Faraday cages, drop tests and fake pockets: how your smartphone is made

The weird and wonderful world of phone manufacturing revealed

Downstairs was where the packing took place. We watched as the freshly assembled motherboard was packed into a plastic casing and then tested to make sure the electronic components of the phone worked as they should. Each phone goes through a process called multi-function testing.

This tests a handset's touchscreen, GPS, ariel and sound quality. These are then packed and another Roomba-like robot takes the handsets away for shipping.

Testing times

As you would expect in any factory, this is a seamless process. In total, the SMT and testing took around 30 minutes and then there was a further 10 minutes for final assembly. In all there are 34 people that have a part to play in the assembling of every single handset (and let's not forget that one robot).

There were many other areas of the vast factory that we visited (and many others that were completely out of bounds). Perhaps the most interesting, though, was where more intensive phone testing took place. Spot testing is done on one handset in every 10,000 units and these handsets are put through some hefty rigmarole.

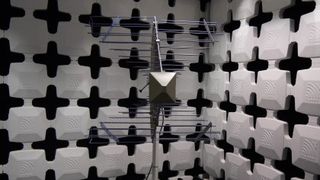

Some examples we saw included a room which acts as a Faraday cage. In it housed a massive antenna that consistently checks the electronic emissions from a phone. The idea of this is to see how well a phone copes with external electronic interference.

And then there's the drop test. A chosen handset is continuously dropped 1.5 metres onto marble to see if it can survive being dropped on the hardest surfaces.

There was also a mini drop test. We watched as a handset was dropped just a few centimetre over and over again - around the same height of your pocket to the floor when sitting on a chair - and this is done 9,000 times to see how durable the handset is. There is also something called the interference test, which simulates a phone being in someone's pocket.

Get daily insight, inspiration and deals in your inbox

Get the hottest deals available in your inbox plus news, reviews, opinion, analysis and more from the TechRadar team.

Each sample has to go through three stages of testing: engineering, design and production. There's on average 50 tests in total with others including: vibration, battery, surviving salt and mist spray, headphone and USB tests and one where a phone is put into a room of 65 degrees celsius to see if it still works properly.

It's not until you see a phone being assembled do you truly understand what goes into making our favourite gadgets.

Seeing the effort that goes into making sure your phone doesn't smash when it falls out of your pocket may not stop the frustration when the screen does actually crack, but it at least we are now safe in the knowledge that the manufacturer tried its best to stop such things from happening.

- 1

- 2

Current page: Going downstairs: packing and testing

Prev Page This is how your smartphone is madeMarc Chacksfield is the Editor In Chief, Shortlist.com at DC Thomson. He started out life as a movie writer for numerous (now defunct) magazines and soon found himself online - editing a gaggle of gadget sites, including TechRadar, Digital Camera World and Tom's Guide UK. At Shortlist you'll find him mostly writing about movies and tech, so no change there then.