3D printers could help your train run on time

Mobile repair carriage concept combines a robotic arm with 3D printing

In the future, the majority of repairs on railway lines in the UK could be carried out by robotic 3D printers, and such a system of more efficient repairs could help trains run on time.

At least that’s the vision of Amey, the infrastructural support provider which holds rail repair (and construction) contracts for Network Rail (across London, the East Midlands, and North West of England).

- Watch the largest 3D-printed building in the world being constructed

- Huge 3D printers could produce Mars-bound rockets soon

- These are the best 3D printers of 2019

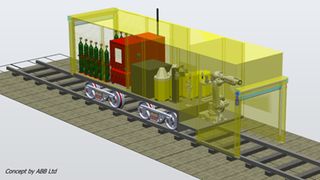

As 3D Printing Industry reports, the idea would be to combine a robotic arm with 3D printing in a mobile repair carriage that could move along railway lines and deliver repairs where needed, or even replace entire sections of train track.

The plans are still in their early stages, with some concept drawings provided by ABB, a Switzerland-based robotic arm manufacturer – see the image at the top – but Amey believes that over 60% of UK railway lines could eventually be serviced in such a manner.

Initially, the focus would be on track renewals – tackling problems with switches and crossings – and the repair system would be quicker and more efficient than current methods, not to mention safer for the people working on the rails.

As smaller refurbishment jobs could be completed more swiftly, rail routes wouldn’t have to be closed for as long. And with repairs being made more regularly on an ongoing basis throughout the rail network, trains will hopefully be less likely to encounter problems in their daily running.

Safe and sustainable

Simon Grundy, Innovation Manager, Consulting & Rail at Amey, observed: “The 190,000 people working on the UK’s railways go above and beyond to ensure that the network is kept running. However, every second they are on the tracks, they are at risk.”

Are you a pro? Subscribe to our newsletter

Sign up to the TechRadar Pro newsletter to get all the top news, opinion, features and guidance your business needs to succeed!

He further observes: “3D printing will remove our people from harm, as renewals previously done by manually removing track, will now be done automatically, in situ using robotics. Not only will this dramatically reduce accidents, the same staff will be upskilled to operate this new technology, futureproofing our workforce.”

The further financial benefit would be savings which are estimated to the tune of over £40 million per year for the UK rail network.

Grundy notes: “Investment in 3D printing is also an investment in sustainability. Large pieces of track previously scrapped will now be repurposed on site, drastically reducing material waste and lowering our carbon footprint. This allows the rail industry to make a significant contribution towards helping the UK government achieve its net zero target by 2050.”

Darren is a freelancer writing news and features for TechRadar (and occasionally T3) across a broad range of computing topics including CPUs, GPUs, various other hardware, VPNs, antivirus and more. He has written about tech for the best part of three decades, and writes books in his spare time (his debut novel - 'I Know What You Did Last Supper' - was published by Hachette UK in 2013).