2018

Full circle

3D printing is rapidly generating a whole new model of industrial production. It is updating manufacturing for today’s hyper-connected digital economy – while at the same time, bringing back the benefits of long-disused methods.

Think back for a moment to a time before the first industrial revolution, when products were designed and produced by artisans. They were bespoke, made on-demand, and intended for local consumption.

Then came the first two industrial revolutions, which were powered by steam and electricity. They put an end to this model, by separating out design from manufacturing.

However, the two functions remained geographically co-located – that is, until the age of IT and the internet came into being. The third industrial revolution connected the world, doing away with the need for physical proximity between design, production and consumption. So the current manufacturing paradigm has become: produce goods where the costs are lowest, and transport them to markets where there’s demand.

Are you a pro? Subscribe to our newsletter

Sign up to the TechRadar Pro newsletter to get all the top news, opinion, features and guidance your business needs to succeed!

It’s a model that places enormous distances between manufacturing and consumption, which has given rise to long and complex supply chains. These are not just costly; they’re also rigid, making them ineffective at matching supply and demand. And they require goods to be moved around the world, which is clearly damaging to the environment.

But now, a new digital manufacturing model is emerging, spearheaded by 3D printing. It is reclaiming the power of the custom production of the pre-industrial age, and applying it to the digital era – all on a global scale.

Digital production technology is moving us from mass production to mass-customisation. It is accelerating design, innovation and production, reducing manufacturing costs, and driving more flexible supply chains. Advances in metals 3D printing technology, such as HP’s recent announcement with Metal Jet, are accelerating the fourth industrial revolution by allowing the mass production of mechanically functional parts.

Green credentials

3D printing is also improving the sustainability of manufacturing on a number of fronts.

Firstly, it has the potential to drive vast supply chain efficiencies. Modern supply chains are responsible for around 22% of energy-related greenhouse-gas emissions. A product as simple as a shoe can contain 25 or more materials, all sourced from different parts of the world.

But thanks to digital production, footwear retailers can now make their own shoes instore. Similarly, a furniture store could print your preferred coffee table design, while automotive manufacturers can make the components they need at their factories.

All of which means fewer containers loaded onto enormous, diesel-powered freighters; and fewer lorries clogging up the motorways and polluting the air. That’s far more cost-efficient – and considerably more sustainable.

Traditional manufacturing methods are also adept at wasting materials. They stamp, carve or cut raw materials into finished products, resulting in up to 30 pounds of waste for every pound of product made. By contrast, 3D printers can achieve 98% material efficiency when producing finished parts.

Finally, production scale can be drastically reduced using digital production. Instead of needing to make millions of components to drive economies of scale, items can be made specifically to demand, which all but eliminates overproduction.

As a result of these advantages, 3D printing could decrease CO2 emissions by up to 525 million tonnes by the year 2025. That’s the equivalent of taking more than 100 million passenger vehicles off the road.

Coming of age

Yet despite its dramatic benefits, there is a nagging perception in some circles – even within the manufacturing sector – that 3D printing is yet to reach full industrial maturity.

But this simply isn’t the case. Digital manufacturing is already being employed as a large-scale, customised production method.

The Royal Navy, for instance, has used it to develop a drone suitable for service in the harsh conditions of the Antarctic. Drones made by traditional manufacturing processes can’t operate in such extreme climates. What’s more, the Navy’s 3D-printed model has actually proved cheaper than those made by conventional means.

And in a very different arena, FICEP Steel Surface Systems is using digital production technology to improve the performance of steel used in major building projects like The Shard.

Strengths and weaknesses

Here in the UK, the digital production sector has a genuine opportunity to stake its claim as a leader in the new global manufacturing order.

Recent research from HP and A.T. Kearney places Great Britain among the top five countries globally in terms of its readiness for 3D printing. The study of 30 countries ranks the UK second in Europe, behind only the industrial powerhouse that is Germany. And it suggests that our competitiveness could improve even further, as we have the world’s third fastest-growing 3D printing market.

But at the same time, there are issues that must be addressed. The report puts the UK workforce outside the top ten internationally for the digital manufacturing capabilities that will enable 3D printing to flourish.

Despite this skills shortage, I’m convinced that digital production technology presents a once-in-a-lifetime opportunity for our economy. But to make it happen, the country’s 3D printing ecosystem must come together as a whole. Technologists, designers, manufacturers, researchers, device-makers, educators and government: all have a vital part to play in bolstering the 3D printing industry in the UK, and making digital production technology accessible to Britain’s businesses.

George Brasher is UK managing director at HP

- Interested in 3D printing? Find out how this technology is making it more economical to build homes in the developing world

George Brasher is the UK Managing Director at HP. He has over 25 years of working experience. . He is thoughtful, creative and steady handed. Despite the challenges, George has always displayed a willingness to understand all possible options to deliver the best outcome

Most Popular